Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

WIDIA steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Leistungsstarke Werkzeuglösungen jetzt im Angebot.

Bestellen Sie jetzt!

WIDIA steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

- M680-16 • Weldon® Schaftfräser • metrisch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

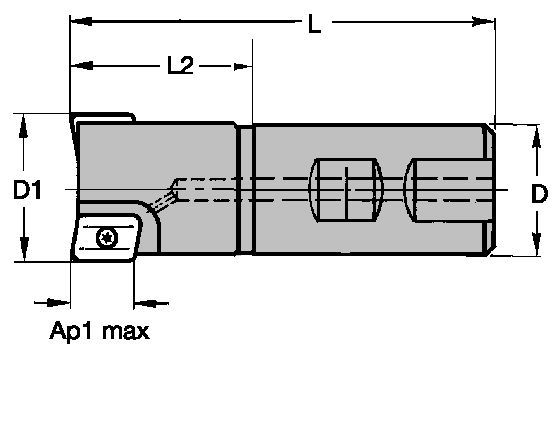

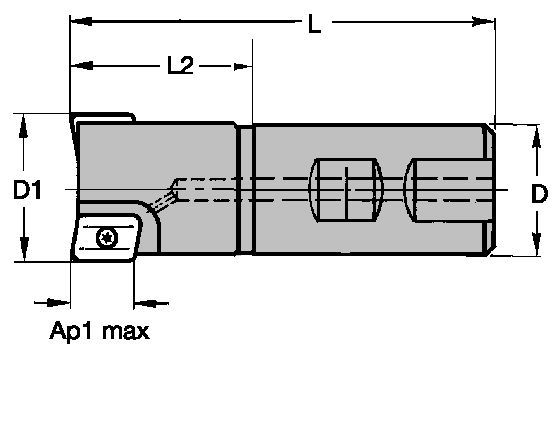

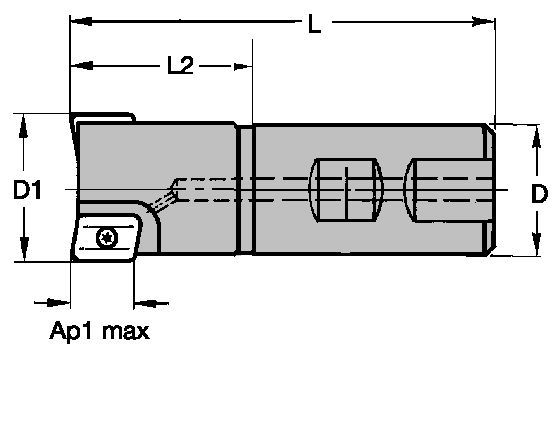

M680-16 • Weldon® Schaftfräser • metrisch

Weldon®-Schaftfräser • Metrisch

Features and benefits

- Universal-Eckfräser

- Umfangreiche Auswahl an Schneidstoffsorten und Geometrien.

- Stabile Wendeschneidplatte mit einer hohen Zuverlässigkeit

Uses and application

Planfräsen

Nutenfräsen: Ebene Stirnfläche

Fräsen – Innere Kühlmittelzuführung

Zylinderschaft – Weldon, 2 Spannflächen

Side Milling/Shoulder Milling: Square End

Auswahlhilfe für Wendeschneidplatten

| Material

|

Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | XPHT-GE | WP40PM | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P3–P4 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P5–P6 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| M1–M2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| M3 | XPHT-GE | TN7535 | XPHT.. | WP40PM | XPHT-MR | TN7535 |

| K1–K2 | XPHT-GE | TN6510 | XPHT.. | TN6520 | XPHT-MR | WK15CM |

| K3 | XPHT-GE | TN6510 | XPHT.. | TN7535 | XPHT-MR | WK15CM |

| N1–N2 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| N3 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| S1–S2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S3 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S4 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| H1 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

Empfohlene Startwerte für Vorschübe [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| XPHT-ALP | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | XPHT-ALP |

| XPHT-GE | 0,19 | 0,47 | 0,70 | 0,14 | 0,34 | 0,50 | 0,11 | 0,26 | 0,38 | 0,09 | 0,22 | 0,33 | 0,08 | 0,20 | 0,30 | XPHT-GE |

| XPHT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPHT.. |

| XPNT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPNT.. |

| XPHT-MR | 0,23 | 0,59 | 0,92 | 0,17 | 0,43 | 0,66 | 0,13 | 0,32 | 0,50 | 0,11 | 0,28 | 0,43 | 0,10 | 0,25 | 0,40 | XPHT-MR |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .F..ALP | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .F..ALP |

| .E..AL | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .E..AL |

| .E..GE | .008 | .018 | .027 | .005 | .013 | .020 | .004 | .010 | .015 | .004 | .009 | .013 | .003 | .008 | .012 | .E..GE |

| Light

|

General

|

Heavy

|

Empfohlene Start-Schnittgeschwindigkeiten [m/min]

| Material Group | THR | THM-U | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | TN6540 | |||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 |

| 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | |

| K | 1 | 150 | 135 | 120 | 190 | 170 | 150 | – | – | – | – | – | – | 400 | 290 | 215 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 |

| 2 | 185 | 140 | 120 | – | – | – | – | – | – | – | – | – | 350 | 235 | 170 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | |

| 3 | 105 | 75 | 50 | – | – | – | – | – | – | – | – | – | 280 | 215 | 165 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | |

| N | 1 | 900 | 600 | 500 | 2000 | 1200 | 1000 | 2000 | 1200 | 1000 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | 1365 | 815 | 665 | 1365 | 815 | 665 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | 800 | 500 | 400 | 800 | 500 | 400 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 25 | 20 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 30 | 25 |

| 2 | 25 | 20 | 15 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 20 | 15 | 10 | |

| 3 | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 35 | 25 | |

| 4 | 35 | 25 | 18 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 25 | 20 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | TTM08 | WK15PM | WP35CM | WU20PM | TTI25 | THM | WK15CM | WP40PM | WS30PM | |||||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – |

| 1 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | 330 | 290 | 270 | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – | |

| 2 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | 275 | 250 | 200 | 260 | 210 | 180 | – | – | – | – | – | – | 250 | 215 | 180 | – | – | – | |

| 3 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | 255 | 220 | 175 | 260 | 210 | 180 | – | – | – | – | – | – | 230 | 195 | 160 | – | – | – | |

| 4 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | 225 | 190 | 150 | 220 | 180 | 150 | – | – | – | – | – | – | 205 | 170 | 135 | – | – | – | |

| 5 | – | – | – | – | – | – | 260 | 230 | 210 | 185 | 175 | 150 | 265 | 195 | 165 | – | – | – | – | – | – | 170 | 155 | 135 | – | – | – | |

| 6 | – | – | – | – | – | – | 160 | 135 | 110 | 165 | 130 | 100 | 120 | 90 | 75 | – | – | – | – | – | – | 150 | 115 | 90 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 185 | 155 | 205 | 180 | 165 | 400 | 260 | 180 | – | – | – | – | – | – | 195 | 170 | 155 | 225 | 200 | 185 |

| 2 | – | – | – | – | – | – | 185 | 160 | 140 | 185 | 160 | 130 | 270 | 170 | 120 | – | – | – | – | – | – | 175 | 150 | 125 | 205 | 180 | 145 | |

| 3 | – | – | – | – | – | – | 145 | 130 | 115 | 140 | 120 | 95 | 265 | 175 | 120 | – | – | – | – | – | – | 130 | 115 | 90 | 155 | 135 | 105 | |

| K | 1 | – | – | – | 400 | 290 | 215 | 295 | 265 | 240 | 250 | 220 | 185 | 185 | 155 | 130 | – | – | – | 420 | 385 | 340 | – | – | – | – | – | – |

| 2 | – | – | – | 350 | 235 | 170 | 235 | 210 | 190 | 200 | 180 | 150 | 150 | 120 | 105 | – | – | – | 335 | 295 | 275 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 165 | 195 | 175 | 160 | 180 | 150 | 120 | 120 | 105 | 85 | – | – | – | 280 | 250 | 230 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | 560 | 485 | 420 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 66 | 50 | 33 | 70 | 50 | 35 | – | – | – | – | – | – | – | – | – | 65 | 50 | 35 | 85 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | THM | THM-U | THR | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1345 | 1050 | 920 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1050 | 820 | 705 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 920 | 705 | 605 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 560 | 475 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1015 | 770 | 640 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 525 | 425 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 625 | 395 | 260 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 165 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 410 | 260 | 180 | |

| K | 1 | 390 | 295 | 245 | 620 | 555 | 490 | 490 | 440 | 390 | – | – | – | – | – | – | 1575 | 1150 | 835 | 1475 | 1050 | 755 | – | – | – |

| 2 | 410 | 325 | 225 | – | – | – | 605 | 455 | 390 | – | – | – | – | – | – | 1380 | 920 | 670 | 1280 | 820 | 625 | – | – | – | |

| 3 | 425 | 310 | 195 | – | – | – | 340 | 245 | 160 | – | – | – | – | – | – | 1100 | 855 | 655 | 985 | 740 | 525 | – | – | – | |

| N | 1 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 5245 | 3115 | 2620 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 3605 | 2180 | 1800 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 2130 | 1310 | 980 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 110 | 80 | 65 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 65 | 45 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 160 | 130 | 95 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 110 | 80 | 55 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | TN6540 | TTI25 | TTM08 | WK15CM | WK15PM | WP35CM | WP40PM | WS30PM | WU20PM | |||||||||||||||||||

| P | 1 | 1180 | 920 | 785 | 1180 | 985 | 820 | 750 | 655 | 620 | – | – | – | – | – | – | 1490 | 1295 | 1210 | 970 | 855 | 805 | 1215 | 1050 | 985 | 1080 | 950 | 885 |

| 2 | 820 | 625 | 540 | 855 | 690 | 590 | 635 | 555 | 455 | – | – | – | – | – | – | 915 | 835 | 750 | 820 | 705 | 590 | 1000 | 885 | 720 | 900 | 820 | 655 | |

| 3 | 705 | 540 | 460 | 855 | 690 | 590 | 590 | 490 | 410 | – | – | – | – | – | – | 835 | 750 | 670 | 755 | 640 | 525 | 935 | 785 | 640 | 835 | 720 | 570 | |

| 4 | 590 | 425 | 360 | 720 | 590 | 490 | 520 | 425 | 340 | – | – | – | – | – | – | 620 | 570 | 520 | 670 | 560 | 445 | 820 | 670 | 540 | 735 | 620 | 490 | |

| 5 | 785 | 590 | 490 | 870 | 640 | 540 | – | – | – | – | – | – | – | – | – | 850 | 750 | 685 | 560 | 510 | 445 | 670 | 625 | 540 | 605 | 570 | 490 | |

| 6 | 525 | 395 | 330 | 395 | 295 | 245 | – | – | – | – | – | – | – | – | – | 520 | 440 | 360 | 490 | 375 | 295 | 605 | 460 | 360 | 540 | 425 | 325 | |

| M | 1 | 425 | 260 | 195 | 1310 | 855 | 590 | – | – | – | – | – | – | – | – | – | 670 | 605 | 505 | 640 | 560 | 510 | 740 | 655 | 605 | 670 | 590 | 540 |

| 2 | 260 | 165 | 130 | 885 | 560 | 395 | – | – | – | – | – | – | – | – | – | 605 | 520 | 455 | 575 | 490 | 410 | 670 | 590 | 475 | 605 | 520 | 425 | |

| 3 | 280 | 165 | 130 | 870 | 575 | 395 | – | – | – | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 445 | 345 | 455 | 390 | 310 | |

| K | 1 | – | – | – | 605 | 510 | 425 | – | – | – | 1380 | 1265 | 1115 | 1310 | 950 | 705 | 965 | 865 | 785 | – | – | – | 835 | 740 | 640 | 820 | 720 | 605 |

| 2 | – | – | – | 490 | 395 | 345 | – | – | – | 1100 | 970 | 900 | 1145 | 770 | 555 | 770 | 685 | 620 | – | – | – | 655 | 590 | 540 | 655 | 590 | 490 | |

| 3 | – | – | – | 395 | 345 | 280 | – | – | – | 920 | 820 | 755 | 915 | 800 | 540 | 635 | 570 | 520 | – | – | – | 540 | 490 | 445 | 590 | 490 | 390 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1310 | 1145 | 980 | |

| S | 1 | 150 | 115 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 |

| 2 | 80 | 65 | 35 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 | |

| 3 | 230 | 130 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 160 | 130 | 80 | |

| 4 | 195 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 215 | 160 | 105 | 215 | 165 | 115 | 280 | 195 | 130 | 225 | 160 | 110 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 445 | 330 | 245 | 360 | 260 | 225 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |