Product Similar To:

Top Cut 4 • V36 Center Inserts • Low Power Consumption

First Choice for low power consumption.

Material Number5541840

ISO Catalog IDTCF040203ACV36ANSI Catalog IDTCF040203ACV36

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5541840 |

| ISO Catalog ID | TCF040203ACV36 |

| ANSI Catalog ID | TCF040203ACV36 |

| Grade | WU40PH |

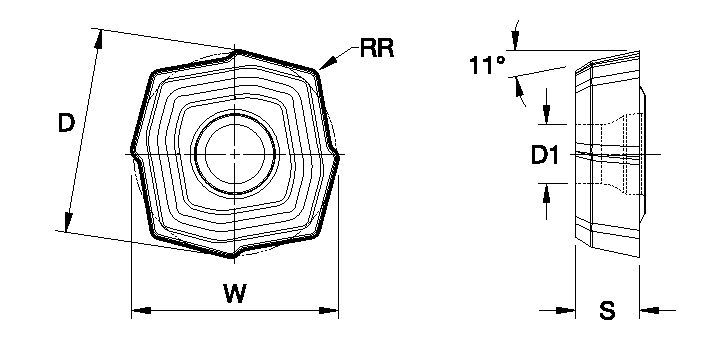

| [D] Insert IC Size | 4.47 mm |

| [D] Insert IC Size | 0.176 in |

| [D1] Insert Hole Size | 2.1 mm |

| [D1] Insert Hole Size | 0.083 in |

| [W] Cutting Width | 3.65 mm |

| [W] Cutting Width | 0.144 in |

| [S] Insert Thickness | 2 mm |

| [S] Insert Thickness | 0.079 in |

| [RR] Corner Radius | 0.3 mm |

| [RR] Corner Radius | 0.012 in |

| Insert Size | A |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Grades

WU40PH

Composition: With a multilayered PVD TiN-TiAlN coating and a tough substrate,

this grade withstands interruptions and provides high wear resistance for long tool life.

Application: First choice for high reliability in most materials. This grade should be

used at medium speeds and high feeds due to sharper edges and as a grade for high-

toughness applications. It covers steel, stainless steel, cast iron, and high-temp alloys

under certain conditions.

Features and benefits

- PSTS (Pressed and Sintered To Size) Inserts.

- Positive cutting edge.

- First choose for stainless steel.

- Best in deep hole application (4xD and 5xD).

- Suitable also for long chips steel and where a low power consumption is required.

- Periphery insert with Wiper land.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use