Product Similar To :

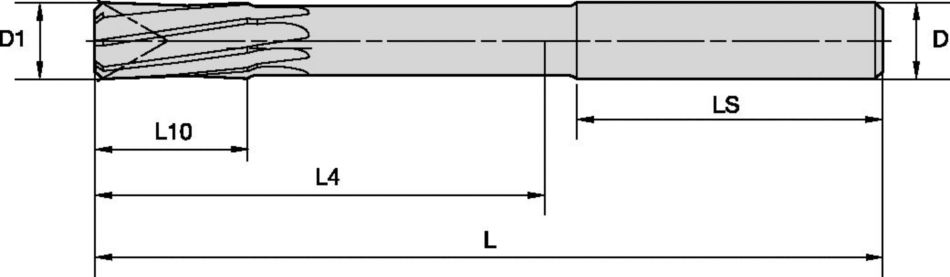

GP Reamers for Through Holes • 1,4–10,0mm • Helical Flute • K10 • Uncoated • Cylindrical Shank

HSR™ Solid Carbide Reaming Tools

Material Number2293640

ISO Catalog ID050221-000045ANSI Catalog ID050221-000045

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Reaming: Through & Cross Holes

DIN number 212

Flood Coolant: Reaming

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2293640 |

| ISO Catalog ID | 050221-000045 |

| ANSI Catalog ID | 050221-000045 |

| Grade | K10 |

| [D1] Reamer Diameter Minimum | 4.5 mm |

| [D1] Reamer Diameter Minimum | 0.177 in |

| [D] Adapter / Shank / Bore Diameter | 4.5 mm |

| [D] Adapter / Shank / Bore Diameter | 0.1772 in |

| [L] Overall Length | 80 mm |

| [L] Overall Length | 3.1496 in |

| [L4] Maximum Reaming Depth | 44 mm |

| [L4] Maximum Reaming Depth | 1.732 in |

| [L10] Cutting Edge Length | 21 mm |

| [L10] Cutting Edge Length | 0.8268 in |

| [LS] Shank Length | 33 mm |

| [LS] Shank Length | 1.2992 in |

| [Z] Number of Flutes | 6 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Reaming: Through & Cross Holes

DIN number 212

Flood Coolant: Reaming

Grades

K10

Composition: Uncoated, highly wear-resistant fine-grain carbide with enhanced hot hardness properties.

Application: Best suited for dry and external flood coolant applications in aerospace materials like high-temperature resistant materials and wrought aluminum alloys. Due to its high wear-resistance, this grade is also applicable for cast iron machining at low to medium speeds.

Features and benefits

- Provide your exact hole diameter and tolerance when ordering, or use form on page [REFERENCE].

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use