ようこそ

設定をご確認ください

設定の更新

提案製品

Product Family suggestions

ソリューション編集

ソリューション追加

ソリューション名: {{SolutionName}}- 製品

- /

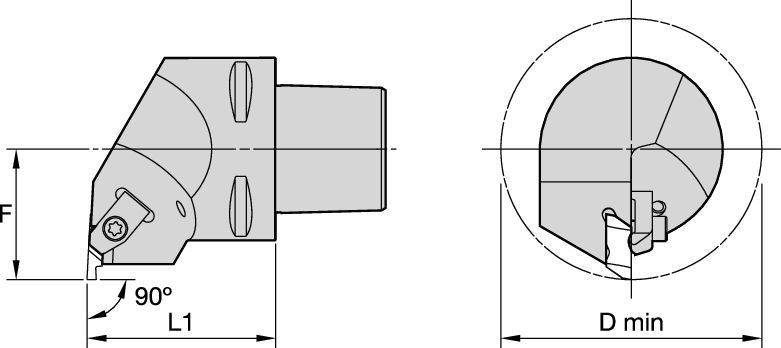

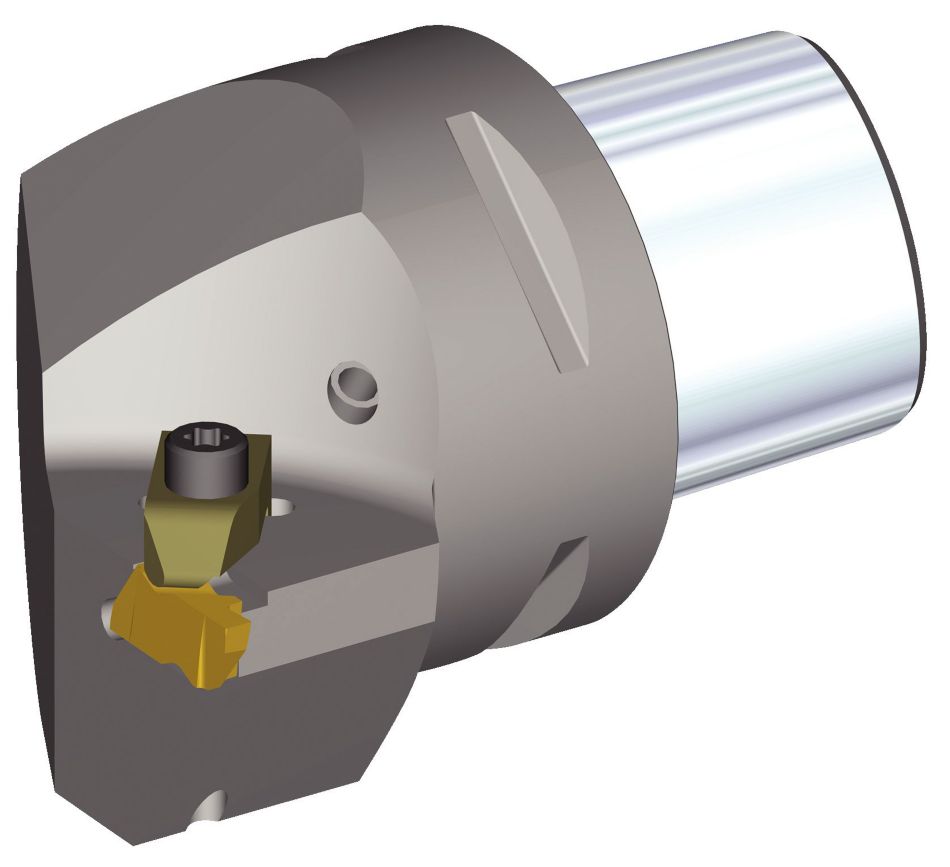

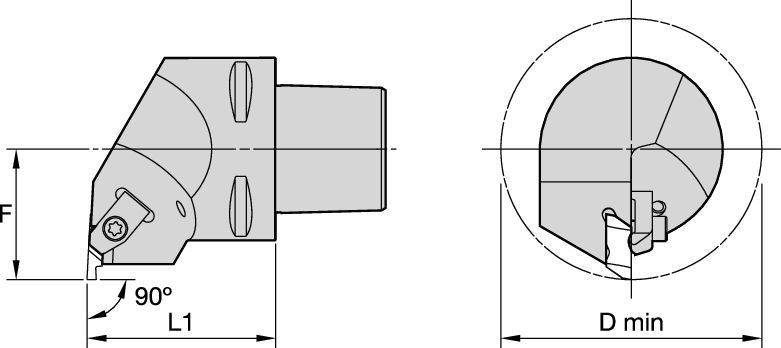

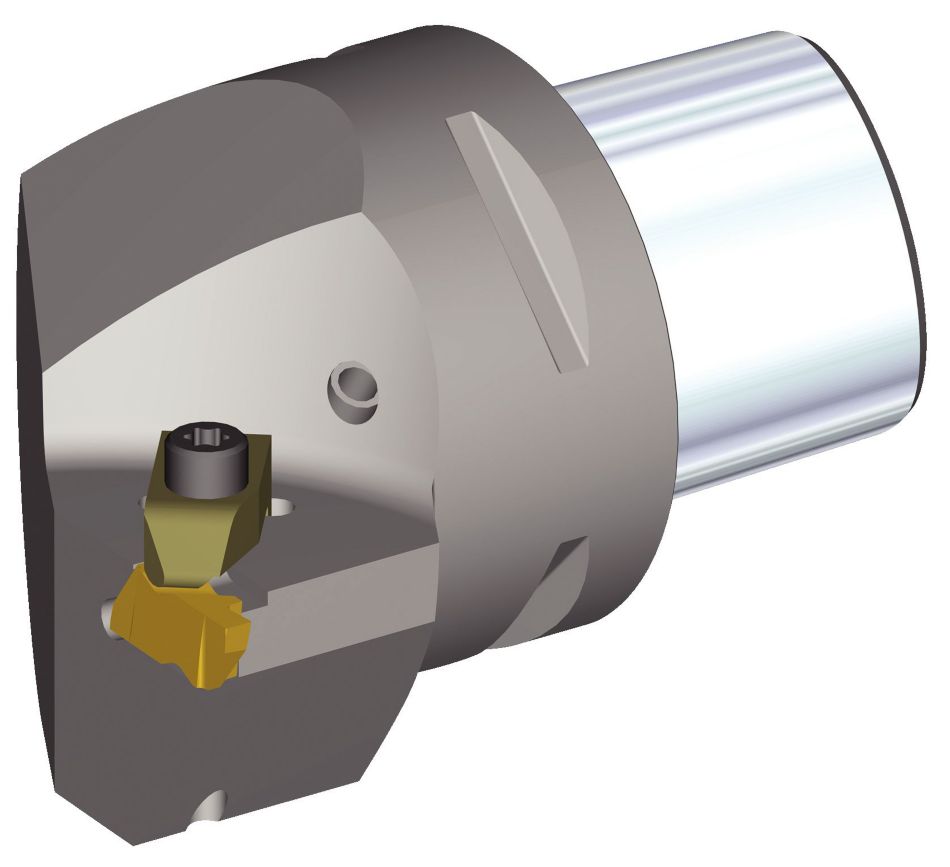

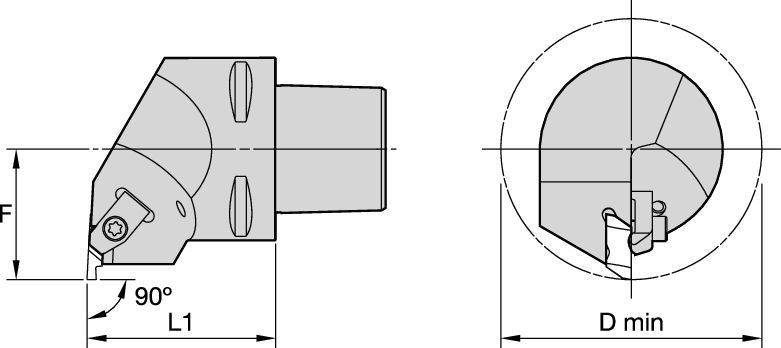

- NE 90°

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

NE 90°

Top Thread™ and Top Groove™ Threading and Grooving • Profiling

使用法と用途

メーカー仕様:ISO 26623

Shank - PSC

Coolant: Through Coolant 80 bar Maximum

Coolant: Through Coolant 1200 psi Maximum