Produkt ähnlich wie:

VSM11™ • XDPT-MM

Wendeschneidplatten • XDPT-MM

Material Nummer6180148

ISO Katalog NummerXDPT110408PDSRMMASI Katalog NummerXDPT1102SRMM

- P Stahl

- M Rostfreier Stahl

- N NE-Metalle

- S Hochwarmfeste Legierungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

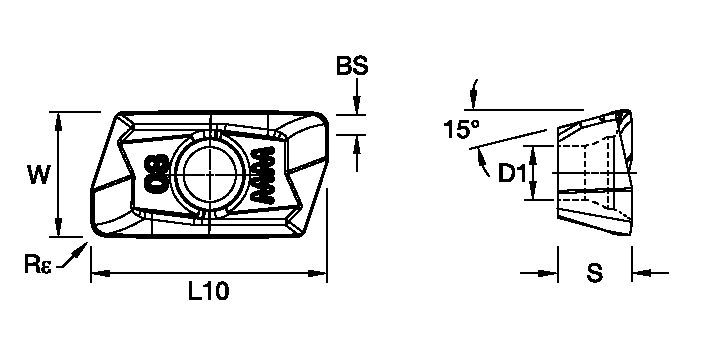

| Material Nummer | 6180148 |

| ISO Katalog Nummer | XDPT110408PDSRMM |

| ASI Katalog Nummer | XDPT1102SRMM |

| Sorte | WS40PM |

| Schneidkanten pro Wendeschneidplatte | 2 |

| [LI] Wendeschneidplattenlänge | 13.499 mm |

| [LI] Wendeschneidplattenlänge | 0.5315 in |

| [BS] Eckflächenlänge | 1.66 mm |

| [BS] Eckflächenlänge | 0.065 in |

| [S] Dicke der Wendeschneidplatte | 4.134 mm |

| [S] Dicke der Wendeschneidplatte | 0.1628 in |

| [W] Schneideinsatzbreite | 6.895 mm |

| [W] Schneideinsatzbreite | 0.2714 in |

| [Rε] Eckenradius | 0.775 mm |

| [Rε] Eckenradius | 0.031 in |

| Mittlere Spandicke [HM] | 0.063 mm |

| Mittlere Spandicke [HM] | 0.0025 in |

Werkstoffe

- Stahl

- Rostfreier Stahl

- NE-Metalle

- Hochwarmfeste Legierungen

Features and benefits

- -MM ist eine Geometrie für die mittlere Bearbeitung bis zur Schruppbearbeitung und die erste Wahl für allgemeine und Universalanwendungen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

Empfohlene Startwerte für Vorschübe [mm]

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..PCD | 0,12 | 0,18 | 0,29 | 0,08 | 0,13 | 0,21 | 0,06 | 0,10 | 0,16 | 0,06 | 0,09 | 0,14 | 0,05 | 0,08 | 0,12 | .F..PCD |

| .F..ALP | 0,12 | 0,22 | 0,31 | 0,08 | 0,16 | 0,23 | 0,06 | 0,12 | 0,17 | 0,06 | 0,10 | 0,15 | 0,05 | 0,10 | 0,14 | .F..ALP |

| .E..ML | 0,17 | 0,27 | 0,36 | 0,13 | 0,20 | 0,26 | 0,10 | 0,15 | 0,19 | 0,08 | 0,13 | 0,17 | 0,08 | 0,12 | 0,16 | .E..ML |

| .S..MM/.S..MU | 0,23 | 0,32 | 0,47 | 0,17 | 0,23 | 0,34 | 0,13 | 0,17 | 0,25 | 0,11 | 0,15 | 0,22 | 0,10 | 0,14 | 0,20 | .S..MM/.S..MU |

| .S..MH | 0,23 | 0,37 | 0,56 | 0,17 | 0,27 | 0,40 | 0,13 | 0,20 | 0,30 | 0,11 | 0,17 | 0,26 | 0,10 | 0,16 | 0,24 | .S..MH |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Empfohlener Anfangsvorschub [IPT]

