Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

WIDIA a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Produtos

- /

- M95 SN1203 IN SNHX

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

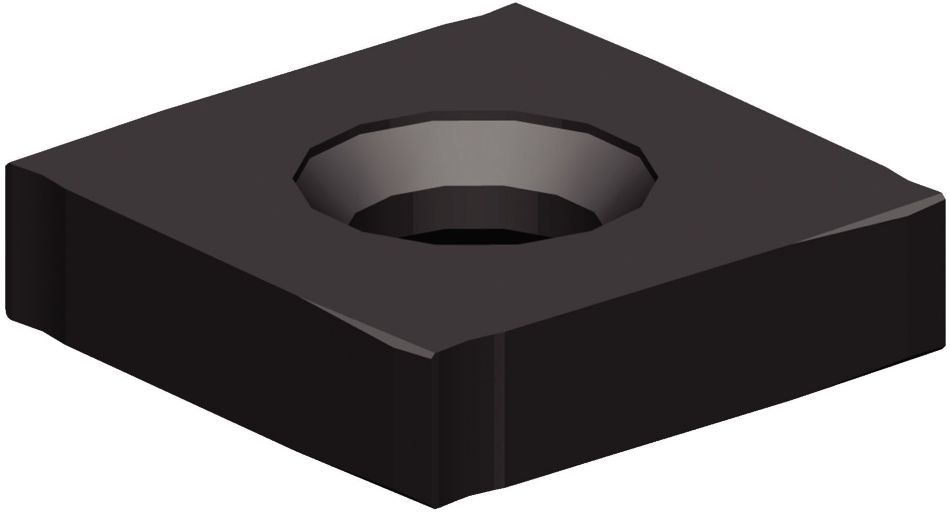

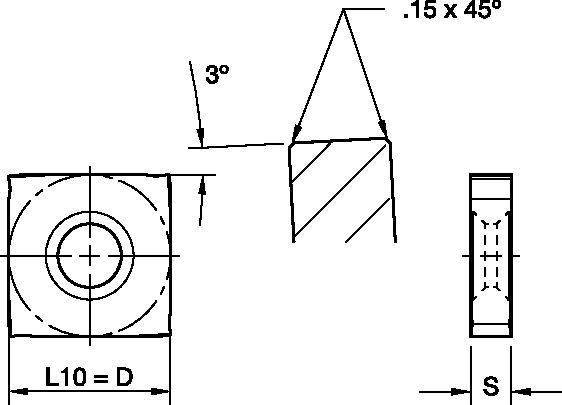

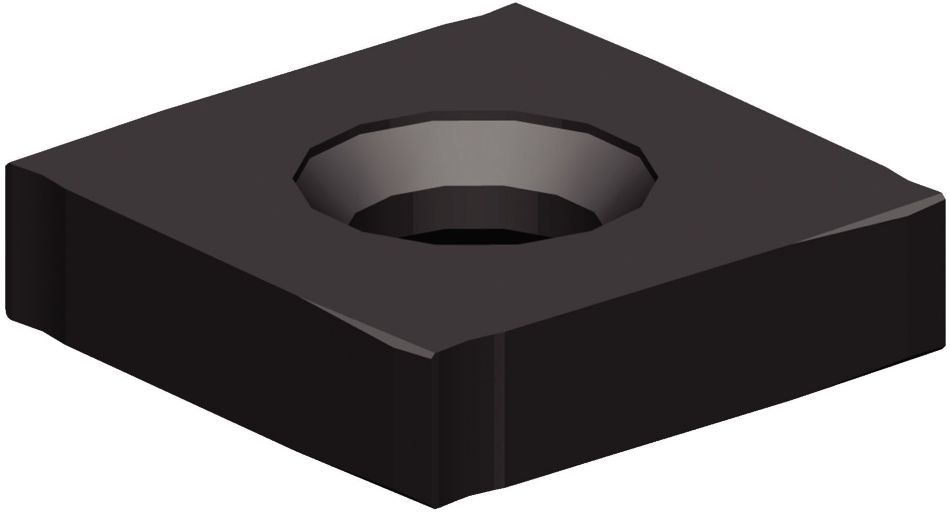

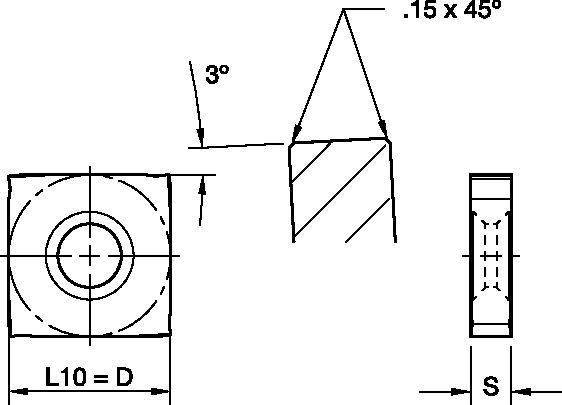

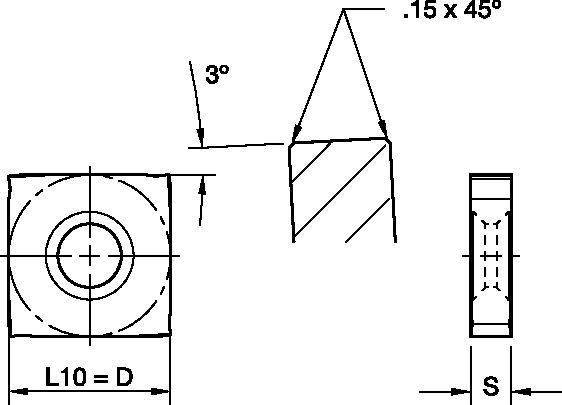

M95 SN1203 IN SNHX

Plaquitas

Guía para la selección de plaquitas

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | SNHX | WP40PM | SNHX | WP40PM | SNHX | WP40PM |

| P3–P4 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| P5–P6 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| M1–M2 | SNHX | WP40PM | SNHX | WP40PM | SNHX | WP40PM |

| M3 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| K1–K2 | SNHX | WK15CM | SNHX | WK15CM | SNHX | WK15CM |

| K3 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Avances iniciales recomendados [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| SNHX | 0,12 | 0,28 | 0,71 | 0,08 | 0,20 | 0,51 | 0,06 | 0,15 | 0,38 | 0,06 | 0,13 | 0,33 | 0,05 | 0,12 | 0,30 | SNHX |

| Light

|

General

|

Heavy

|

Velocidades iniciales recomendadas (m/min)

| Material Group | WK15CM | WP35CM | WP40PM | |||||||

| P | 0 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 |

| 1 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 | |

| 2 | – | – | – | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | – | – | – | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | – | – | – | 190 | 175 | 160 | 205 | 170 | 135 | |

| 5 | – | – | – | 260 | 230 | 210 | 170 | 155 | 135 | |

| 6 | – | – | – | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 420 | 385 | 340 | 295 | 265 | 240 | – | – | – |

| 2 | 335 | 295 | 275 | 235 | 210 | 190 | – | – | – | |

| 3 | 280 | 250 | 230 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | 66 | 50 | 33 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |