Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

WIDIA a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Produtos

- /

- RNGJ-ML

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

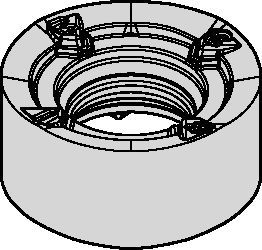

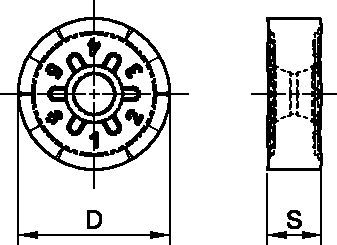

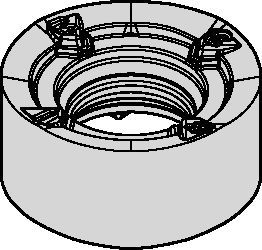

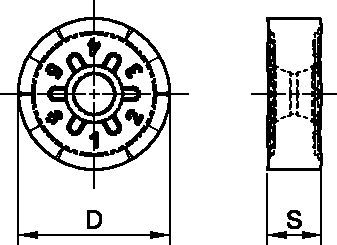

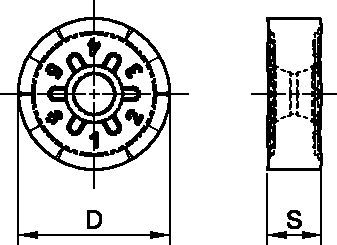

RNGJ-ML

1″ • Inserts • RNGJ85…

Features and benefits

- -ML geometry is the first choice for stainless steel and high-temp alloys.

Insert Selection Guide • M200™ Series • Large IC Expansion

| Light

|

General

|

Heavy

|

||||

| Material

|

Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..ML | WP25PM | .S..MM | WP40PM | .S..MM | WP40PM |

| P3–P4 | .E..ML | WP25PM | .S..MM | WP40PM | .S..MM | WP40PM |

| P5–P6 | .E..ML | WP25PM | .S..MM | WP35CM | .S..MM | WP35CM |

| M1–M2 | .E..ML | WP25PM | .S..MM | WU35PM | .S..MM | WU35PM |

| M3 | .E..ML | WP25PM | .S..MM | WU35PM | .S..MM | WU35PM |

| K1–K2 | – | – | .S..MM | WK15CM | – | – |

| K3 | – | – | .S..MM | WK15CM | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..ML | WP25PM | .S..MM | WU35PM | .S..MM | WU35PM |

| S3 | .E..ML | WP25PM | .S..MM | WU35PM | .S..MM | WU35PM |

| S4 | .E..ML | WP25PM | .S..MM | WU35PM | .S..MM | WU35PM |

| H1 | – | – | .S..MM | WP25PM | – | – |

| Light

|

General

|

Heavy

|

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 10% | 20% | 30% | 40% | 50–100% | Insert Geometry | ||||||||||

| .E..ML | .003 | .009 | .018 | .003 | .007 | .013 | .002 | .006 | .011 | .002 | .005 | .011 | .002 | .005 | .011 | .E..ML |

| .S..MM | .007 | .014 | .029 | .005 | .011 | .021 | .004 | .009 | .019 | .004 | .009 | .017 | .004 | .009 | .017 | .S..MM |

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 10% | 20% | 30% | 40% | 50–100% | Insert Geometry | ||||||||||

| .E..ML | .004 | .010 | .021 | .003 | .008 | .015 | .003 | .007 | .013 | .002 | .006 | .012 | .002 | .006 | .012 | .E..ML |

| .S..MM | .008 | .017 | .034 | .006 | .012 | .025 | .005 | .011 | .022 | .005 | .010 | .020 | .005 | .010 | .020 | .S..MM |

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 10% | 20% | 30% | 40% | 50–100% | Insert Geometry | ||||||||||

| .E..ML | .007 | .018 | .038 | .005 | .014 | .027 | .005 | .012 | .024 | .004 | .011 | .022 | .004 | .011 | .022 | .E..ML |

| .S..MM | .014 | .030 | .063 | .010 | .022 | .045 | .009 | .019 | .039 | .008 | .018 | .036 | .008 | .018 | .035 | .S..MM |

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 10% | 20% | 30% | 40% | 50–100% | Insert Geometry | ||||||||||

| .E..ML | .005 | .013 | .027 | .004 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | .003 | .008 | .016 | .E..ML |

| .S..MM | .010 | .022 | .045 | .008 | .016 | .033 | .007 | .014 | .028 | .006 | .013 | .026 | .006 | .013 | .026 | .S..MM |

Recommended Starting Speeds [SFM]

| Material Group | WK15CM | WP25PM | WU35PM | WP35CM | WP40PM | |||||||||||

| P | 1 | – | – | – | 1295 | 1120 | 1060 | 1025 | 905 | 845 | 1790 | 1555 | 1460 | 1165 | 1025 | 965 |

| 2 | – | – | – | 1080 | 940 | 785 | 865 | 750 | 630 | 1105 | 1000 | 905 | 985 | 845 | 710 | |

| 3 | – | – | – | 1000 | 845 | 690 | 785 | 670 | 550 | 1000 | 905 | 805 | 905 | 770 | 630 | |

| 4 | – | – | – | 890 | 725 | 590 | 710 | 590 | 475 | 750 | 690 | 630 | 805 | 670 | 535 | |

| 5 | – | – | – | 725 | 670 | 590 | 590 | 535 | 475 | 1025 | 905 | 830 | 670 | 610 | 535 | |

| 6 | – | – | – | 650 | 490 | 395 | 510 | 395 | 310 | 630 | 535 | 430 | 590 | 450 | 355 | |

| M | 1 | – | – | – | 805 | 710 | 650 | 670 | 590 | 535 | 805 | 725 | 610 | 770 | 670 | 610 |

| 2 | – | – | – | 725 | 630 | 510 | 610 | 510 | 430 | 725 | 630 | 550 | 690 | 590 | 490 | |

| 3 | – | – | – | 550 | 475 | 370 | 450 | 395 | 310 | 570 | 510 | 450 | 510 | 450 | 355 | |

| K | 1 | 1655 | 1520 | 1340 | 905 | 805 | 725 | – | – | – | 1165 | 1045 | 940 | – | – | – |

| 2 | 1320 | 1165 | 1080 | 710 | 630 | 590 | – | – | – | 925 | 830 | 750 | – | – | – | |

| 3 | 1105 | 985 | 905 | 590 | 535 | 475 | – | – | – | 770 | 690 | 630 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 |

| 2 | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 | |

| 3 | – | – | – | 200 | 155 | 95 | 180 | 140 | 95 | – | – | – | 200 | 155 | 120 | |

| 4 | – | – | – | 275 | 200 | 140 | 235 | 180 | 120 | 260 | 200 | 130 | 260 | 200 | 140 | |

| H | 1 | – | – | – | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |