Produkt ähnlich wie:

Top Cut 4 • 3 x D • SLR-Schaft • Metrisch

TC4 • 3 x D • SLR-Schäfte • Metrisch

Material Nummer5537944

ISO Katalog NummerTCF300R3SLR32MEANSI Katalog NummerTCF300R3SLR32ME

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

- .caption

Zylinderschaft – mit Spannfläche

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Bohren: Konvexe Eintrittsfläche

Innere Kühlmittelzuführung: Radial: Bohren mit Wendeschneidplatten

Bohren: Sacklochbohrung

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

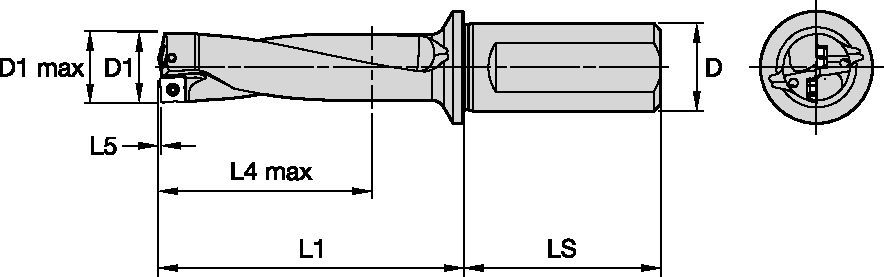

| Material Nummer | 5537944 |

| ISO Katalog Nummer | TCF300R3SLR32ME |

| ANSI Katalog Nummer | TCF300R3SLR32ME |

| [D1] Bohrerdurchmesser M | 30 mm |

| [D1] Bohrerdurchmesser M | 1.1811 in |

| [D1MAX] Bohrerdurchmesser max. | 31 mm |

| [D1MAX] Bohrerdurchmesser max. | 1.2205 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 32 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 1.2598 in |

| [L1] Messlänge der Wendeschneidplatte | 123.09 mm |

| [L1] Messlänge der Wendeschneidplatte | 4.8461 in |

| [L4] Maximale Bohrtiefe | 91.09 mm |

| [L4] Maximale Bohrtiefe | 3.586 in |

| [L5] Bohrerspitzenlänge | 1.09 mm |

| [L5] Bohrerspitzenlänge | 0.0429 in |

| [LS] Schaftlänge | 60 mm |

| [LS] Schaftlänge | 2.3622 in |

| [SSC] Wendeschneidplatten-Sitz-Größe | E |

| Wendeschneidplatten-Größe | TCF100408EP |

| Maß-Wendeschneidplatte 2 | TCF120405EC |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

- .caption

Uses and application

Zylinderschaft – mit Spannfläche

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Bohren: Konvexe Eintrittsfläche

Innere Kühlmittelzuführung: Radial: Bohren mit Wendeschneidplatten

Bohren: Sacklochbohrung

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Features and benefits

- Tool body shipped with insert wrench

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | |||||||

| innen | außen | Min. | Startwert | Max. | |||||||

| –V38 | 0,06–0,08 | 0,08–0,11 | 0,10–0,13 | 0,11–0,14 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/U | – | – | 0,07–0,10 | 0,08–0,10 | |

| –V38 | 0,06–0,10 | 0,08–0,13 | 0,10–0,15 | 0,11–0,16 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/U | – | – | 0,07–0,11 | 0,08–0,11 | |

| –V34 | 0,06–0,10 | 0,08–0,15 | 0,10–0,16 | 0,11–0,17 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,07–0,12 | 0,08–0,13 | |

| –V34 | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 | |||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | – | – | 0,08–0,13 | 0,09–0,15 | |

| –V34 | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,08–0,13 | 0,09–0,15 | |

| –V36 | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,07–0,11 | 0,08–0,12 | |

| 0,06-0,10 | 0,08-0,14 | 0,10-0,15 | 0,11-0,16 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 130 | 165 | mm/U | – | – | 0,07-0,11 | 0,08-0,12 | |

| 0,06-0,11 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 130 | 190 | mm/U | – | – | 0,06-0,09 | 0,07-0,10 | |

| –V38 | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 | |||||||

| –DU | WU20PH | WU20PH | 110 | 140 | 190 | mm/U | – | – | 0,06–0,09 | 0,07–0,10 | |

| 0,06-0,10 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 100 | 160 | mm/U | – | – | 0,06-0,09 | 0,07-0,10 | |

| 0,08-0,14 | 0,08-0,16 | 0,10-0,18 | 0,12-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | – | – | 0,07-0,13 | 0,09-0,18 | |

| –V34 | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 | |||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/U | – | – | 0,07–0,13 | 0,09–0,18 | |

| 0,08-0,14 | 0,08-0,16 | 0,10-0,18 | 0,12-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 190 | mm/U | – | – | 0,07-0,13 | 0,09-0,18 | |

| 0,06-0,10 | 0,08-0,14 | 0,10-0,15 | 0,11-0,16 | ||||||||

| –V36 | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | |||||||

| 0,06-0,10 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| 0,08-0,12 | 0,08-0,13 | 0,10-0,15 | 0,12-0,19 | ||||||||

| –DU | WU20PH | WU20PH | 20 | 30 | 40 | mm/U | – | – | 0,07-0,11 | 0,09-0,14 | |

| –V38 | 0,08–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | |||||||

| –DU | WU20PH | WU20PH | 30 | 40 | 60 | mm/U | – | – | 0,07–0,11 | 0,09–0,14 | |

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | |||||||

| innen | außen | Min. | Startwert | Max. | |||||||

| –V38 | 0,13–0,16 | 0,15–0,18 | 0,16–0,23 | 0,17–0,24 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,12 | 0,11–0,13 | – | – | |

| –V38 | 0,13–0,17 | 0,15–0,19 | 0,16–0,24 | 0,17–0,25 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,13 | 0,11–0,14 | – | – | |

| –V34 | 0,13–0,20 | 0,15–0,21 | 0,16–0,28 | 0,17–0,30 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | 0,09–0,15 | 0,11–0,15 | – | – | |

| –V34 | 0,16–0,24 | 0,16–0,24 | 0,18–0,30 | 0,19–0,32 | |||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 250 | mm/U | 0,12–0,16 | 0,12–0,18 | – | – | |

| –V34 | 0,14–0,22 | 0,16–0,24 | 0,18–0,30 | 0,19–0,32 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 250 | mm/U | 0,12–0,16 | 0,12–0,18 | – | – | |

| –V36 | 0,13–0,18 | 0,15–0,20 | 0,16–0,28 | 0,17–0,30 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,13 | 0,11–0,15 | – | – | |

| 0,13-0,18 | 0,15–0,20 | 0,16-0,28 | 0,17–0,29 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 120 | 160 | mm/U | 0,09-0,13 | 0,11-0,15 | – | – | |

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 120 | 190 | mm/U | 0,09-0,13 | 0,10-0,15 | – | – | |

| –V38 | 0,12–0,17 | 0,14–0,21 | 0,16–0,23 | 0,16–0,24 | |||||||

| –DU | WU20PH | WU20PH | 90 | 110 | 160 | mm/U | 0,09–0,13 | 0,10–0,15 | – | – | |

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 90 | 160 | mm/U | 0,09-0,13 | 0,10-0,15 | – | – | |

| 0,14-0,26 | 0,16-0,30 | 0,18-0,32 | 0,20-0,36 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | 0,10-0,19 | 0,12-0,22 | – | – | |

| –V34 | 0,14–0,26 | 0,16–0,30 | 0,18–0,32 | 0,20–0,36 | |||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/U | 0,10–0,19 | 0,12–0,22 | – | – | |

| 0,14-0,26 | 0,16-0,30 | 0,18-0,32 | 0,20-0,36 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 130 | 190 | mm/U | 0,10-0,19 | 0,12-0,22 | – | – | |

| 0,13-0,18 | 0,15–0,20 | 0,16-0,28 | 0,17-0,30 | ||||||||

| –V36 | 0,13–0,18 | 0,15–0,20 | 0,16–0,28 | 0,17–0,30 | |||||||

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| 0,14-0,21 | 0,16-0,24 | 0,18-0,26 | 0,20-0,30 | ||||||||

| –DU | WU20PH | WU20PH | 20 | 25 | 40 | mm/U | 0,10-0,15 | 0,12-0,18 | – | – | |

| –V38 | 0,14–0,21 | 0,16–0,24 | 0,18–0,26 | 0,20–0,30 | |||||||

| –DU | WU20PH | WU20PH | 30 | 35 | 50 | mm/U | 0,10–0,15 | 0,12–0,18 | – | – | |

| Avanzamento al giro consigliato | |||||||||||

| Sorte | Schnittgeschwindigkeit | ||||||||||

| Werkstoffgruppe | Geometrie | innen | außen | Min. | Startwert | Max. | Werkzeugdurchmesser | 12,00 | 14,00 | 19,00 | 24,00 |

| P0 | –V38 | WU40PH | WU25CH | 120 | 180 | 260 | mm/rev | 0,06–0,08 | 0,08–0,11 | 0,10–0,13 | 0,11–0,14 |

| P0 | –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/rev | – | – | 0.07–0.10 | 0.08–0.10 |

| P1 | –V38 | WU40PH | WU25CH | 120 | 180 | 260 | mm/rev | 0,06–0,10 | 0,08–0,13 | 0,10–0,15 | 0,11–0,16 |

| P1 | –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/rev | – | – | 0.07–0.11 | 0.08–0.11 |

| P2 | –V34 | WU40PH | WU25CH | 120 | 190 | 280 | mm/rev | 0,06–0,10 | 0,08–0,15 | 0,10–0,16 | 0,11–0,17 |

| P2 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.07–0.12 | 0.08–0.13 |

| P3 | –V34 | WU40PH | WPK10CH | 120 | 200 | 310 | mm/rev | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 |

| P3 | –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/rev | – | – | 0.08–0.13 | 0.09–0.15 |

| P4 | –V34 | WU40PH | WPK10CH | 120 | 190 | 310 | mm/rev | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 |

| P4 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.08–0.13 | 0.09–0.15 |

| P5 | –V36 | WU40PH | WU25CH | 120 | 180 | 250 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| P5 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.07–0.11 | 0.08–0.12 |

| P6 | -V36 | WU40PH | WU25CH | 120 | 160 | 210 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| P6 | –DU | WU20PH | WU20PH | 90 | 130 | 165 | mm/rev | – | – | 0.07–0.11 | 0.08–0.12 |

| M1 | -V38 | WU40PH | WU40PH | 120 | 160 | 240 | mm/rev | 0,06–0,11 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M1 | –DU | WU20PH | WU20PH | 90 | 130 | 190 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| M2 | –V38 | WU40PH | WU40PH | 110 | 140 | 210 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M2 | –DU | WU20PH | WU20PH | 110 | 140 | 190 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| M3 | -V36 | WU40PH | WU40PH | 100 | 120 | 200 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M3 | –DU | WU20PH | WU20PH | 80 | 100 | 160 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| K1 | -V34 | WU25CH | WPK10CH | 120 | 200 | 280 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K1 | –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| K2 | –V34 | WU40PH | WPK10CH | 100 | 180 | 260 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K2 | –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| K3 | -V34 | WU40PH | WPK10CH | 100 | 170 | 240 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K3 | –DU | WU20PH | WU20PH | 80 | 140 | 190 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| N1 | -V36 | WN10PH | WN10PH | 250 | 350 | 500 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| N2 | –V36 | WN10PH | WN10PH | 150 | 300 | 450 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| N3 | -V36 | WN10PH | WN10PH | 80 | 120 | 150 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| S3 | -V38 | WU40PH | WU40PH | 20 | 30 | 45 | mm/rev | 0,08–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 |

| S3 | –DU | WU20PH | WU20PH | 20 | 30 | 40 | mm/rev | – | – | 0.07–0.11 | 0.09–0.14 |

| S4 | –V38 | WU40PH | WU40PH | 35 | 40 | 65 | mm/rev | 0,08–0,12 | 0,08–0,13 | 0,10 –0,15 | 0,12–0,19 |

| S4 | –DU | WU20PH | WU20PH | 30 | 40 | 60 | mm/rev | – | – | 0.07–0.11 | 0.09–0.14 |

| Wendeschneidplatten-Größe | Durchmesser- bereich mm (in) | 2 x D/3 x D | 4 x D | 5 x D | ||||||

| X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | ||

| A | 12,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| B | 14,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| C | 19,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| D | 24,00 | 0,8 | D1 + 1,6 mm | +/-0,20 | 0,8 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| E | 30,00 | 0,8 | D1 + 1,6 mm | +/-0,20 | 0,8 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| F | 37,00 | 0,8 | D1 + 1,6 mm | +/-0,25 | 0,8 | D1 + 1 mm | +/-0,38 | +/-0,38 | ||

| G | 46,00 | 1 | D1 + 2 mm | +/-0,25 | 0,8 | D1 + 1 mm | +/-0,38 | +/-0,38 | ||

| H | 57,00 | 1 | D1 + 2 mm | +/-0,28 | 0,8 | D1 + 1 mm | +/-0,42 | +/-0,42 | ||

| Wendeschneidplatten-Größe | Durchmesserbereich (mm) | 2 x D und 3 x D | 4 x D | 5 x D | |||

| X-Versatzwert | D1 max. | X-Versatzwert | D1 max. | X-Versatz | D1 max. | ||

| A | 12,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| B | 14,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| C | 19,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| D | 24,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| E | 30,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| F | 37,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| G | 46,00 | 1 | D1 + 2mm | 0,8 | D1 + 1mm | ||

| H | 57,00 | 1 | D1 + 2mm | 0,8 | D1 + 1mm | ||

| Wendeschneidplatten-Größe | Durchmesser- bereich mm (in) | 2 x D/3 x D | 4 x D | 5 x D | |||||

