Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Herramientas de alto rendimiento ya a la venta.

Compre ahora.

WIDIA a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Produtos

- /

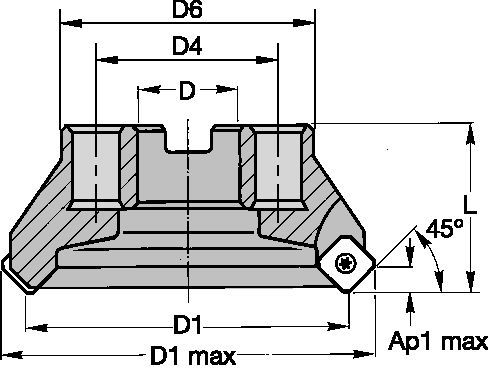

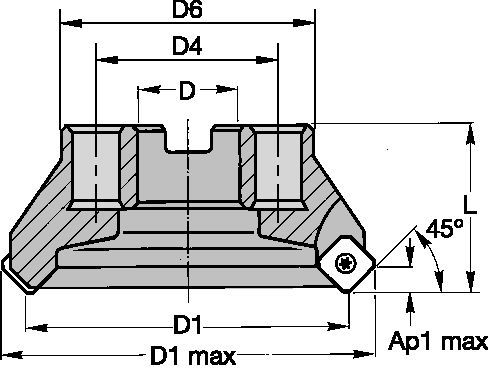

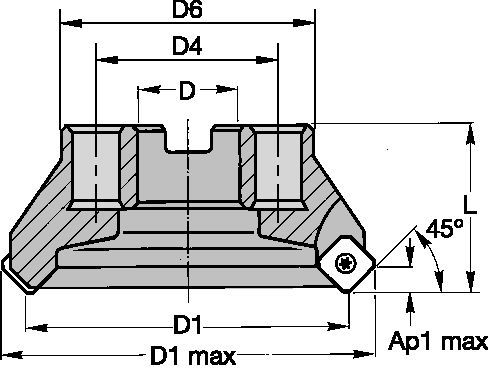

- M660 • Fresas de plato SN1205.. • Sistema métrico

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

M660 • Fresas de plato SN1205.. • Sistema métrico

Fresas de plato • SN1205..

Features and benefits

- Cuatro filos de corte.

- Cuerpo de herramienta con sólido diseño.

- Excelente evacuación de virutas.

Uses and application

Planeado

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Guía para la selección de plaquitas

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | …20 | TN6540 | …31 | WP40PM | …31 | WP40PM |

| P3–P4 | …20 | WP35CM | …31 | WP35CM | …31 | WP35CM |

| P5–P6 | …20 | WP35CM | …31 | WP35CM | …31 | WP35CM |

| M1–M2 | …20 | TN6540 | …31 | WP25PM | …31 | WP25PM |

| M3 | ...20 | WP35CM | …31 | WP35CM | …31 | WP35CM |

| K1–K2 | ...21 | WK15CM | …31 | WK15CM | …31 | WK15CM |

| K3 | ...21 | WK15CM | …31 | WP35CM | …31 | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ...20 | TN6540 | …31 | WP25PM | …31 | WP25PM |

| S3 | – | – | – | – | – | – |

| S4 | ...20 | TN6540 | …31 | WP40PM | …31 | WP40PM |

| H1 | – | – | – | – | – | – |

Avances iniciales recomendados [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| ...20 | 0,17 | 0,66 | 1,19 | 0,12 | 0,47 | 0,86 | 0,09 | 0,35 | 0,64 | 0,08 | 0,31 | 0,56 | 0,07 | 0,28 | 0,51 | ...20 |

| …21 | 0,24 | 0,74 | 1,25 | 0,18 | 0,53 | 0,89 | 0,13 | 0,40 | 0,66 | 0,12 | 0,35 | 0,58 | 0,11 | 0,32 | 0,53 | …21 |

| …31 | 0,26 | 0,76 | 1,28 | 0,19 | 0,55 | 0,91 | 0,14 | 0,41 | 0,68 | 0,12 | 0,36 | 0,59 | 0,11 | 0,33 | 0,54 | …31 |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| ...20 | .007 | .026 | .047 | .005 | .018 | .033 | .004 | .014 | .025 | .003 | .012 | .022 | .003 | .011 | .020 | ...20 |

