Product Similar To :

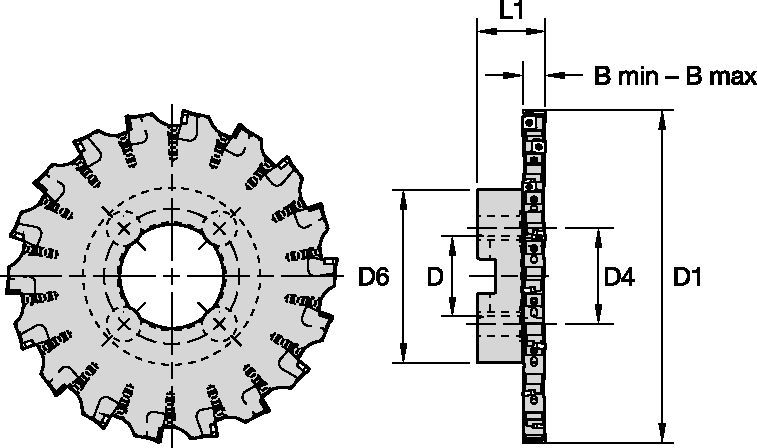

M900 • Shell Mount • 9mm

Shell Mount • 9mm

Material Number2003897

ISO Catalog ID12399110800ANSI Catalog ID12399110800

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Slotting: Side

Slotting: Side with AE/AP dimensions

Side Milling/Shoulder Milling: Square End with AE/AP dimensions

Side Milling/Shoulder Milling: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

| Material Number | 2003897 |

| ISO Catalog ID | 12399110800 |

| ANSI Catalog ID | 12399110800 |

| Grade | W |

| [D1] Effective Cutting Diameter | 200 mm |

| [D1] Effective Cutting Diameter | 7.874 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.5748 in |

| [D4] Bolt Circle 4 | 66.7 mm |

| [D4] Bolt Circle 3 | 2.626 in |

| [D6] Hub Diameter | 90 mm |

| [D6] Hub Diameter | 3.5433 in |

| [BM] Cutting Width Minimum | 12 mm |

| [BM] Cutting Width Minimum | 0.4724 in |

| [BMAX] Cutting Width Maximum | 14 mm |

| [BMAX] Cutting Width Maximum | 0.5512 in |

| [L1] Gage Length | 44 mm |

| [L1] Gage Length | 1.7323 in |

| Number of Inserts | 12 |

| Max RPM | 5040 |

| Coolant Supply | N |

| Weight Kilograms | 3 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Slotting: Side

Slotting: Side with AE/AP dimensions

Side Milling/Shoulder Milling: Square End with AE/AP dimensions

Side Milling/Shoulder Milling: Square End

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

M900 Cutting Data • MDH.. • P Coating

| TN7525 | TN7535 | TN450 | TTM | TTR | |||||||||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||||||||||||||

| M900 | MDHX09T308 | – | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material | vc (m/min) | ||||||||||||||||

| P | 1 | 330 | 250 | 210 | 280 | 215 | 185 | 250 | 215 | 200 | 170 | 150 | 140 | 135 | 120 | 110 | |

| 2 | 250 | 195 | 170 | 190 | 150 | 130 | 180 | 150 | 140 | 120 | 100 | 90 | 95 | 80 | 70 | ||

| 3 | 210 | 160 | 145 | 160 | 120 | 110 | 150 | 130 | 120 | 100 | 80 | 70 | 80 | 65 | 55 | ||

| 4 | 215 | 170 | 145 | 165 | 130 | 110 | 160 | 140 | 130 | 110 | 85 | 80 | 90 | 70 | 65 | ||

| 5 | 185 | 130 | 115 | 140 | 100 | 85 | 130 | 110 | 100 | 85 | 70 | 60 | 70 | 55 | 50 | ||

| 6 | 240 | 185 | 150 | 185 | 140 | 115 | 180 | 150 | 140 | 120 | 100 | 90 | 95 | 80 | 70 | ||

| 7 | 185 | 145 | 120 | 140 | 110 | 90 | 140 | 120 | 110 | 90 | 80 | 70 | 70 | 65 | 55 | ||

| 8 | 160 | 120 | 105 | 120 | 90 | 80 | 120 | 100 | 90 | 80 | 60 | 55 | 65 | 50 | 45 | ||