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| .F..PCD | .005 | .007 | .011 | .003 | .005 | .008 | .003 | .004 | .006 | .002 | .003 | .005 | .002 | .003 | .005 | .F..PCD |

| .F..ALP | .005 | .009 | .013 | .003 | .006 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | .F..ALP |

| .E..ML | .007 | .011 | .014 | .005 | .008 | .010 | .004 | .006 | .008 | .003 | .005 | .007 | .003 | .005 | .006 | .E..ML |

| .S..MM/.S..MU | .009 | .013 | .019 | .007 | .009 | .013 | .005 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .008 | .S..MM/.S..MU |

| .S..MH | .009 | .014 | .022 | .007 | .010 | .016 | .005 | .008 | .012 | .004 | .007 | .010 | .004 | .006 | .009 | .S..MH |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Empfohlene Start-Schnittgeschwindigkeiten und Vorschübe [m/min]*

| Werkstoffgruppe | WDN10U | WK15CM | WK15PM | WK15PM | WN10HM | WN25PM | WP25PM | |||||||||||||||

| P | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 330 | 285 | 270 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 275 | 240 | 200 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 255 | 215 | 175 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 225 | 185 | 150 | |

| 5 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 185 | 170 | 150 | |

| 6 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 165 | 125 | 100 | |

| M | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 205 | 180 | 165 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 185 | 160 | 130 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 140 | 120 | 95 | |

| K | 1 | — | — | — | 420 | 385 | 340 | 270 | 245 | 215 | 360 | 290 | 245 | — | — | — | — | — | — | 230 | 205 | 185 |

| 2 | — | — | — | 335 | 295 | 275 | 210 | 190 | 175 | 280 | 230 | 195 | — | — | — | — | — | — | 180 | 160 | 150 | |

| 3 | — | — | — | 280 | 250 | 230 | 175 | 160 | 145 | 210 | 175 | 140 | — | — | — | — | — | — | 150 | 135 | 120 | |

| N | 1 | 4010 | 3505 | 2990 | — | — | — | — | — | — | — | — | — | 795 | 695 | 600 | 1075 | 945 | 875 | — | — | — |

| 2 | 1600 | 1495 | 1400 | — | — | — | — | — | — | — | — | — | 795 | 695 | 600 | 945 | 875 | 760 | — | — | — | |

| 3 | 1600 | 1495 | 1400 | — | — | — | — | — | — | — | — | — | 560 | 485 | 420 | 945 | 875 | 760 | — | — | — | |

| S | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 40 | 35 | 25 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 40 | 35 | 25 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 50 | 40 | 25 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 70 | 50 | 35 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 120 | 90 | 70 |

| Werkstoffgruppe | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WU35PM | |||||||||||||

| P | 1 | 455 | 395 | 370 | 295 | 260 | 245 | — | — | — | — | — | — | 330 | 290 | 270 | 260 | 230 | 215 |

| 2 | 280 | 255 | 230 | 250 | 215 | 180 | — | — | — | — | — | — | 275 | 250 | 200 | 220 | 190 | 160 | |

| 3 | 255 | 230 | 205 | 230 | 195 | 160 | — | — | — | — | — | — | 255 | 220 | 175 | 200 | 170 | 140 | |

| 4 | 190 | 175 | 160 | 205 | 170 | 135 | — | — | — | — | — | — | 225 | 190 | 150 | 180 | 150 | 120 | |

| 5 | 260 | 230 | 210 | 170 | 155 | 135 | — | — | — | 170 | 145 | 120 | 185 | 175 | 150 | 150 | 135 | 120 | |

| 6 | 160 | 135 | 110 | 150 | 115 | 90 | — | — | — | 150 | 110 | 80 | 165 | 130 | 100 | 130 | 100 | 80 | |

