Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Logout

Item(s) successfully added to cart

View Cart

View Cart

Powerful tooling solutions on sale now. Shop Now

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Solid End Milling

- /

- High-Performance End Mills

- /

- VariMill™

- /

- VariMill II • Series 57N8 • Square End • Non-Center Cutting • Neck • 5 Flute • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

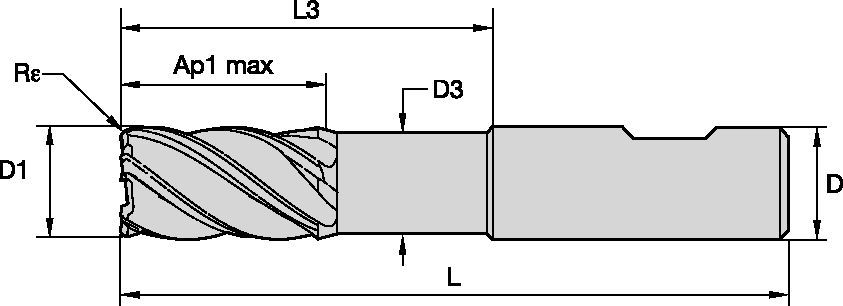

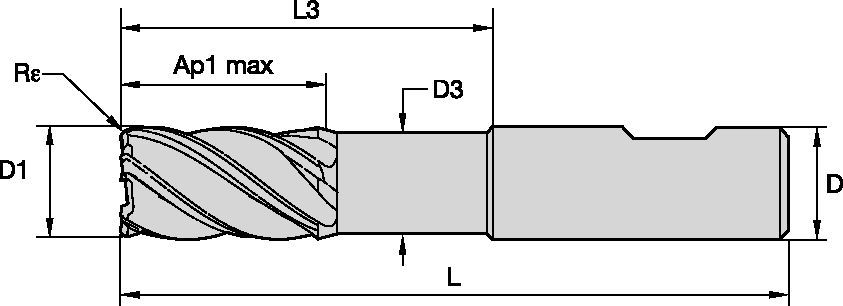

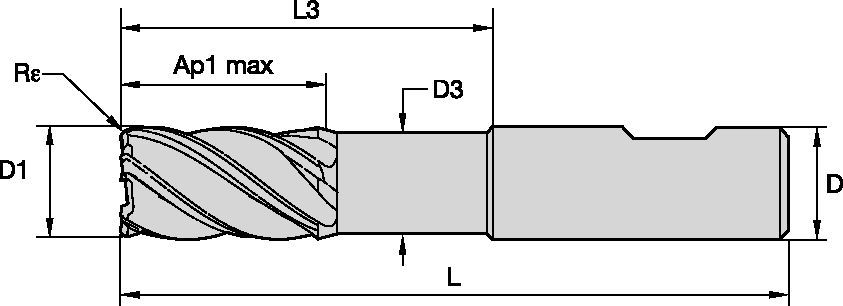

VariMill II • Series 57N8 • Square End • Non-Center Cutting • Neck • 5 Flute • Metric

VariMill™

Features and benefits

- Unequal flute spacing.

- Non-center cutting.

- Maximum ramp angle = 3°.

- Optimized geometry for titanium machining.

- Single tool for both roughing and finishing operations requiring fewer setups.

- Slotting up to 1 x D.

- Standard items listed. Additional styles and coatings made to order.

Uses and application

Trochoidal Milling

Ramping: Blank

Slotting: Square End

Corner Style: Corner Radius

Corner Style: Square End

Shank - Cylindrical Plain

Side Milling/Shoulder Milling: Square End

Helix Angle: 38°

Tool Dimensions: Flute Configuration: 5

Application Data • VariMill II™ • Series 57N8 • Metric

|  |  | |||||||||||||

| A | B | WS15PE | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||

| Cutting Speed | D1 | ||||||||||||||

| Material | ap | ae | ap | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 1 | 1,5 x D | 0,5 x D | 1 x D | 150 | – | 200 | fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 140 | – | 190 | fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 120 | – | 160 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 4 | 1,5 x D | 0,5 x D | 0,75 x D | 90 | – | 150 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 | |

| 5 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 100 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 6 | 1,5 x D | 0,5 x D | 0,75 x D | 50 | – | 75 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| M | 1 | 1,5 x D | 0,5 x D | 1 x D | 90 | – | 115 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 80 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 70 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| K | 1 | 1,5 x D | 0,5 x D | 1 x D | 120 | – | 150 | fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 110 | – | 130 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 100 | – | 130 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| S | 1 | 1,5 x D | 0,3 x D | 0,3 x D | 50 | – | 90 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 4 | 1,5 x D | 0,5 x D | 1 x D | 50 | – | 60 | fz | 0,026 | 0,037 | 0,045 | 0,052 | 0,064 | 0,074 | 0,084 | |

| H | 1 | 1,5 x D | 0,5 x D | 0,75 x D | 80 | – | 140 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 |