Produit similaire à:

M690 • SDMT-MH • SD1506..

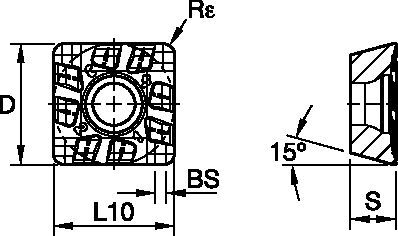

Plaquettes • SDMT-MH

Numéro de matériel2030415

Ref. ISO CatalogueSDMT1506PDRMHRef. ANSI CatalogueSDMT54PDRMH

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 2030415 |

| Ref. ISO Catalogue | SDMT1506PDRMH |

| Ref. ANSI Catalogue | SDMT54PDRMH |

| Nuance | TN450 |

| Arêtes de coupe par plaquette | 4 |

| [D] Taille de plaquette CI | 15.875 mm |

| [D] Taille de plaquette CI | 0.625 in |

| [L10] Longueur d’arête de coupe de la plaquette | 15.875 mm |

| [L10] Longueur d’arête de coupe de la plaquette | 0.625 in |

| [S] Épaisseur de la plaquette | 6.35 mm |

| [S] Épaisseur de la plaquette | 0.25 in |

| [BS] Longueur de facette d’angle | 1.1 mm |

| [BS] Longueur de facette d’angle | 0.043 in |

| [Rε] Rayon de bec | 1.2 mm |

| [Rε] Rayon de bec | 0.047 in |

| Épaisseur moyenne du copeau [HM] | 0.07 mm |

| Épaisseur moyenne du copeau [HM] | 0.0028 in |

Grades

TN450

Nuance de carbure revêtu

- revêtement multicouche CVD-TiN-TiCN-TiN

- usinage général et lourd

- pour l’usinage de tous les types d’acier et de fonte nodulaire

- arrosage recommandé

- nuance extrêmement résistante, résistant aux changements de température

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Feeds

Avances de départ recommandées [mm]

| Géométrie de plaquette | Avance par dent (fz) programmée en % de l'engagement radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,23 | 0,46 | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | .F..ALP |

| .E..ML | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..ML |

| .S..MM | 0,12 | 0,42 | 0,70 | 0,08 | 0,30 | 0,50 | 0,06 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,05 | 0,18 | 0,30 | .S..MM |

| .S..MH | 0,23 | 0,54 | 0,85 | 0,17 | 0,39 | 0,61 | 0,13 | 0,29 | 0,46 | 0,11 | 0,25 | 0,40 | 0,10 | 0,23 | 0,36 | .S..MH |

| Travaux légers | Applications générales | Travaux lourds |

Avances de départ recommandées [mm]

| Géométrie de plaquette | Avance par dent (fz) programmée en % de l'engagement radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,23 | 0,46 | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | .F..ALP |

| .E..ML | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..ML |

| .S..MM | 0,12 | 0,42 | 0,70 | 0,08 | 0,30 | 0,50 | 0,06 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,05 | 0,18 | 0,30 | .S..MM |

| .S..MH | 0,23 | 0,54 | 0,85 | 0,17 | 0,39 | 0,61 | 0,13 | 0,29 | 0,46 | 0,11 | 0,25 | 0,40 | 0,10 | 0,23 | 0,36 | .S..MH |

| Travaux légers | Applications générales | Travaux lourds |

Recommended Starting Feeds [IPT]

| Géométrie de plaquette | Avance par dent (fz) programmée en % de l'engagement radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .009 | .019 | .003 | .007 | .013 | .003 | .005 | .010 | .002 | .004 | .009 | .002 | .004 | .008 | .F..ALP |

| .E..ML | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .E..ML |

| .S..MM | .005 | .016 | .027 | .003 | .012 | .020 | .003 | .009 | .015 | .002 | .008 | .013 | .002 | .007 | .012 | .S..MM |

| .S..MH | .009 | .021 | .033 | .007 | .015 | .024 | .005 | .011 | .018 | .004 | .010 | .016 | .004 | .009 | .014 | .S..MH |

| Travaux légers | Applications générales | Travaux lourds |

Recommended Starting Feeds [IPT]

| Géométrie de plaquette | Avance par dent (fz) programmée en % de l'engagement radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .E..ML | .007 | .019 | .032 | .005 | .014 | .023 | .004 | .010 | .017 | .003 | .009 | .015 | .003 | .008 | .014 | .E..ML |

| .S..MM | .008 | .021 | .035 | .006 | .015 | .025 | .004 | .011 | .019 | .004 | .010 | .016 | .003 | .009 | .015 | .S..MM |

| .S..MH | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..MH |

| Travaux légers | Applications générales | Travaux lourds |

Speeds

Vitesses de départ recommandées [m/mn]

| Groupe Matières | TN6520 | TN6525 | TN6540 | WP35CM | |||||||||

| P | 0 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | – | – | – |

| 1 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | 455 | 395 | 370 | |

| 2 | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | 280 | 255 | 230 | |

| 3 | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | 255 | 230 | 205 | |

| 4 | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | 190 | 175 | 160 | |

| 5 | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | 260 | 230 | 210 | |

| 6 | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | 160 | 135 | 110 | |

| M | 1 | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 | 205 | 185 | 155 |

| 2 | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | 185 | 160 | 140 | |

| 3 | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | 145 | 130 | 115 | |

| K | 1 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 | 295 | 265 | 240 |

| 2 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | 235 | 210 | 190 | |

| 3 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 30 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 20 | 15 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 35 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 25 | 20 | 66 | 50 | 33 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| Groupe Matières | WK15CM | WK15PM | WS30PM | WS40PM | THM-U | |||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 1 | – | – | – | – | – | – | – | – | – | 280 | 245 | 230 | – | – | – | |

| 2 | – | – | – | – | – | – | – | – | – | 235 | 205 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 215 | 185 | 150 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 195 | 160 | 130 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 160 | 140 | 130 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | 140 | 110 | 85 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 225 | 200 | 185 | 260 | 190 | 115 | – | – | – |

| 2 | – | – | – | – | – | – | 205 | 180 | 145 | 230 | 170 | 105 | – | – | – | |

| 3 | – | – | – | – | – | – | 155 | 135 | 105 | 190 | 140 | 80 | – | – | – | |

| K | 1 | 420 | 385 | 340 | 360 | 290 | 245 | – | – | – | – | – | – | 190 | 170 | 150 |

| 2 | 335 | 295 | 275 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1075 | 945 | 945 | 2000 | 1200 | 1000 |

| 2 | – | – | – | – | – | – | – | – | – | 945 | 875 | 845 | 1365 | 815 | 665 | |

| 3 | – | – | – | – | – | – | – | – | – | 875 | 760 | 760 | 800 | 500 | 400 | |

| S | 1 | – | – | – | – | – | – | 45 | 40 | 30 | 62 | 45 | 27 | – | – | – |

| 2 | – | – | – | – | – | – | 45 | 40 | 30 | 55 | 40 | 26 | – | – | – | |

| 3 | – | – | – | – | – | – | 55 | 45 | 30 | 64 | 46 | 29 | – | – | – | |

| 4 | – | – | – | – | – | – | 85 | 60 | 40 | 90 | 66 | 42 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Vitesses de départ recommandées [m/mn]

| Groupe Matières | TN6520 | TN6525 | TN6540 | WP35CM | |||||||||

| P | 0 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | – | – | – |

| 1 | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | 455 | 395 | 370 | |

| 2 | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | 280 | 255 | 230 | |

| 3 | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | 255 | 230 | 205 | |

| 4 | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | 190 | 175 | 160 | |

| 5 | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | 260 | 230 | 210 | |

| 6 | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | 160 | 135 | 110 | |

| M | 1 | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 | 205 | 185 | 155 |

| 2 | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | 185 | 160 | 140 | |

| 3 | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | 145 | 130 | 115 | |

| K | 1 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 | 295 | 265 | 240 |

| 2 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | 235 | 210 | 190 | |

| 3 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 30 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 20 | 15 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 35 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 25 | 20 | 66 | 50 | 33 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| Groupe Matières | WK15CM | WK15PM | WS30PM | WS40PM | THM-U | |||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 1 | – | – | – | – | – | – | – | – | – | 280 | 245 | 230 | – | – | – | |

| 2 | – | – | – | – | – | – | – | – | – | 235 | 205 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 215 | 185 | 150 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 195 | 160 | 130 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 160 | 140 | 130 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | 140 | 110 | 85 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 225 | 200 | 185 | 260 | 190 | 115 | – | – | – |

| 2 | – | – | – | – | – | – | 205 | 180 | 145 | 230 | 170 | 105 | – | – | – | |

| 3 | – | – | – | – | – | – | 155 | 135 | 105 | 190 | 140 | 80 | – | – | – | |

| K | 1 | 420 | 385 | 340 | 360 | 290 | 245 | – | – | – | – | – | – | 190 | 170 | 150 |

| 2 | 335 | 295 | 275 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1075 | 945 | 945 | 2000 | 1200 | 1000 |

| 2 | – | – | – | – | – | – | – | – | – | 945 | 875 | 845 | 1365 | 815 | 665 | |

| 3 | – | – | – | – | – | – | – | – | – | 875 | 760 | 760 | 800 | 500 | 400 | |

| S | 1 | – | – | – | – | – | – | 45 | 40 | 30 | 62 | 45 | 27 | – | – | – |

| 2 | – | – | – | – | – | – | 45 | 40 | 30 | 55 | 40 | 26 | – | – | – | |

| 3 | – | – | – | – | – | – | 55 | 45 | 30 | 64 | 46 | 29 | – | – | – | |

| 4 | – | – | – | – | – | – | 85 | 60 | 40 | 90 | 66 | 42 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Guide de sélection des plaquettes

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance | |

| P1–P2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P3–P4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P5–P6 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M1–M2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M3 | .E..ML | WS40PM | .S..MM | WS40PM | .S..MH | WP35CM |

| K1–K2 | .E..ML | WK15CM | .E..ML | WK15CM | .S..MH | WK15CM |

| K3 | .E..ML | WK15CM | .S..MM | TN6525 | .S..MH | TN6525 |

| N1–N2 | .ALP | THM-U | .E..ML | THM-U | .S..ML | THM-U |

| N3 | .ALP | THM-U | .E..ML | THM-U | .S..ML | THM-U |

| S1–S2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S3 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| S4 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| H1 | .S..MM | WS30PM | .S..MM | WS30PM | .S..MM | WS30PM |

Guide de sélection des plaquettes

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance | |

| P1–P2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P3–P4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P5–P6 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M1–M2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M3 | .E..ML | TN6540 | .S..MM | WP35CM | .S..MH | WP35CM |

| K1–K2 | .E..ML | WK15CM | .E..ML | WK15CM | .S..MH | WK15CM |

| K3 | .E..ML | WK15CM | .S..MM | WK15CM | .S..MH | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S3 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| H1 | .S..MM | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data