| 9 | 145 | 105 | 90 | 110 | 80 | 70 | 100 | 70 | 60 | 70 | 50 | 40 | 55 | 40 | 30 | ||

| 10 | 185 | 145 | 130 | 140 | 110 | 100 | 160 | 135 | 120 | 110 | 85 | 80 | 90 | 70 | 65 | ||

| 11 | 120 | 95 | 80 | 90 | 70 | 60 | 100 | 70 | 55 | 70 | 50 | 40 | 55 | 40 | 30 | ||

| 12 | 235 | 175 | 150 | 180 | 135 | 115 | 170 | 150 | 140 | 115 | 90 | 85 | 90 | 70 | 70 | ||

| 13.1 | 205 | 145 | 120 | 155 | 110 | 90 | 140 | 120 | 110 | 100 | 80 | 70 | 80 | 65 | 55 | ||

| 13.2 | 100 | 70 | 60 | 80 | 55 | 45 | 70 | 60 | 55 | 50 | 40 | 35 | 40 | 30 | 30 | ||

M900 Cutting Data • MDH.. • M Coating

| TN7525 | TN7535 | TN450 | TTM | TTR | |||||||||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||||||||||||||

| M900 | MDHX09T308 | – | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material | vc (m/min) | ||||||||||||||||

| M | 14.1 | 240 | 200 | 160 | 220 | 180 | 160 | 150 | 90 | 80 | 120 | 80 | 70 | 100 | 70 | 50 | |

| 14.2 | 190 | 160 | 135 | 180 | 150 | 135 | 130 | 80 | 70 | 90 | 60 | 55 | 80 | 50 | 40 | ||

| 14.3 | 140 | 120 | 100 | 130 | 110 | 100 | 100 | 65 | 55 | 65 | 50 | 40 | 60 | 40 | 30 | ||

| 14.4 | 120 | 100 | 80 | 110 | 90 | 80 | 75 | 45 | 40 | 60 | 40 | 35 | 50 | 35 | 25 | ||

M900 Cutting Data • MDH.. • K Coating

| TN5515 | THM | |||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | |||||

| M900 | MDHX09T308 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| M900 | MDHW120408 | – | 0,10 | 0,12 | 0,14 | 0,10 | 0,12 | 0,14 |

| Material | vc (m/min) | |||||||

| K | 15 | 295 | 215 | 185 | 135 | 100 | 85 | |

| 16 | 225 | 170 | 145 | 100 | 80 | 70 | ||

| 17 | 250 | 185 | 150 | 120 | 90 | 75 | ||

| 18 | 185 | 110 | 80 | 85 | 60 | 40 | ||

| 19 | 255 | 150 | 120 | 120 | 75 | 50 | ||

| 20 | 195 | 125 | 90 | 95 | 60 | 40 | ||

M900 Cutting Data • MDH.. • N Coating

| THM | |||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||

| M900 | MDHX09T308 | – | 0,08 | 0,10 | 0,12 |

| M900 | MDHW120408 | – | 0,10 | 0,12 | 0,14 |

| Material | vc (m/min) | ||||

| N | 21 | 1000 | 750 | 600 | |

| 22 | 500 | 360 | 300 | ||

| 23 | 1000 | 750 | 600 | ||

| 24 | 800 | 600 | 500 | ||

| 25 | 500 | 350 | 250 | ||

| 27 | 400 | 250 | 180 | ||

| 28 | 300 | 180 | 120 | ||

M900 Cutting Data • MDH.. • S Coating

| TN5515 | THM | |||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | |||||

| M900 | MDHX09T308 | – | 0,05 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,07 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material | vc (m/min) | |||||||

| S | 31 | 48 | 36 | 30 | 36 | 28 | 24 | |

| 32 | 40 | 30 | 25 | 30 | 23 | 20 | ||

| 33 | 32 | 24 | 20 | 24 | 19 | 16 | ||

| 34 | 26 | 19 | 14 | 20 | 15 | 12 | ||

| 35 | 26 | 19 | 14 | 20 | 15 | 12 | ||

| 36 | – | – | – | 80 | 50 | 40 | ||

| 37 | – | – | – | 70 | 46 | 35 | ||

I have read and accepted the Terms & Conditions of use