Product Similar To :

RDPX-MM • RD1604..

iC16 • Inserts

Material Number3960515

ISO Catalog IDRDPX1604M0SNMMANSI Catalog IDRDPX1604M0SNMM

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3960515 |

| ISO Catalog ID | RDPX1604M0SNMM |

| ANSI Catalog ID | RDPX1604M0SNMM |

| Grade | TN6540 |

| Cutting Edges per Insert | 1 |

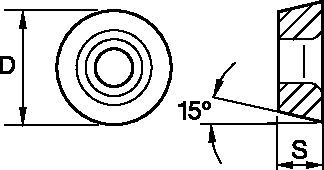

| [D] Insert IC Size | 16 mm |

| [D] Insert IC Size | 0.63 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.1874 in |

| Average Chip Thickness [HM] | 0.14 mm |

| Average Chip Thickness [HM] | 0.005 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Grades

TN6540

Coated carbide grade TN6540 has a PVD-TiAlN multilayer and is excellent for medium and heavy

machining applications. It is ideal for use in all steels and nodular cast irons.

Features and benefits

- -MM geometry is the first choice for general-purpose use, materials, and applications. Used for reduced cutting forces.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MM | 0,39 | 0,52 | 0,82 | 0,28 | 0,37 | 0,59 | 0,21 | 0,28 | 0,44 | 0,18 | 0,24 | 0,38 | 0,17 | 0,22 | 0,35 | MM |

| MH | 0,51 | 0,70 | 1,17 | 0,37 | 0,50 | 0,84 | 0,28 | 0,38 | 0,63 | 0,24 | 0,33 | 0,55 | 0,22 | 0,30 | 0,50 | MH |

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MM | 0,45 | 0,60 | 0,94 | 0,32 | 0,43 | 0,68 | 0,24 | 0,32 | 0,51 | 0,21 | 0,28 | 0,44 | 0,19 | 0,26 | 0,40 | MM |

| MH | 0,59 | 0,81 | 1,36 | 0,43 | 0,58 | 0,97 | 0,32 | 0,43 | 0,72 | 0,28 | 0,38 | 0,63 | 0,25 | 0,35 | 0,58 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MM | 0,81 | 1,08 | 1,71 | 0,58 | 0,78 | 1,22 | 0,43 | 0,58 | 0,91 | 0,38 | 0,51 | 0,79 | 0,35 | 0,46 | 0,72 | MM |

| MH | 1,06 | 1,46 | 2,48 | 0,76 | 1,04 | 1,75 | 0,57 | 0,78 | 1,30 | 0,50 | 0,68 | 1,13 | 0,45 | 0,62 | 1,03 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MM | 0,59 | 0,79 | 1,24 | 0,43 | 0,57 | 0,89 | 0,32 | 0,42 | 0,66 | 0,28 | 0,37 | 0,58 | 0,25 | 0,34 | 0,53 | MM |

| MH | 0,77 | 1,06 | 1,79 | 0,56 | 0,76 | 1,28 | 0,42 | 0,57 | 0,95 | 0,36 | 0,50 | 0,83 | 0,33 | 0,45 | 0,76 | MH |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | TN2505 | TN6525 | TN6540 | |||||||

| P | 1 | 550 | 420 | 360 | 410 | 320 | 280 | 360 | 280 | 240 |

| 2 | 320 | 240 | 205 | 320 | 250 | 215 | 250 | 190 | 170 | |

| 3 | 320 | 240 | 205 | 280 | 215 | 185 | 215 | 170 | 140 | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | |

| K | 1 | 400 | 300 | 250 | 275 | 245 | 220 | 220 | 205 | 180 |

| 2 | 540 | 365 | 280 | 215 | 190 | 180 | 175 | 155 | 140 | |

| 3 | 310 | 190 | 155 | 180 | 160 | 145 | 155 | 145 | 125 | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | |

| H | 1 | 175 | 140 | 95 | – | – | – | – | – | – |

| 2 | 175 | 140 | 95 | – | – | – | – | – | – | |

| 3 | 140 | 115 | 80 | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | MM | TN6525 | MM | TN6525 | MM | TN6540 |

| P3–P4 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| P5–P6 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| M1–M2 | – | – | MM | TN6525 | MM | TN6540 |

| M3 | – | – | MM | TN6525 | MM | TN6540 |

| K1–K2 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| K3 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | MM | TN6540 | – | – |

| S3 | – | – | MM | TN6540 | – | – |

| S4 | – | – | MM | TN6540 | – | – |

| H1 | MH | TN2505 | MH | TN2505 | – | – |

I have read and accepted the Terms & Conditions of use