Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao, User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account

Modifica account

Ship To Account

Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

-

Notifications

Mark all as read - Modifica password

- Il mio profilo

- Disconnetti

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso.

Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione: {{SolutionName}}- Prodotti

- /

- GTM21 • Pollici UNC • Adduzione interna di refrigerante

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

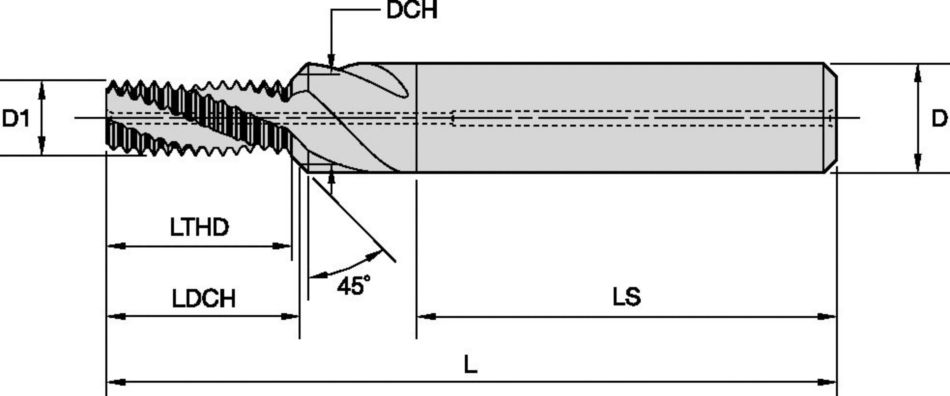

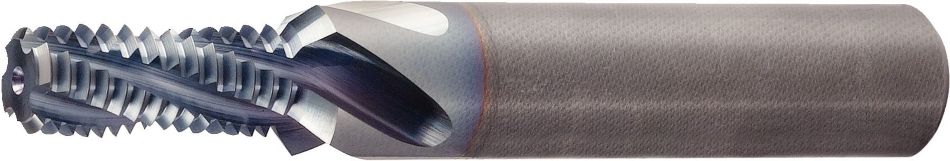

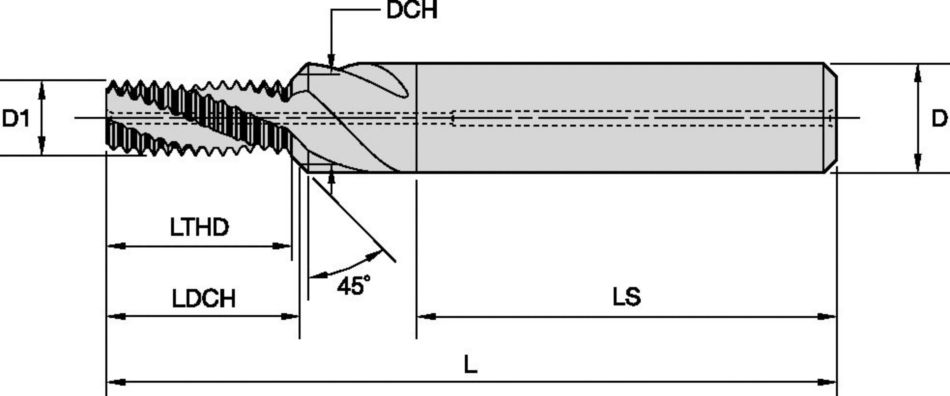

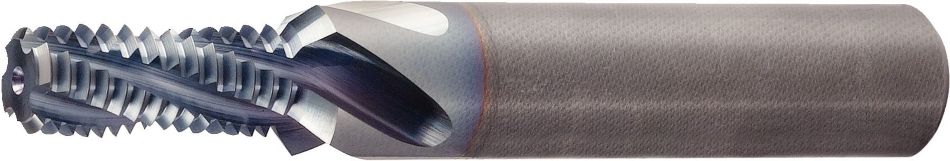

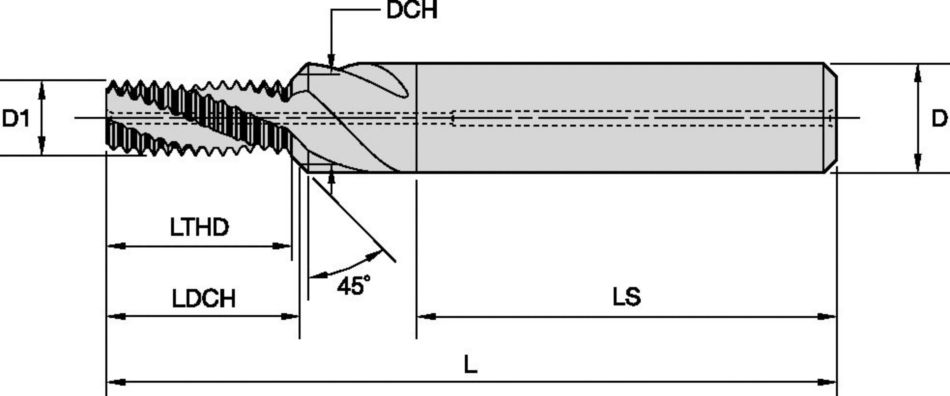

GTM21 • Pollici UNC • Adduzione interna di refrigerante

Frese a filettare in metallo duro Victory™ • Fori ciechi e passanti

Uses and application

Filettatura: Foro passante

Filettatura: Foro cieco

Svasatura/smussatura

Adduzione interna di refrigerante: Assiale: Maschiatura

HM

Profondità di foratura: 2x

Specifiche del costruttore: UNF

Specifiche del costruttore: UNC