ProGroove™ - Blades and Blade Holders

Filters

Filters

View filters in

MetricInch

Workpiece Material

Workpiece Material

- P Steel (1)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(1)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(1)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(1)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(1)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(1)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(1)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(1)

- M Stainless Steel (1)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(1)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(1)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(1)

- K Cast Iron (1)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(1)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(1)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(1)

- N Non-Ferrous Materials (1)

- N1Wrought Aluminum (1)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(1)

- N3High-Silicon Aluminum Alloys Si >12.2%(1)

- N4Copper, Brass, Zinc-based on machinability index range of 70-100 (1)

- N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (1)

- N6Carbon, Graphite Composites, CFRP (1)

- N7MMC's (1)

- S High-Temp Alloys (1)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(1)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(1)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(1)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(1)

Applications

Applications

Cut-Off (1)

Deep Grooving (1)

Tool Cutting Edge Angle

Tool Cutting Edge Angle

- 90.0 (1)

to

Connection Style

Connection Style

- Toolholder (1)

Cutting Edges Per Insert

Cutting Edges Per Insert

- 1.0 (1)

to

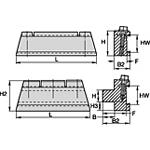

Over All Length [L]

Over All Length [L]

- 3.3858 in(1)

- 3.937 in(1)

- 4.3307 in(3)

to

Over All Length [L]

Over All Length [L]

- 86.0 mm(1)

- 100.0 mm(1)

- 110.0 mm(3)

to

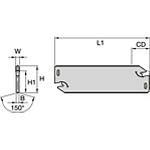

Corner Radius

Corner Radius

- 0.012 in(1)

to

Corner Radius

Corner Radius

- 0.3 mm(1)

to

Application

Grade Of Cutting Tool

Grade Of Cutting Tool

- TN6030 (1)

- WM35CT (1)

Hand Of Tool

Hand Of Tool

- N (1)

Wiper Insert

Wiper Insert

- N (1)

F Dimension

F Dimension

- 3.6 mm(1)

to

F Dimension

F Dimension

- 0.1417 in(1)

to

Cutting Direction

Cutting Direction

- E (1)

Rake Angle Style

Rake Angle Style

- NEUTRAL (ZERO) (1)

Front-End

Clamp Style

Clamp Style

- Y (1)

Cutting Width

Cutting Width

- 0.1614 in(1)

to

Cutting Width

Cutting Width

- 4.1 mm(1)

to

Insert Shape

Insert Shape

- PRISMATIC (1)

Maximum Cutting Depth

Maximum Cutting Depth

- 1.5748 in(1)

to

Maximum Cutting Depth

Maximum Cutting Depth

- 40.0 mm(1)

to

Insert Geometry

Cutting Tool Material

Cutting Tool Material

- H W (1)

Back-End

Shank Height

Shank Height

- 1.0236 in(1)

to

Shank Height

Shank Height

- 26.0 mm(1)

to

Shank Width

Shank Width

- 0.126 in(1)

to

Shank Width

Shank Width

- 3.2 mm(1)

to

No filters matching ""