Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Finishers • Series 4S07 • Sharp Edge • Inch

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

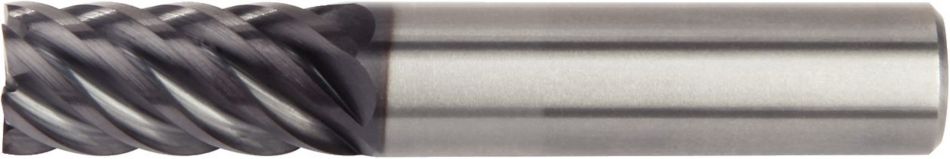

Finishers • Series 4S07 • Sharp Edge • Inch

Series 4S07 • Inch

Features and benefits

- Center cutting.

- Standard items listed. Additional styles and coatings made-to-order.

Uses and application

Ramping: Blank

Corner Style: Square End

Shank - Cylindrical Plain

Side Milling/Shoulder Milling: Square End

Helix Angle: 45°

Tool Dimensions: Flute Configuration: 6

Series 4S07 • Victory Grades

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||||||

| Side Milling (A) | WP15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Cutting Speed

|

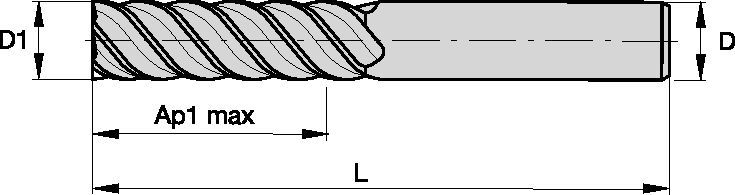

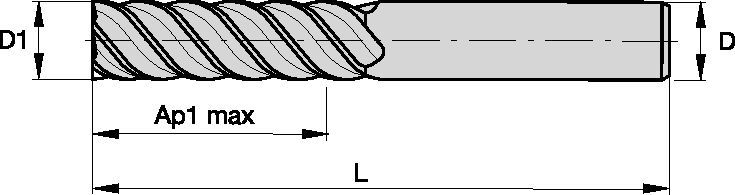

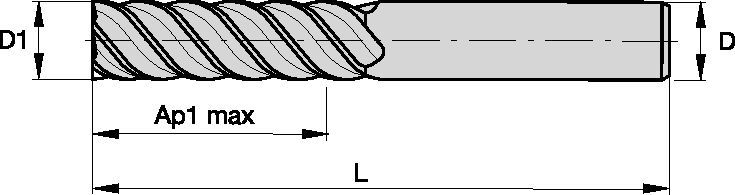

D1

|

|||||||||||||||

| frac. | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| Material

|

ap | ae | Min | Max | dec. | .1250 | .1875 | .2500 | .3125 | .3750 | .4375 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | 1 x D | 0.2 x D | 490 | – | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 |

| 1 | 1 x D | 0.2 x D | 490 | – | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 | |

| 2 | 1 x D | 0.2 x D | 460 | – | 620 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 1 x D | 0.1 x D | 390 | – | 520 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| 4 | 1 x D | 0.1 x D | 300 | – | 490 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0039 | |

| 5 | 1 x D | 0.1 x D | 200 | – | 330 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 | |

| 6 | 1 x D | 0.1 x D | 160 | – | 250 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | |

| M | 1 | 1 x D | 0.1 x D | 300 | – | 380 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1 x D | 0.1 x D | 200 | – | 260 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 | |

| 3 | 1 x D | 0.1 x D | 200 | – | 230 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | |

| K | 1 | 1 x D | 0.1 x D | 390 | – | 490 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 |

| 2 | 1 x D | 0.1 x D | 360 | – | 460 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 1 x D | 0.1 x D | 360 | – | 430 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 | |

| S | 1 | 1 x D | 0.1 x D | 160 | – | 300 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1 x D | 0.1 x D | 80 | – | 130 | IPT | .0004 | .0006 | .0008 | .0010 | .0012 | .0014 | .0015 | .0018 | .0021 | .0024 | |

| 3 | 1 x D | 0.15 x D | 80 | – | 130 | IPT | .0004 | .0006 | .0008 | .0010 | .0012 | .0014 | .0015 | .0018 | .0021 | .0024 | |

| 4 | 1 x D | 0.15 x D | 160 | – | 200 | IPT | .0005 | .0008 | .0011 | .0014 | .0017 | .0019 | .0021 | .0025 | .0028 | .0033 | |

| H | 1 | 1 x D | 0.1 x D | 260 | – | 460 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0039 |