| D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | ||

| A | 12,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| B | 14,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| C | 19,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| D | 24,00 | D1 + 1,6mm | +/- 0,20 | 0,8 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| E | 30,00 | D1 + 1,6mm | +/- 0,20 | 0,8 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| F | 37,00 | D1 + 1,6mm | +/- 0,25 | 0,8 | D1 + 1mm | +/- 0,38 | +/- 0,38 | ||

| G | 46,00 | D1 + 2mm | +/- 0,25 | 0,8 | D1 + 1mm | +/- 0,38 | +/- 0,38 | ||

| H | 57,00 | D1 + 2mm | +/- 0,28 | 0,8 | D1 + 1mm | +/- 0,42 | +/- 0,42 | ||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | 1,188 | 1,469 | 1,813 | 2,250 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0053 | 0.0063 | 0.0071 | 0.0075 |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0075 |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| Empfohlener Vorschub pro Umdrehung | |||||||||||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | 0,473 | 0,563 | 0,750 | 0,969 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024 | 0.0031 | 0,0039 | 0.0043 |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0031 | 0.0039 | 0.0043 | 0.0047 |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0031 | 0.0039 | 0.0043 | 0.0047 |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| Recommended Feed Rate per Revolution | |||||||||||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | .473 | .563 | .750 | .969 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024–0.0031 | 0.0031–0.0043 | 0.0039–0.0051 | 0.0043–0.0055 |

| – DU | WU20PH | WU20PH | 290 | 430 | 625 | IPR | – | – | 0.0031–0.0041 | 0.0034–0.0044 | |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024–0.0039 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0043–0.0063 |

| – DU | WU20PH | WU20PH | 290 | 430 | 625 | IPR | – | – | 0.0031–0.0047 | 0.0034–0.0050 | |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0024–0.0039 | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0067 |

| – DU | WU20PH | WU20PH | 290 | 450 | 675 | IPR | – | – | 0.0031–0.0050 | 0.0034–0.0054 | |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0071 | 0.0047–0.0079 |

| – DU | WU20PH | WU20PH | 290 | 480 | 745 | IPR | – | – | 0.0034–0.0067 | 0.0037–0.0063 | |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0071 | 0.0047–0.0079 |

| – DU | WU20PH | WU20PH | 290 | 450 | 745 | IPR | – | – | 0.0034–0.0067 | 0.0037–0.0063 | |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| – DU | WU20PH | WU20PH | 290 | 430 | 600 | IPR | – | – | 0.0031–0.0047 | 0.0034–0.0050 | |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| -V36 | WU40PH | WU25CH | 290 | 385 | 500 | IPR | - | - | 0.0031-0.0047 | 0.0034-0.0050 | |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| - DU | WU20PH | WU20PH | 290 | 385 | 575 | IPR | - | - | 0.0025-0.0047 | 0.0031-0.0050 | |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| – DU | WU20PH | WU20PH | 265 | 340 | 500 | IPR | – | – | 0.0025–0.0047 | 0.0031–0.0050 | |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| - DU | WU20PH | WU20PH | 240 | 290 | 480 | IPR | - | - | 0.0025-0.0047 | 0.0031-0.0050 | |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| - DU | WU20PH | WU20PH | 290 | 480 | 675 | IPR | - | - | 0.0031-0.0057 | 0.0038-0.0075 | |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| – DU | WU20PH | WU20PH | 240 | 430 | 625 | IPR | – | – | 0.0031–0.0057 | 0.0038–0.0075 | |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| - DU | WU20PH | WU20PH | 240 | 400 | 575 | IPR | - | - | 0.0031-0.0057 | 0.0038-0.0075 | |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0024–0.0039 | 0.0028–0.0043 | 0.0031–0.0047 | 0.0039–0.0055 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0031–0.0047 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0047–0.0075 |

| - DU | WU20PH | WU20PH | 50 | 70 | 100 | IPR | - | - | 0.0031-0.0047 | 0.0038-0.006 | |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0031–0.0047 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0047–0.0075 |

| – DU | WU20PH | WU20PH | 85 | 95 | 150 | IPR | – | – | 0.0031–0.0047 | 0.0038–0.006 | |

Insert Selection

TC4 • Auswahlhilfe für Wendeschneidplatten

| Werkstoffgruppe | Geometrie | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| Wende- schneidplatte Außen | Wende- schneidplatte Innen | Wende- schneidplatte Außen | Wende- schneidplatte Innen | Wende- schneidplatte Außen | Wende- schneidplatte Innen | ||

| P1 | V38/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| P2–P4 | V34/DU | WPK10CH | WU40PH/WU20PH | WU25CH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| P5–P6 | V36/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| M1–M3 | V36/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| K1–K3 | V34/DU | WPK10CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| N1–N4 | V36 | WN10PH | WN10PH | WN10PH | WN10PH | WN10PH | WN10PH |

| S1–S4 | V38/DU | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data