| M | 1 | 205 | 185 | 155 | 195 | 170 | 155 | 225 | 200 | 185 | 210 | 170 | 140 | 205 | 180 | 165 | 170 | 150 | 135 |

| 2 | 185 | 160 | 140 | 175 | 150 | 125 | 205 | 180 | 145 | 180 | 145 | 120 | 185 | 160 | 130 | 155 | 130 | 110 | |

| 3 | 145 | 130 | 115 | 130 | 115 | 90 | 155 | 135 | 105 | 145 | 110 | 85 | 140 | 120 | 95 | 115 | 100 | 80 | |

| K | 1 | 295 | 265 | 240 | — | — | — | — | — | — | — | — | — | 250 | 220 | 185 | — | — | — |

| 2 | 235 | 210 | 190 | — | — | — | — | — | — | — | — | — | 200 | 180 | 150 | — | — | — | |

| 3 | 195 | 175 | 160 | — | — | — | — | — | — | — | — | — | 180 | 150 | 120 | — | — | — | |

| N | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 550 | 470 | 400 | — | — | — |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | 550 | 470 | 400 | — | — | — | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | 400 | 350 | 300 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 45 | 40 | 30 | 40 | 35 | 25 | 40 | 35 | 25 | 35 | 30 | 25 |

| 2 | — | — | — | — | — | — | 45 | 40 | 30 | 40 | 35 | 25 | 40 | 35 | 25 | 35 | 30 | 25 | |

| 3 | — | — | — | — | — | — | 55 | 45 | 30 | 50 | 40 | 25 | 50 | 40 | 25 | 45 | 35 | 25 | |

| 4 | — | — | — | — | — | — | 70 | 60 | 40 | 60 | 50 | 30 | 70 | 50 | 35 | 60 | 45 | 30 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 110 | 80 | 70 | — | — | — |

Empfohlene Startwerte für Schnittgeschwindigkeit [SFM]

| Werkstoffgruppe | WDN10U | WK15CM | WK15PM | WK15PM | WN10HM | WN25PM | WP25PM | |||||||||||||||

| P | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 1085 | 935 | 885 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 900 | 785 | 655 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 835 | 705 | 575 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 740 | 605 | 490 | |

| 5 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 605 | 560 | 490 | |

| 6 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 540 | 410 | 330 | |

| M | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 675 | 590 | 540 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 605 | 525 | 425 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 460 | 395 | 310 | |

| K | 1 | — | — | — | 1380 | 1265 | 1115 | 885 | 805 | 705 | 1180 | 950 | 805 | — | — | — | — | — | — | 755 | 675 | 605 |

| 2 | — | — | — | 1100 | 970 | 900 | 690 | 625 | 575 | 920 | 755 | 640 | — | — | — | — | — | — | 590 | 525 | 490 | |

| 3 | — | — | — | 920 | 820 | 755 | 575 | 525 | 475 | 690 | 575 | 460 | — | — | — | — | — | — | 490 | 445 | 395 | |

| N | 1 | 13155 | 11500 | 9810 | — | — | — | — | — | — | — | — | — | 2605 | 2275 | 1965 | 3525 | 3100 | 2870 | — | — | — |

| 2 | 5250 | 4905 | 4595 | — | — | — | — | — | — | — | — | — | 2605 | 2275 | 1965 | 3100 | 2870 | 2495 | — | — | — | |

| 3 | 5250 | 4905 | 4595 | — | — | — | — | — | — | — | — | — | 1835 | 1590 | 1375 | 3100 | 2870 | 2495 | — | — | — | |

| S | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 130 | 115 | 80 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 130 | 115 | 80 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 165 | 130 | 80 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 230 | 165 | 115 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 395 | 295 | 230 |

| Werkstoffgruppe | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WU35PM | |||||||||||||

| P | 1 | 1495 | 1295 | 1215 | 970 | 855 | 805 | — | — | — | — | — | — | 1080 | 950 | 885 | 855 | 755 | 705 |

| 2 | 920 | 835 | 755 | 820 | 705 | 590 | — | — | — | — | — | — | 900 | 820 | 655 | 720 | 625 | 525 | |

| 3 | 835 | 755 | 675 | 755 | 640 | 525 | — | — | — | — | — | — | 835 | 720 | 570 | 655 | 560 | 460 | |

| 4 | 625 | 575 | 525 | 675 | 560 | 445 | — | — | — | — | — | — | 735 | 620 | 490 | 590 | 490 | 395 | |

| 5 | 855 | 755 | 690 | 560 | 510 | 445 | — | — | — | 560 | 475 | 395 | 605 | 570 | 490 | 490 | 445 | 395 | |

| 6 | 525 | 445 | 360 | 490 | 375 | 295 | — | — | — | 490 | 360 | 260 | 540 | 425 | 325 | 425 | 330 | 260 | |

| M | 1 | 675 | 605 | 510 | 640 | 560 | 510 | 740 | 655 | 605 | 690 | 560 | 460 | 670 | 590 | 540 | 560 | 490 | 445 |

| 2 | 605 | 525 | 460 | 575 | 490 | 410 | 675 | 590 | 475 | 590 | 475 | 395 | 605 | 520 | 425 | 510 | 425 | 360 | |

| 3 | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 445 | 345 | 475 | 360 | 280 | 455 | 390 | 310 | 375 | 330 | 260 | |

| K | 1 | 970 | 870 | 785 | — | — | — | — | — | — | — | — | — | 820 | 720 | 605 | — | — | — |

| 2 | 770 | 690 | 625 | — | — | — | — | — | — | — | — | — | 655 | 590 | 490 | — | — | — | |

| 3 | 640 | 575 | 525 | — | — | — | — | — | — | — | — | — | 590 | 490 | 390 | — | — | — | |

| N | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 1800 | 1540 | 1310 | — | — | — |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | 1800 | 1540 | 1310 | — | — | — | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | 1310 | 1145 | 980 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 150 | 130 | 100 | 130 | 115 | 80 | 130 | 110 | 80 | 115 | 100 | 80 |

| 2 | — | — | — | — | — | — | 150 | 130 | 100 | 130 | 115 | 80 | 130 | 110 | 80 | 115 | 100 | 80 | |

| 3 | — | — | — | — | — | — | 180 | 150 | 100 | 165 | 130 | 80 | 160 | 130 | 80 | 150 | 115 | 80 | |

| 4 | — | — | — | — | — | — | 230 | 195 | 130 | 195 | 165 | 100 | 225 | 160 | 110 | 195 | 150 | 100 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 360 | 260 | 225 | — | — | — |

Insert Selection

Auswahlhilfe für Wendeschneidplatten

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Universal | Schruppbearbeitung | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | XDCT-ML | WP40PM | XDPT-MM | WP40PM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| P3–P4 | XDCT-ML | WP40PM | XDPT-MM | WP40PM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| P5–P6 | XDPT-MM | WP25PM | XDPT-MM | WP35CM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| M1–M2 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| M3 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| K1–K2 | XDCT-ML | WK15CM | XDPT-MM | WK15CM | XD..-MU | WU20PM | XDPT-MH | WK15CM |

| K3 | XDCT-ML | WP35CM | XDPT-MM | WP35CM | XD..-MU | WU20PM | XDPT-MH | WP35CM |

| N1–N2 | XDCT-ALP | WN10HM | XDCT-ALP | WN25PM | – | – | XDCT-ALP | WN25PM |

| N3 | XDCW-PCD | WDN10U | XDCW-PCD | WDN10U | – | – | XDCW-PCD | WDN10U |

| S1–S2 | XDCT-ML | WP25PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| S3 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| S4 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| H1 | XDCT-ML | WP25PM | XDPT-MM | WP25PM | XD..-MU | WU20PM | XDPT-MU | WU20PM |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data