Produto semelhante ao:

VariMill™ • 4XC5 • 4XCT • 4-Flute • Inch

VariMill™ • 4XC5 • 4XCT • Asymmetrical Flute Spacing

Número de material6071552

ID do catálogo ISO4XC519SDL20ID do catálogo ANSI4XC519SDL20

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

100029626

100029627

Trochoidal Milling

Fresamento de rampa: blank

Abertura de canal: topo reto

Fresamento lateral/fresamento de canto: topo reto

Ângulo de hélice: 38°

Dimensões da ferramenta: Configuração de canal: 4

Fresamento de mergulho

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

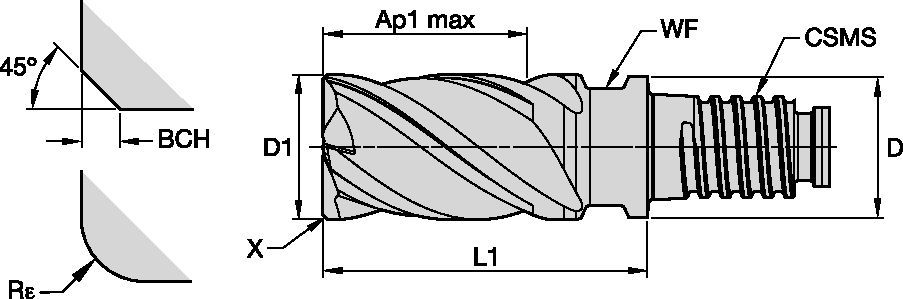

| Número de material | 6071552 |

| ID do catálogo ISO | 4XC519SDL20 |

| ID do catálogo ANSI | 4XC519SDL20 |

| Grade | WP15PE |

| Adapter Style Machine Side | DUO-LOCK |

| [D] Adapter / Shank / Bore Diameter | 18.55 mm |

| [D] Adapter / Shank / Bore Diameter | 0.7307 in |

| [L1] Gage Length | 42.9 mm |

| [L1] Gage Length | 1.689 in |

| [CSMS] System Size Machine Side | DL20 |

| [WF] Width of Flat | 16 mm |

| [WF] Width of Flat | 0.6299 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 19.05 mm |

| [D1] Effective Cutting Diameter | 0.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 28.575 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.125 in |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

100029626

100029627

Trochoidal Milling

Fresamento de rampa: blank

Abertura de canal: topo reto

Fresamento lateral/fresamento de canto: topo reto

Ângulo de hélice: 38°

Dimensões da ferramenta: Configuração de canal: 4

Fresamento de mergulho

Classes

WP15PE

Coated carbide grade with thick PVD coating and optimised chemistry and process for increased wear resistance. Outstanding protection in milling of steels to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Características e benefícios

- Asymmetrical flute spacing minimizes chatter and harmonics for smoother machining.

- Center cutting.

- Single tool for both roughing and finishing operations requiring fewer setups.

- Standard items listed. Additional styles and coatings made-to-order.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Dados de aplicação

VariMill™ • 4XC5 • Asymmetrical Flute Spacing

|  |  | ||||||||||||||||||

| Fresamento lateral (A) e canal (B) | curta | média | longa | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||||

| A | B | alcance do adaptador | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | ||||||||||||||||||

| Velocidade de corte | Velocidade de corte | Velocidade de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| Grupo de material | ap | ae | ap | Mín. | Máx. | Mín. | Máx. | Mín. | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0021 | .0022 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 120 | – | 156 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0028 | .0030 | |

VariMill™ • 4XCT • Asymmetrical Flute Spacing

|  |  | ||||||||||||||||||

| Fresamento lateral (A) e canal (B) | curta | média | longa | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||||

| A | B | alcance do adaptador | D1 | |||||||||||||||||

| WS15PE | WS15PE | WS15PE | ||||||||||||||||||

| Velocidade de corte | Velocidade de corte | Velocidade de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| Grupo de material | ap | ae | ap | Mín. | Máx. | Mín. | Máx. | Mín. | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0021 | .0022 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 120 | – | 156 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0028 | .0030 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 |

| 2 | 1.5 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data