欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称: {{SolutionName}}- 产品

- /

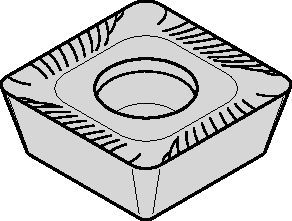

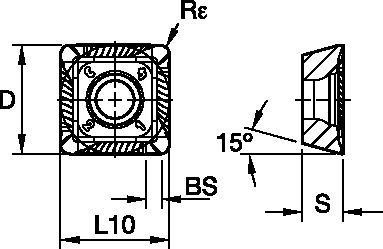

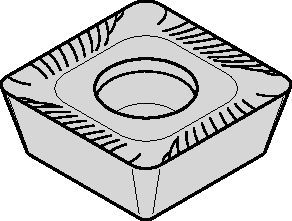

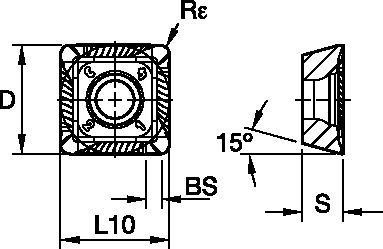

- M690 • SDMT-ML • SD1506..

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

M690 • SDMT-ML • SD1506..

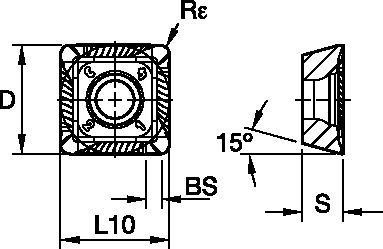

刀片 • SD1506..

刀片选择指南

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P3–P4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P5–P6 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M1–M2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M3 | .E..ML | WS40PM | .S..MM | WS40PM | .S..MH | WP35CM |

| K1–K2 | .E..ML | WK15CM | .E..ML | WK15CM | .S..MH | WK15CM |

| K3 | .E..ML | WK15CM | .S..MM | TN6525 | .S..MH | TN6525 |

| N1–N2 | .ALP | THM-U | .E..ML | THM-U | .S..ML | THM-U |

| N3 | .ALP | THM-U | .E..ML | THM-U | .S..ML | THM-U |

| S1–S2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S3 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| S4 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| H1 | .S..MM | WS30PM | .S..MM | WS30PM | .S..MM | WS30PM |

刀片选择指南

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P3–P4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P5–P6 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M1–M2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M3 | .E..ML | TN6540 | .S..MM | WP35CM | .S..MH | WP35CM |

| K1–K2 | .E..ML | WK15CM | .E..ML | WK15CM | .S..MH | WK15CM |

| K3 | .E..ML | WK15CM | .S..MM | WK15CM | .S..MH | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S3 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| H1 | .S..MM | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

建议的初始进给量 [毫米]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .F..ALP | 0,12 | 0,23 | 0,46 | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | .F..ALP |

| .E..ML | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..ML |

| .S..MM | 0,12 | 0,42 | 0,70 | 0,08 | 0,30 | 0,50 | 0,06 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,05 | 0,18 | 0,30 | .S..MM |

| .S..MH | 0,23 | 0,54 | 0,85 | 0,17 | 0,39 | 0,61 | 0,13 | 0,29 | 0,46 | 0,11 | 0,25 | 0,40 | 0,10 | 0,23 | 0,36 | .S..MH |

| Light

|

General

|

Heavy

|

建议的初始进给量 [毫米]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .F..ALP | 0,12 | 0,23 | 0,46 | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | .F..ALP |

| .E..ML | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..ML |

| .S..MM | 0,12 | 0,42 | 0,70 | 0,08 | 0,30 | 0,50 | 0,06 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,05 | 0,18 | 0,30 | .S..MM |

| .S..MH | 0,23 | 0,54 | 0,85 | 0,17 | 0,39 | 0,61 | 0,13 | 0,29 | 0,46 | 0,11 | 0,25 | 0,40 | 0,10 | 0,23 | 0,36 | .S..MH |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .F..ALP | .005 | .009 | .019 | .003 | .007 | .013 | .003 | .005 | .010 | .002 | .004 | .009 | .002 | .004 | .008 | .F..ALP |

| .E..ML | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .E..ML |

| .S..MM | .005 | .016 | .027 | .003 | .012 | .020 | .003 | .009 | .015 | .002 | .008 | .013 | .002 | .007 | .012 | .S..MM |

| .S..MH | .009 | .021 | .033 | .007 | .015 | .024 | .005 | .011 | .018 | .004 | .010 | .016 | .004 | .009 | .014 | .S..MH |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .E..ML | .007 | .019 | .032 | .005 | .014 | .023 | .004 | .010 | .017 | .003 | .009 | .015 | .003 | .008 | .014 | .E..ML |

| .S..MM | .008 | .021 | .035 | .006 | .015 | .025 | .004 | .011 | .019 | .004 | .010 | .016 | .003 | .009 | .015 | .S..MM |

| .S..MH | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..MH |

| Light

|

General

|

Heavy

|

建议的初始速度 [米/分钟]

| Material Group | TN6520 | TN6525 | TN6540 | WP35CM | |||||||||

| P | 0 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | – | – | – |

| 1 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | 455 | 395 | 370 | |

| 2 | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | 280 | 255 | 230 | |

| 3 | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | 255 | 230 | 205 | |

| 4 | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | 190 | 175 | 160 | |

| 5 | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | 260 | 230 | 210 | |

| 6 | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | 160 | 135 | 110 | |

| M | 1 | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 | 205 | 185 | 155 |

| 2 | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | 185 | 160 | 140 | |

| 3 | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | 145 | 130 | 115 | |

| K | 1 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 | 295 | 265 | 240 |

| 2 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | 235 | 210 | 190 | |

| 3 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 30 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 20 | 15 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 35 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 25 | 20 | 66 | 50 | 33 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | WK15CM | WS30PM | WS40PM | THM-U | |||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – |

| 1 | – | – | – | – | – | – | 280 | 245 | 230 | – | – | – | |

| 2 | – | – | – | – | – | – | 235 | 205 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | 215 | 185 | 150 | – | – | – | |

| 4 | – | – | – | – | – | – | 195 | 160 | 130 | – | – | – | |

| 5 | – | – | – | – | – | – | 160 | 140 | 130 | – | – | – | |

| 6 | – | – | – | – | – | – | 140 | 110 | 85 | – | – | – | |

| M | 1 | – | – | – | 225 | 200 | 185 | 260 | 190 | 115 | – | – | – |

| 2 | – | – | – | 205 | 180 | 145 | 230 | 170 | 105 | – | – | – | |

| 3 | – | – | – | 155 | 135 | 105 | 190 | 140 | 80 | – | – | – | |

| K | 1 | 420 | 385 | 340 | – | – | – | – | – | – | 190 | 170 | 150 |

| 2 | 335 | 295 | 275 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | 1075 | 945 | 945 | 2000 | 1200 | 1000 |

| 2 | – | – | – | – | – | – | 945 | 875 | 845 | 1365 | 815 | 665 | |

| 3 | – | – | – | – | – | – | 875 | 760 | 760 | 800 | 500 | 400 | |

| S | 1 | – | – | – | 45 | 40 | 30 | 62 | 45 | 27 | – | – | – |

| 2 | – | – | – | 45 | 40 | 30 | 55 | 40 | 26 | – | – | – | |

| 3 | – | – | – | 55 | 45 | 30 | 64 | 46 | 29 | – | – | – | |

| 4 | – | – | – | 85 | 60 | 40 | 90 | 66 | 42 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

建议的初始速度 [米/分钟]

| Material Group | TN6520 | TN6525 | TN6540 | WP35CM | |||||||||

| P | 0 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | – | – | – |

| 1 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | 455 | 395 | 370 | |

| 2 | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | 280 | 255 | 230 | |

| 3 | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | 255 | 230 | 205 | |

| 4 | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | 190 | 175 | 160 | |

| 5 | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | 260 | 230 | 210 | |

| 6 | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | 160 | 135 | 110 | |

| M | 1 | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 | 205 | 185 | 155 |

| 2 | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | 185 | 160 | 140 | |

| 3 | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | 145 | 130 | 115 | |

| K | 1 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 | 295 | 265 | 240 |

| 2 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | 235 | 210 | 190 | |

| 3 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 30 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 20 | 15 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 35 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 25 | 20 | 66 | 50 | 33 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | WK15CM | WS30PM | WS40PM | THM-U | |||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – |

| 1 | – | – | – | – | – | – | 280 | 245 | 230 | – | – | – | |

| 2 | – | – | – | – | – | – | 235 | 205 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | 215 | 185 | 150 | – | – | – | |

| 4 | – | – | – | – | – | – | 195 | 160 | 130 | – | – | – | |

| 5 | – | – | – | – | – | – | 160 | 140 | 130 | – | – | – | |

| 6 | – | – | – | – | – | – | 140 | 110 | 85 | – | – | – | |

| M | 1 | – | – | – | 225 | 200 | 185 | 260 | 190 | 115 | – | – | – |

| 2 | – | – | – | 205 | 180 | 145 | 230 | 170 | 105 | – | – | – | |

| 3 | – | – | – | 155 | 135 | 105 | 190 | 140 | 80 | – | – | – | |

| K | 1 | 420 | 385 | 340 | – | – | – | – | – | – | 190 | 170 | 150 |

| 2 | 335 | 295 | 275 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | 1075 | 945 | 945 | 2000 | 1200 | 1000 |

| 2 | – | – | – | – | – | – | 945 | 875 | 845 | 1365 | 815 | 665 | |

| 3 | – | – | – | – | – | – | 875 | 760 | 760 | 800 | 500 | 400 | |

| S | 1 | – | – | – | 45 | 40 | 30 | 62 | 45 | 27 | – | – | – |

| 2 | – | – | – | 45 | 40 | 30 | 55 | 40 | 26 | – | – | – | |

| 3 | – | – | – | 55 | 45 | 30 | 64 | 46 | 29 | – | – | – | |

| 4 | – | – | – | 85 | 60 | 40 | 90 | 66 | 42 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |