M370 • 套式铣刀 • WO08... • 公制

套式铣刀 • 一般加工 • 公制

物料号4008277

公制样本编号M370D066Z06WO08英制样本编号M370D066Z06WO08

- P 钢

- M 不锈钢

- K 铸铁

- N 非铁材质

- S 高温合金

- H 淬火材料

- .caption

端面铣削

螺旋铣削

插铣

坡铣: 毛坯

槽铣: 方头立铣

3D仿形加工

铣削 — 贯通式冷却

铣削 — 侧铣和端面铣

侧铣/方肩铣削: 粗加工

刀座

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 4008277 |

| 公制样本编号 | M370D066Z06WO08 |

| 英制样本编号 | M370D066Z06WO08 |

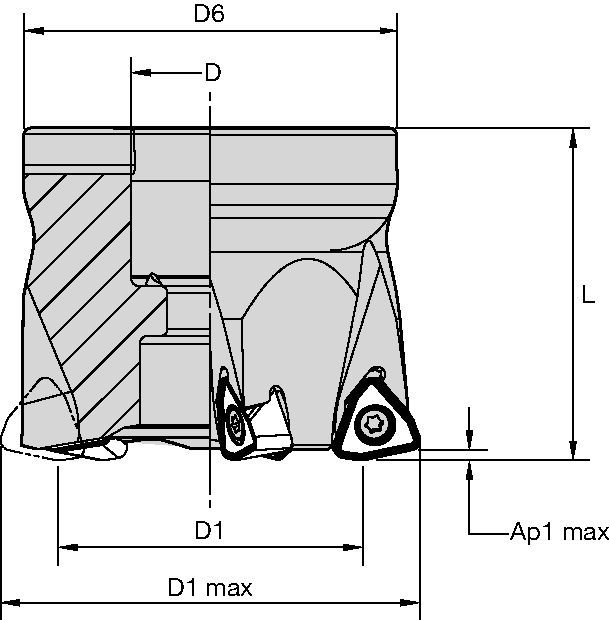

| [D1MAX] 最大切削直径 | 66 mm |

| [D1MAX] 最大切削直径 | 2.598 in |

| [D1] 有效的切削直径 | 51.9 mm |

| [D1] 有效的切削直径 | 2.04 in |

| [D]适配接头/刀柄/镗孔直径 | 27 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.063 in |

| [D6] 保护区孔直径 | 60 mm |

| [D6] 保护区孔直径 | 2.362 in |

| [L] 总长 | 50 mm |

| [L] 总长 | 1.969 in |

| [AP1MAX] 第一个最大切深 | 1.25 mm |

| [AP1MAX] 第一个最大切深 | 0.049 in |

| 刀片数量 | 6 |

| 最大 RPM | 24900 |

| 冷却液供应 | Y |

| 重量(千克) | 0.77 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 非铁材质

- 高温合金

- 淬火材料

- .caption

Uses and application

端面铣削

螺旋铣削

插铣

坡铣: 毛坯

槽铣: 方头立铣

3D仿形加工

铣削 — 贯通式冷却

铣削 — 侧铣和端面铣

侧铣/方肩铣削: 粗加工

刀座

Features and benefits

- 双面,六个切削刃。

- 具有最高的金属切削率。

- 粗加工应用的首选。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

建议的初始进给量 [毫米]

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ..MM | 0,90 | 1,67 | 4,09 | 0,65 | 1,19 | 2,83 | 0,48 | 0,88 | 2,08 | 0,42 | 0,77 | 1,80 | 0,38 | 0,70 | 1,64 | ..MM |

| ..MH | 0,90 | 2,34 | 5,00 | 0,65 | 1,66 | 3,41 | 0,48 | 1,23 | 2,49 | 0,42 | 1,07 | 2,16 | 0,38 | 0,98 | 1,97 | ..MH |

Recommended Starting Feeds [IPT]

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...MM | .035 | .061 | .150 | .025 | .044 | .104 | .019 | .033 | .076 | .017 | .028 | .066 | .015 | .026 | .061 | ...MM |

| ...MH | .035 | .092 | .197 | .025 | .065 | .134 | .019 | .048 | .098 | .017 | .042 | .085 | .015 | .038 | .078 | ...MH |

| 轻切削 | 中等切削 | 重切削 |

Speeds

| 材料 分组 | TN6525 | TN6540 | WK15CM | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU35PM | |||||||||||||||||||

| P | 1 | 1340 | 1045 | 925 | 1180 | 925 | 785 | – | – | – | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 1165 | 1025 | 965 | – | – | – | – | – | – | 850 | 750 | 705 |

| 2 | 1045 | 830 | 710 | 830 | 630 | 550 | – | – | – | 1080 | 940 | 785 | 1105 | 1000 | 905 | 985 | 845 | 710 | – | – | – | – | – | – | 720 | 620 | 520 | |

| 3 | 925 | 710 | 610 | 710 | 550 | 450 | – | – | – | 1000 | 845 | 690 | 1000 | 905 | 805 | 905 | 770 | 630 | – | – | – | – | – | – | 655 | 555 | 455 | |

| 4 | 770 | 550 | 475 | 590 | 430 | 355 | – | – | – | 890 | 725 | 590 | 750 | 690 | 630 | 805 | 670 | 535 | – | – | – | – | – | – | 590 | 490 | 390 | |

| 5 | 1025 | 770 | 650 | 785 | 590 | 490 | – | – | – | 725 | 670 | 590 | 1025 | 905 | 830 | 670 | 610 | 535 | – | – | – | 560 | 475 | 395 | 490 | 440 | 390 | |

| 6 | 670 | 535 | 430 | 535 | 395 | 335 | – | – | – | 650 | 490 | 395 | 630 | 535 | 430 | 590 | 450 | 355 | – | – | – | 490 | 360 | 260 | 425 | 325 | 260 | |

| M | 1 | 630 | 395 | 260 | 430 | 260 | 200 | – | – | – | 805 | 710 | 650 | 805 | 725 | 610 | 770 | 670 | 610 | 890 | 785 | 725 | 690 | 560 | 460 | 555 | 490 | 440 |

| 2 | 395 | 260 | 155 | 260 | 155 | 140 | – | – | – | 725 | 630 | 510 | 725 | 630 | 550 | 690 | 590 | 490 | 805 | 710 | 570 | 590 | 475 | 395 | 505 | 425 | 360 | |

| 3 | 415 | 260 | 180 | 275 | 155 | 140 | – | – | – | 550 | 475 | 370 | 570 | 510 | 450 | 510 | 450 | 355 | 610 | 535 | 415 | 475 | 360 | 280 | 375 | 325 | 260 | |

| K | 1 | 905 | 805 | 725 | 725 | 670 | 590 | 1655 | 1520 | 1340 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 710 | 630 | 590 | 570 | 510 | 450 | 1320 | 1165 | 1080 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 535 | 475 | 510 | 475 | 415 | 1105 | 985 | 905 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 155 | 120 | 95 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 |

| 2 | – | – | – | 80 | 60 | 40 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 | |

| 3 | – | – | – | 235 | 140 | 95 | – | – | – | 200 | 155 | 95 | – | – | – | 200 | 155 | 120 | 215 | 180 | 120 | 165 | 130 | 80 | 145 | 110 | 80 | |

| 4 | – | – | – | 200 | 95 | 80 | – | – | – | 275 | 200 | 140 | 260 | 200 | 130 | 260 | 200 | 140 | 335 | 235 | 155 | 195 | 165 | 100 | 195 | 145 | 95 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

High Performance Combination Tools

刀片选择指南

| 轻切削 | 中等切削 | 重切削 | ||||

| 材料 分组 | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | ...MM | WP40PM | ...MM | WP40PM | ...MM | WP40PM |

| P3–P4 | ...MM | WP25PM | ...MM | WP40PM | ...MH | WP40PM |

| P5–P6 | ...MM | WP25PM | ...MH | WP25PM | ...MH | WP40PM |

| M1–M2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| M3 | ...MM | WP25PM | ...MM | WP25PM | ...MM | WP40PM |

| K1–K2 | ...MH | WK15CM | ...MH | WK15CM | ...MH | WK15CM |

| K3 | ...MH | TN6520 | ...MH | TN6520 | ...MH | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| S3 | ...MM | WS30PM | ...MM | WS30PM | ...MM | WP40PM |

| S4 | ...MM | WS30PM | ...MM | WP40PM | ...MM | WP40PM |

| H1 | ...MH | WP25PM | – | – | – | – |

I have read and accepted the Terms & Conditions of use