| …21 | .010 | .029 | .049 | .007 | .021 | .035 | .005 | .016 | .026 | .005 | .014 | .023 | .004 | .013 | .021 | …21 |

| …31 | .010 | .030 | .050 | .007 | .022 | .036 | .006 | .016 | .027 | .005 | .014 | .023 | .004 | .013 | .021 | …31 |

| Light

|

General

|

Heavy

|

Velocidades iniciales recomendadas [m/min]

| Material Group | TN6525 | TN6540 | TTM08 | WP25PM | WP35CM | |||||||||||

| P | 1 | 410 | 320 | 280 | 360 | 280 | 240 | 230 | 200 | 190 | 395 | 340 | 325 | 455 | 395 | 370 |

| 2 | 320 | 250 | 215 | 250 | 190 | 170 | 195 | 170 | 140 | 330 | 290 | 240 | 280 | 255 | 230 | |

| 3 | 280 | 215 | 185 | 215 | 170 | 140 | 180 | 150 | 125 | 305 | 260 | 210 | 255 | 230 | 205 | |

| 4 | 235 | 170 | 145 | 180 | 130 | 110 | 160 | 130 | 105 | 270 | 220 | 180 | 190 | 175 | 160 | |

| 5 | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | 220 | 205 | 180 | 260 | 230 | 210 | |

| 6 | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | 200 | 150 | 120 | 160 | 135 | 110 | |

| M | 1 | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – | 245 | 215 | 200 | 205 | 185 | 155 |

| 2 | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | 220 | 190 | 155 | 185 | 160 | 140 | |

| 3 | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | 170 | 145 | 115 | 145 | 130 | 115 | |

| K | 1 | 275 | 245 | 220 | 220 | 205 | 180 | – | – | – | 275 | 245 | 220 | 295 | 265 | 240 |

| 2 | 215 | 190 | 180 | 175 | 155 | 140 | – | – | – | 215 | 190 | 180 | 235 | 210 | 190 | |

| 3 | 180 | 160 | 145 | 155 | 145 | 125 | – | – | – | 180 | 160 | 145 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 50 | 35 | 30 | – | – | – | 50 | 40 | 30 | – | – | – |

| 2 | – | – | – | 25 | 20 | 10 | – | – | – | 50 | 40 | 30 | – | – | – | |

| 3 | – | – | – | 70 | 40 | 30 | – | – | – | 60 | 50 | 30 | – | – | – | |

| 4 | – | – | – | 60 | 30 | 25 | – | – | – | 85 | 60 | 40 | 66 | 50 | 33 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | WK15CM | WP40PM | TTI25 | THM | |||||||||

| P | 1 | – | – | – | 355 | 310 | 295 | 430 | 360 | 300 | – | – | – |

| 2 | – | – | – | 300 | 260 | 215 | 310 | 250 | 215 | – | – | – | |

| 3 | – | – | – | 275 | 235 | 190 | 310 | 250 | 215 | – | – | – | |

| 4 | – | – | – | 245 | 205 | 160 | 265 | 215 | 180 | – | – | – | |

| 5 | – | – | – | 205 | 185 | 160 | 320 | 235 | 200 | – | – | – | |

| 6 | – | – | – | 180 | 140 | 110 | 145 | 110 | 90 | – | – | – | |

| M | 1 | – | – | – | 235 | 205 | 185 | 480 | 310 | 215 | – | – | – |

| 2 | – | – | – | 210 | 180 | 150 | 325 | 205 | 145 | – | – | – | |

| 3 | – | – | – | 155 | 140 | 110 | 320 | 210 | 145 | – | – | – | |

| K | 1 | 505 | 460 | 410 | – | – | – | 220 | 185 | 155 | 145 | 110 | 90 |

| 2 | 400 | 355 | 330 | – | – | – | 180 | 145 | 125 | 150 | 120 | 85 | |

| 3 | 335 | 300 | 275 | – | – | – | 145 | 125 | 100 | 155 | 115 | 70 | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1080 | 720 | 600 |

| 2 | – | – | – | – | – | – | – | – | – | 820 | 560 | 460 | |

| 3 | – | – | – | – | – | – | – | – | – | 540 | 335 | 240 | |

| S | 1 | – | – | – | 50 | 40 | 35 | – | – | – | – | – | – |

| 2 | – | – | – | 50 | 40 | 35 | – | – | – | – | – | – | |

| 3 | – | – | – | 60 | 50 | 35 | – | – | – | – | – | – | |

| 4 | – | – | – | 80 | 60 | 40 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | TN6525 | TN6540 | TN7525 | TN7535 | WK15CM | |||||||||||

| P | 1 | 1340 | 1045 | 925 | 1180 | 925 | 785 | 1340 | 1025 | 925 | 1790 | 1555 | 1460 | – | – | – |

| 2 | 1045 | 830 | 710 | 830 | 630 | 550 | 1025 | 830 | 710 | 1105 | 1000 | 905 | – | – | – | |

| 3 | 925 | 710 | 610 | 710 | 550 | 450 | 925 | 710 | 610 | 1000 | 905 | 805 | – | – | – | |

| 4 | 770 | 550 | 475 | 590 | 430 | 355 | 770 | 550 | 475 | 750 | 690 | 630 | – | – | – | |

| 5 | 1025 | 770 | 650 | 785 | 590 | 490 | 1025 | 770 | 650 | 1025 | 905 | 830 | – | – | – | |

| 6 | 670 | 535 | 430 | 535 | 395 | 335 | 670 | 535 | 430 | 630 | 535 | 430 | – | – | – | |

| M | 1 | 630 | 395 | 260 | 430 | 260 | 200 | 805 | 725 | 610 | 805 | 725 | 610 | – | – | – |

| 2 | 395 | 260 | 155 | 260 | 155 | 140 | 725 | 630 | 550 | 725 | 630 | 550 | – | – | – | |

| 3 | 415 | 260 | 180 | 275 | 155 | 140 | 570 | 510 | 450 | 570 | 510 | 450 | – | – | – | |

| K | 1 | 905 | 805 | 725 | 725 | 670 | 590 | 1240 | 925 | 785 | 1165 | 1045 | 940 | 1655 | 1520 | 1340 |

| 2 | 710 | 630 | 590 | 570 | 510 | 450 | 1060 | 785 | 650 | 925 | 830 | 750 | 1320 | 1165 | 1080 | |

| 3 | 590 | 535 | 475 | 510 | 475 | 415 | 785 | 650 | 550 | 770 | 690 | 630 | 1105 | 985 | 905 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 155 | 120 | 95 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 80 | 60 | 40 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 235 | 140 | 95 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | 200 | 95 | 80 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | WP40PM | TTI25 | THM | |||||||

| P | 1 | 1165 | 1025 | 965 | 1415 | 1180 | 985 | – | – | – |

| 2 | 985 | 845 | 710 | 1025 | 830 | 710 | – | – | – | |

| 3 | 905 | 770 | 630 | 1025 | 830 | 710 | – | – | – | |

| 4 | 805 | 670 | 535 | 865 | 710 | 590 | – | – | – | |

| 5 | 670 | 610 | 535 | 1045 | 770 | 650 | – | – | – | |

| 6 | 590 | 450 | 355 | 475 | 355 | 295 | – | – | – | |

| M | 1 | 770 | 670 | 610 | 1570 | 1025 | 710 | – | – | – |

| 2 | 690 | 590 | 490 | 1060 | 670 | 475 | – | – | – | |

| 3 | 510 | 450 | 355 | 1045 | 690 | 475 | – | – | – | |

| K | 1 | – | – | – | 725 | 610 | 510 | 475 | 355 | 295 |

| 2 | – | – | – | 590 | 475 | 415 | 490 | 395 | 275 | |

| 3 | – | – | – | 475 | 415 | 335 | 510 | 370 | 235 | |

| N | 1 | – | – | – | – | – | – | 3540 | 2365 | 1970 |

| 2 | – | – | – | – | – | – | 2695 | 1830 | 1520 | |

| 3 | – | – | – | – | – | – | 1770 | 1105 | 785 | |

| S | 1 | 155 | 140 | 120 | – | – | – | – | – | – |

| 2 | 155 | 140 | 120 | – | – | – | – | – | – | |

| 3 | 200 | 155 | 120 | – | – | – | – | – | – | |

| 4 | 260 | 200 | 140 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |