Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Výkonná nástrojová řešení v prodeji nyní.

Objednejte nyní.

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Producty

- /

- Vrtání

- /

- Monolitní karbidové vrtáky

- /

- Top Drill s rovným čelem

- /

- TDF511A • WU20PD™ • TDF521A • WN15HD™ • Stopka A • 3 x D

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

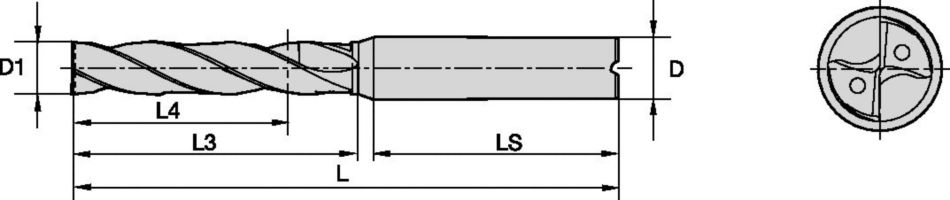

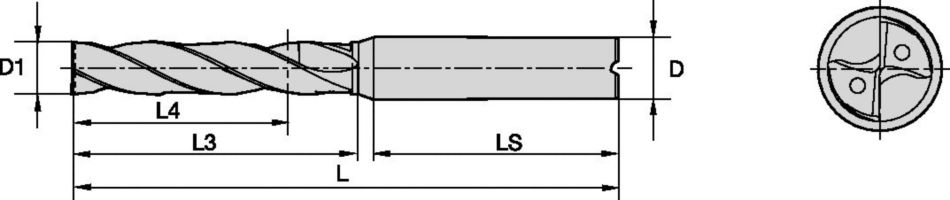

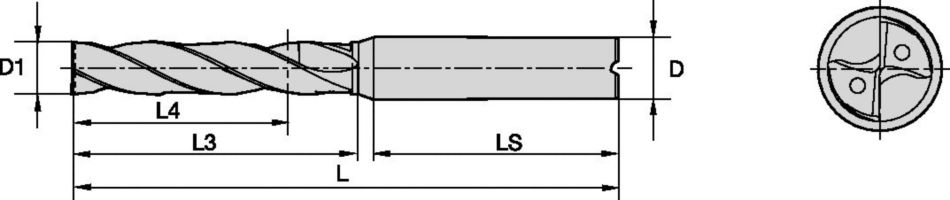

TDF511A • WU20PD™ • TDF521A • WN15HD™ • Stopka A • 3 x D

TOP DRILL FLAT s vnitřním chlazením

Vlastnosti a výhody

- Vrtáky pro otvory s plochým dnem s vnitřním chlazením.

- Karbidové vrtáky navržené pro specifické aplikace snižují počet operací pokud: 1) je požadováno ploché dno, eliminují nutnost použít dodatečné stopkové frézy; 2) je nutná příprava na nakloněné nebo zaoblené ploše.

- Čtyři vodící fazetky zlepšují přímost a kruhovitost otvoru. Vyšší stabilita i při vrtání průniků otvorů.

- Vytváří skutečně rovné dno.

- Dvě sorty pokrývají většinu materiálů obrobků.

Použití

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Drilling: Flat Bottom

Drilling: Stacked Plates

Drilling: Convex

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Corner Style: Corner Chamfer

Corner Style: Square End

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Tool Dimensions: 2flute/4margin/coolant

38550

38563

Drilling Depth: 3x

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Corner Drilling 45°