Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Herramientas de alto rendimiento ya a la venta.

Compre ahora.

WIDIA a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Produtos

- /

- Fresado intercambiable

- /

- Fresas para escuadrado a 0°/90°

- /

- Serie VSM490-15

- /

- VSM490-15 Series - Tool Bodies

- /

- VSM490™-15 • Weldon® End Mills • Metric

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

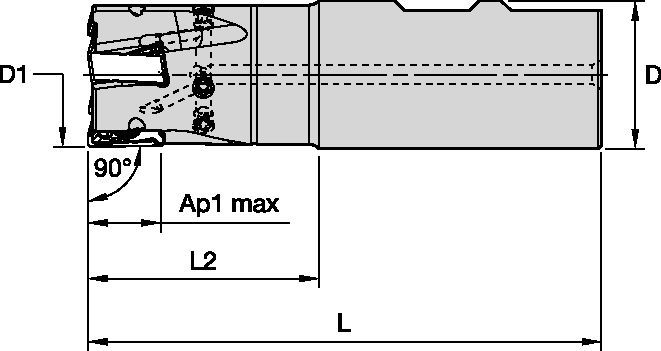

VSM490™-15 • Weldon® End Mills • Metric

Fresas de mango Weldon® • Sistema métrico

Features and benefits

Excelentes capacidades de acabado superficial y de pared.

Solución "sin pasos". 90° auténtico para funcionamiento de precisión

aplicaciones en varias pasadas axiales.

Un concepto resistente para trabajar hasta 15 mm (0,590″) de profundidad de corte.

Función de refrigeración interna altamente eficiente que llega al filo de corte

bordeado de precisión.

Uses and application

Planeado

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Placa cuadrada

Mango — Weldon cilíndrico

Fresado — Con refrigeración interna

Mecanizado de alojamientos

Guía para la selección de plaquitas

| Light

|

General

|

Heavy

|

||||

| Material

|

Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P3–P4 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P5–P6 | XNGU-MM | WP25PM | XNPU-MM | WP35CM | XNPU-MM | WP40PM |

| M1–M2 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| M3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| K1–K2 | XNPU-MM | WK15PM | XNGU-MH | WK15CM | XNGU-MH | WK15CM |

| K3 | XNPU-MM | WK15PM | XNGU-MH | WP35CM | XNGU-MH | WP35CM |

| N1–N2 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| N3 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| S1–S2 | XNGU-ML | WP25PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S4 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| H1 | – | – | – | – | – | – |

Avances iniciales recomendados [mm]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | 0,11 | 0,23 | 0,35 | 0,08 | 0,17 | 0,25 | 0,06 | 0,13 | 0,19 | 0,05 | 0,11 | 0,16 | 0,05 | 0,10 | 0,15 | .E..ALP |

| .E..ML | 0,17 | 0,31 | 0,46 | 0,13 | 0,23 | 0,33 | 0,09 | 0,17 | 0,25 | 0,08 | 0,15 | 0,22 | 0,08 | 0,14 | 0,20 | .E..ML |

| .S..MM | 0,22 | 0,40 | 0,64 | 0,16 | 0,29 | 0,46 | 0,12 | 0,22 | 0,34 | 0,10 | 0,19 | 0,30 | 0,10 | 0,18 | 0,28 | .S..MM |

| .S..MH | 0,23 | 0,45 | 0,74 | 0,17 | 0,33 | 0,54 | 0,13 | 0,24 | 0,40 | 0,11 | 0,21 | 0,35 | 0,10 | 0,20 | 0,32 | .S..MH |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | .005 | .008 | .012 | .003 | .006 | .009 | .002 | .004 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | .E..ALP |

| .E..ML | .007 | .012 | .018 | .005 | .009 | .013 | .004 | .006 | .010 | .003 | .006 | .008 | .003 | .005 | .008 | .E..ML |

| .S..MM | .008 | .015 | .024 | .006 | .011 | .017 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .007 | .010 | .S..MM |

| .S..MH | .009 | .017 | .028 | .006 | .012 | .020 | .005 | .009 | .015 | .004 | .008 | .013 | .004 | .007 | .012 | .S..MH |

| Light

|

General

|

Heavy

|

Velocidades iniciales recomendadas [m/min]*

| Material Group | WK15CM | WK15PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU35PM | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | 260 | 230 | 215 |

| 2 | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | 220 | 190 | 160 | |

| 3 | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | 200 | 170 | 140 | |

| 4 | – | – | – | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | 180 | 150 | 120 | |

| 5 | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | 150 | 135 | 120 | |

| 6 | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | 130 | 100 | 80 | |

| M | 1 | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | 170 | 150 | 135 |

| 2 | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | 155 | 130 | 110 | |

| 3 | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | 115 | 100 | 80 | |

| K | 1 | 420 | 385 | 340 | 270 | 245 | 215 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | – | – | – |

| 2 | 335 | 295 | 275 | 210 | 190 | 175 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | 175 | 160 | 145 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 |

| 2 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | |

| 3 | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | |

| 4 | – | – | – | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | 60 | 45 | 30 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]*

| Material Group | WK15CM | WK15PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU35PM | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 1085 | 935 | 885 | 1495 | 1295 | 1215 | 970 | 855 | 805 | – | – | – | 855 | 755 | 705 |

| 2 | – | – | – | – | – | – | – | – | – | 900 | 785 | 655 | 920 | 835 | 755 | 820 | 705 | 590 | – | – | – | 720 | 625 | 525 | |

| 3 | – | – | – | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 755 | 675 | 755 | 640 | 525 | – | – | – | 655 | 560 | 460 | |

| 4 | – | – | – | – | – | – | – | – | – | 740 | 605 | 490 | 625 | 575 | 525 | 675 | 560 | 445 | – | – | – | 590 | 490 | 395 | |

| 5 | – | – | – | – | – | – | – | – | – | 605 | 560 | 490 | 855 | 755 | 690 | 560 | 510 | 445 | 560 | 475 | 395 | 490 | 445 | 395 | |

| 6 | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 525 | 445 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | 425 | 330 | 260 | |

| M | 1 | – | – | – | – | – | – | – | – | – | 675 | 590 | 540 | 675 | 605 | 510 | 640 | 560 | 510 | 690 | 560 | 460 | 560 | 490 | 445 |

| 2 | – | – | – | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 525 | 460 | 575 | 490 | 410 | 590 | 475 | 395 | 510 | 425 | 360 | |

| 3 | – | – | – | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | 375 | 330 | 260 | |

| K | 1 | 1380 | 1265 | 1115 | 885 | 805 | 705 | – | – | – | 755 | 675 | 605 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 1100 | 970 | 900 | 690 | 625 | 575 | – | – | – | 590 | 525 | 490 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 920 | 820 | 755 | 575 | 525 | 475 | – | – | – | 490 | 445 | 395 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | 115 | 100 | 80 |

| 2 | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | 115 | 100 | 80 | |

| 3 | – | – | – | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | 150 | 115 | 80 | |

| 4 | – | – | – | – | – | – | – | – | – | 230 | 165 | 115 | – | – | – | 215 | 165 | 115 | 195 | 165 | 100 | 195 | 150 | 100 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |