Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Výkonná nástrojová řešení v prodeji nyní.

Objednejte nyní.

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Producty

- /

- Indexable Milling

- /

- Drážkovací frézy

- /

- Řada M16

- /

- M16 Series - Inserts

- /

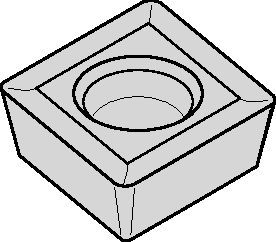

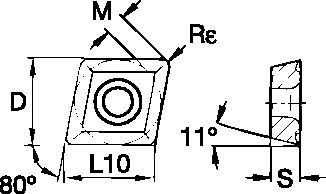

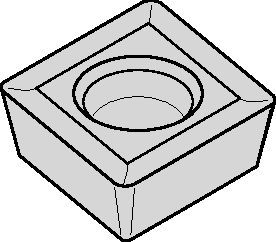

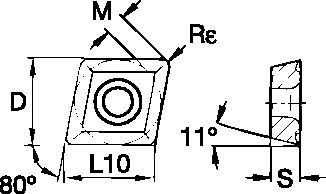

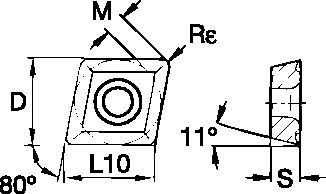

- M16 • CPNT • CP0602..

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

M16 • CPNT • CP0602..

Břitové destičky

Výběr břitové destičky

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | CPNT | WP40PM | CPNT | WP40PM | CPNT | WP40PM |

| P3–P4 | CPNT | WP35CM | CPNT | WP35CM | CPNT | WP35CM |

| P5–P6 | CPNT | WP35CM | CPNT | WP40PM | CPNT | WP40PM |

| M1–M2 | CPNT | WP40PM | CPNT | WP40PM | CPNT | WP40PM |

| M3 | CPNT | TN7535 | CPNT | WP35CM | CPNT | WP35CM |

| K1–K2 | CPNT | WK15CM | CPNT | WK15CM | CPNT | WK15CM |

| K3 | CPNT | WK15CM | CPNT | WP35CM | CPNT | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Doporučené počáteční hodnoty posuvů [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| CPNT06 | 0,12 | 0,29 | 0,46 | 0,09 | 0,21 | 0,33 | 0,07 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT06 |

| CPNT08 | 0,12 | 0,29 | 0,46 | 0,09 | 0,21 | 0,33 | 0,07 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT08 |

| CPNT09 | 0,12 | 0,29 | 0,46 | 0,08 | 0,21 | 0,33 | 0,06 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT09 |

| CPNT12 | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,32 | 0,06 | 0,16 | 0,28 | 0,05 | 0,15 | 0,25 | CPNT12 |

| Light

|

General

|

Heavy

|

Doporučené počáteční řezné rychlosti [m/min]

| Material Group | THM | TTM08 | WK15CM | WP35CM | WP40PM | |||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 |

| 1 | – | – | – | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 | |

| 2 | – | – | – | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | – | – | – | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | – | – | – | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | 205 | 170 | 135 | |

| 5 | – | – | – | – | – | – | – | – | – | 260 | 230 | 210 | 170 | 155 | 135 | |

| 6 | – | – | – | – | – | – | – | – | – | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | – | – | – | – | – | – | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | – | – | – | – | – | – | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | – | – | – | – | – | – | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 120 | 90 | 75 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | – | – | – |

| 2 | 125 | 100 | 70 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | – | – | – | |

| 3 | 130 | 95 | 60 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | – | – | – | |

| N | 1 | 900 | 600 | 500 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | |

| 4 | – | – | – | – | – | – | – | – | – | 66 | 50 | 33 | 65 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |