Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

WIDIA steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Leistungsstarke Werkzeuglösungen jetzt im Angebot.

Bestellen Sie jetzt!

WIDIA steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

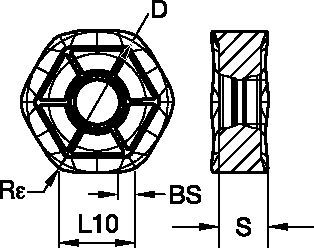

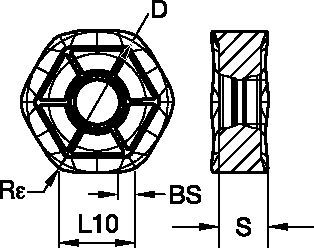

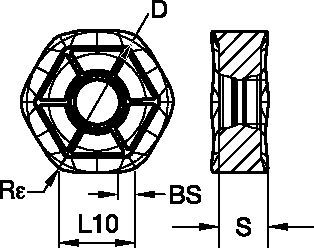

- M1200 • HNGJ-LD • HN0905

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

M1200 • HNGJ-LD • HN0905

15°/75° • 45°• 30°/60° Wendeschneidplatten • HNGJ-LD

Auswahlhilfe für Wendeschneidplatten

| Material Group | Light

|

General

|

Heavy

|

Universal | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..LD | WP40PM | .S..GD | WP40PM | .S..HD | WP40PM | .S..MM | WU20PM |

| P3–P4 | .E..LD | WP25PM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WU20PM |

| P5–P6 | .E..LD | WP25PM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| M1–M2 | .E..LD | WP25PM | .S..GD | WP25PM | .S..HD | WP25PM | .S..MM | WU20PM |

| M3 | .E..LD | WP35CM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| K1–K2 | .E..LD | TN6520 | .S..GD | WK15CM | .S..HD | WK15CM | .S..MM | WK15CM |

| K3 | .E..LD | WP35CM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| N1–N2 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | ||

| N3 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | ||

| S1–S2 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

| S3 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

| S4 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

Empfohlene Startwerte für Vorschübe [mm]

| Light

|

General

|

Heavy

|

| M1200 15º Lead • Recommended Starting Feeds [mm/th] | ||||||

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | |||||

| 30% | 40

|

|||||

| L | M | H | L | M | H | |

| .F..LDJ | 0,22 | 0,42 | 0,83 | 0,21 | 0,38 | 0,76 |

| .E..LD | 0,22 | 0,64 | 1,28 | 0,21 | 0,59 | 1,17 |

| .S..GD | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| .S..HD | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| .S..Ceramic | – | – | – | – | – | – |

| .S..MM | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||

| Light

|

General

|

Heavy

|

| M1200 15º Lead • Recommended Starting Feeds [IPT] | ||||||

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | |||||

| 30% | 40

|

|||||

| L | M | H | L | M | H | |

| .F..LDJ | 0.008 | 0.017 | 0.034 | 0.008 | 0.015 | 0.031 |

| .E..LD | 0.008 | 0.025 | 0.051 | 0.008 | 0.023 | 0.046 |

| .S..GD | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| .S..HD | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| .S..Ceramic | – | – | – | – | – | – |

| .S..MM | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||

Empfohlene Start-Schnittgeschwindigkeiten [m/min]

| M1200 • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Grade | THM-U | TN6501 | TN6510 | TN6520 | TN6525 | TN6540 | WK15CM | |||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | |

| K | 1 | – | – | – | – | – | – | 480 | 350 | 260 | 450 | 320 | 230 | 275 | 245 | 220 | 220 | 205 | 180 | 505 | 460 | 410 |

| 2 | – | – | – | – | – | – | 420 | 280 | 205 | 390 | 250 | 190 | 215 | 190 | 180 | 175 | 155 | 140 | 400 | 355 | 330 | |

| 3 | – | – | – | – | – | – | 335 | 260 | 200 | 300 | 230 | 160 | 180 | 160 | 145 | 155 | 145 | 125 | 335 | 300 | 275 | |

| N | 1 | 2400 | 1440 | 1200 | 2400 | 1440 | 1200 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1640 | 980 | 800 | 1640 | 980 | 800 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 960 | 600 | 480 | 960 | 600 | 480 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Grade | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WK25YM | |||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 395 | 340 | 325 | 545 | 475 | 445 | 355 | 310 | 295 | – | – | – | – | – | – | 330 | 290 | 270 | – | – | – |

| 2 | 330 | 290 | 240 | 335 | 305 | 275 | 300 | 260 | 215 | – | – | – | – | – | – | 275 | 250 | 200 | – | – | – | |

| 3 | 305 | 260 | 210 | 305 | 275 | 245 | 275 | 235 | 190 | – | – | – | – | – | – | 255 | 220 | 175 | – | – | – | |

| 4 | 270 | 220 | 180 | 230 | 210 | 190 | 245 | 205 | 160 | – | – | – | – | – | – | 225 | 190 | 150 | – | – | – | |

| 5 | 220 | 205 | 180 | 310 | 275 | 250 | 205 | 185 | 160 | – | – | – | 205 | 175 | 145 | 185 | 175 | 150 | – | – | – | |

| 6 | 200 | 150 | 120 | 190 | 160 | 130 | 180 | 140 | 110 | – | – | – | 180 | 130 | 95 | 165 | 130 | 100 | – | – | – | |

| M | 1 | 245 | 215 | 200 | 245 | 220 | 185 | 235 | 205 | 185 | 270 | 240 | 220 | 250 | 205 | 170 | 205 | 180 | 165 | – | – | – |

| 2 | 220 | 190 | 155 | 220 | 190 | 170 | 210 | 180 | 150 | 245 | 215 | 175 | 215 | 175 | 145 | 185 | 160 | 130 | – | – | – | |

| 3 | 170 | 145 | 115 | 175 | 155 | 140 | 155 | 140 | 110 | 185 | 160 | 125 | 175 | 130 | 100 | 140 | 120 | 95 | – | – | – | |

| K | 1 | 275 | 245 | 220 | 355 | 320 | 290 | – | – | – | – | – | – | – | – | – | 250 | 220 | 185 | 965 | 880 | 780 |

| 2 | 215 | 190 | 180 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | 200 | 180 | 150 | 765 | 685 | 635 | |

| 3 | 180 | 160 | 145 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | 180 | 150 | 120 | 645 | 570 | 525 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | |

| S | 1 | 50 | 40 | 30 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | 40 | 35 | 25 | – | – | – |

| 2 | 50 | 40 | 30 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | 40 | 35 | 25 | – | – | – | |

| 3 | 60 | 50 | 30 | – | – | – | 60 | 50 | 35 | 65 | 55 | 35 | 60 | 50 | 30 | 50 | 40 | 25 | – | – | – | |

| 4 | 85 | 60 | 40 | 80 | 60 | 40 | 80 | 60 | 40 | 100 | 70 | 50 | 70 | 60 | 35 | 70 | 50 | 35 | – | – | – | |

| H | 1 | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Grade | THM-U | TN6501 | TN6510 | TN6520 | TN6525 | TN6540 | WK15CM | |||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | – | – | – | |

| K | 1 | – | – | – | – | – | – | 1570 | 1140 | 845 | 1475 | 1045 | 750 | 905 | 805 | 725 | 725 | 670 | 590 | 1655 | 1520 | 1340 |

| 2 | – | – | – | – | – | – | 1380 | 925 | 670 | 1280 | 830 | 630 | 710 | 630 | 590 | 570 | 510 | 450 | 1320 | 1165 | 1080 | |

| 3 | – | – | – | – | – | – | 1105 | 845 | 650 | 985 | 750 | 535 | 590 | 535 | 475 | 510 | 475 | 415 | 1105 | 985 | 905 | |

| N | 1 | 7870 | 4720 | 3935 | 7870 | 4720 | 3935 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 5370 | 3210 | 2615 | 5370 | 3210 | 2615 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 3150 | 1970 | 1570 | 3150 | 1970 | 1570 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 155 | 120 | 95 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 140 | 95 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 200 | 95 | 80 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Grade | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WK25YM | |||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 970 | 855 | 805 | – | – | – | – | – | – | 1080 | 950 | 890 | – | – | – |

| 2 | 1080 | 940 | 785 | 1105 | 1000 | 905 | 820 | 705 | 590 | – | – | – | – | – | – | 900 | 820 | 660 | – | – | – | |

| 3 | 1000 | 845 | 690 | 1000 | 905 | 805 | 755 | 640 | 525 | – | – | – | – | – | – | 840 | 720 | 570 | – | – | – | |

| 4 | 890 | 725 | 590 | 750 | 690 | 630 | 675 | 560 | 445 | – | – | – | – | – | – | 740 | 620 | 490 | – | – | – | |

| 5 | 725 | 670 | 590 | 1025 | 905 | 830 | 560 | 510 | 445 | – | – | – | 560 | 475 | 395 | 610 | 570 | 490 | – | – | – | |

| 6 | 650 | 490 | 395 | 630 | 535 | 430 | 490 | 375 | 295 | – | – | – | 490 | 360 | 260 | 540 | 430 | 330 | – | – | – | |

| M | 1 | 805 | 710 | 650 | 805 | 725 | 610 | 640 | 560 | 510 | 890 | 785 | 725 | 690 | 560 | 460 | 670 | 590 | 540 | – | – | – |

| 2 | 725 | 630 | 510 | 725 | 630 | 550 | 575 | 490 | 410 | 805 | 710 | 570 | 590 | 475 | 395 | 610 | 520 | 430 | – | – | – | |

| 3 | 550 | 475 | 370 | 570 | 510 | 450 | 425 | 375 | 295 | 610 | 535 | 415 | 475 | 360 | 280 | 460 | 390 | 310 | – | – | – | |

| K | 1 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – | 820 | 720 | 610 | 3170 | 2880 | 2560 |

| 2 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | 660 | 590 | 490 | 2510 | 2240 | 2090 | |

| 3 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | 590 | 490 | 390 | 2110 | 1870 | 1720 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1310 | 1150 | 980 | – | – | – | |

| S | 1 | 155 | 140 | 95 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | 130 | 110 | 80 | – | – | – |

| 2 | 155 | 140 | 95 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | 130 | 110 | 80 | – | – | – | |

| 3 | 200 | 155 | 95 | – | – | – | – | – | – | 215 | 180 | 120 | 165 | 130 | 80 | 160 | 130 | 80 | – | – | – | |

| 4 | 275 | 200 | 140 | 260 | 200 | 130 | – | – | – | 335 | 235 | 155 | 195 | 165 | 100 | 230 | 160 | 110 | – | – | – | |

| H | 1 | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 260 | 230 | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||