Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao, User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account Modifica account

Ship To Account Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

Notifications

Mark all as read- Modifica password

- Il mio profilo

- Disconnetti

Articolo/i aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso. Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione:{{SolutionName}}- Prodotti

- /

- M1600 • ONGX-MM • Spianatura generica

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

M1600 • ONGX-MM • Spianatura generica

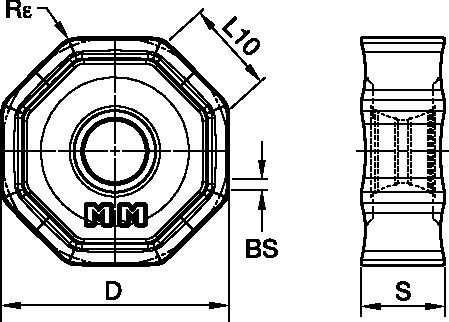

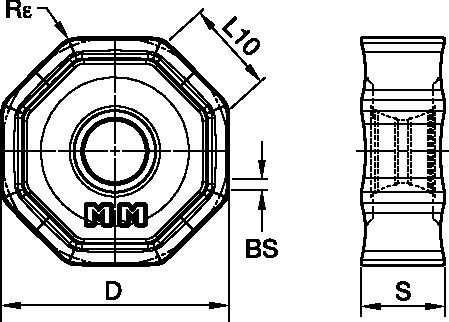

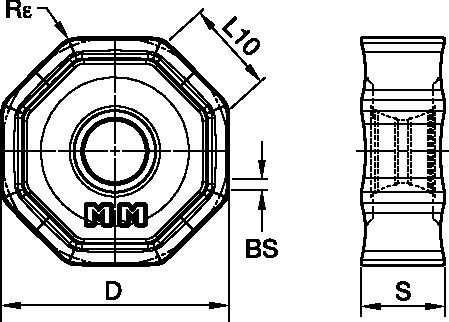

Inserti • ONGX-MM • Lavorazione a basso costo per tagliente

Guida alla selezione degli inserti

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WU20PM |

| P3–P4 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WU20PM |

| P5–P6 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WP35CM |

| M1–M2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| M3 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WP35CM |

| K1–K2 | .S..MM | WK15CM | .S..MM | WK15CM | .S..MM | WU20PM |

| K3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WK15CM |

| N1–N2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| N3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S1–S2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S4 | .S..MM | WP35CM | .S..MM | WU20PM | .S..MM | WU20PM |

| H1 | .S..MM | WU20PM | – | – | – | – |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .S..MM | 0,26 | 0,85 | 1,42 | 0,19 | 0,62 | 1,01 | 0,14 | 0,46 | 0,75 | 0,12 | 0,40 | 0,66 | 0,11 | 0,37 | 0,60 | .S..MM |

| Light | General | Heavy |

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| .S..MM | .010 | .034 | .056 | .007 | .024 | .040 | .005 | .018 | .030 | .005 | .016 | .026 | .004 | .014 | .024 | .S..MM |

| Material Group | WP35CM | WK15CM | WU20PM | |||||||

| P | 1 | 455 | 395 | 370 | — | — | — | 330 | 290 | 270 |

| 2 | 280 | 255 | 230 | — | — | — | 275 | 250 | 200 | |

| 3 | 255 | 230 | 205 | — | — | — | 255 | 220 | 175 | |

| 4 | 190 | 175 | 160 | — | — | — | 225 | 190 | 150 | |

| 5 | 260 | 230 | 210 | — | — | — | 185 | 175 | 150 | |

| 6 | 160 | 135 | 110 | — | — | — | 165 | 130 | 100 | |

| M | 1 | 205 | 185 | 155 | — | — | — | 205 | 180 | 165 |

| 2 | 185 | 160 | 140 | — | — | — | 185 | 160 | 130 | |

| 3 | 145 | 130 | 115 | — | — | — | 140 | 120 | 95 | |

| K | 1 | 295 | 265 | 240 | 420 | 385 | 340 | 250 | 220 | 185 |

| 2 | 235 | 210 | 190 | 335 | 295 | 275 | 200 | 180 | 150 | |

| 3 | 195 | 175 | 160 | 280 | 250 | 230 | 180 | 150 | 120 | |

| N | 1 | — | — | — | — | — | — | 550 | 470 | 400 |

| 2 | — | — | — | — | — | — | 550 | 470 | 400 | |

| 3 | — | — | — | — | — | — | 400 | 350 | 300 | |

| S | 1 | — | — | — | — | — | — | 40 | 35 | 25 |

| 2 | — | — | — | — | — | — | 40 | 35 | 25 | |

| 3 | — | — | — | — | — | — | 50 | 40 | 25 | |

| 4 | — | — | — | — | — | — | 70 | 50 | 35 | |

| H | 1 | — | — | — | — | — | — | 110 | 80 | 70 |

| Material Group | WP35CM | WK15CM | WU20PM | |||||||

| P | 1 | 1490 | 1300 | 1210 | — | — | — | 1080 | 950 | 890 |

| 2 | 920 | 840 | 750 | — | — | — | 900 | 820 | 660 | |

| 3 | 840 | 750 | 670 | — | — | — | 840 | 720 | 570 | |

| 4 | 620 | 570 | 520 | — | — | — | 740 | 620 | 490 | |

| 5 | 850 | 750 | 690 | — | — | — | 610 | 570 | 490 | |

| 6 | 520 | 440 | — | — | — | — | 540 | 430 | 330 | |

| M | 1 | 670 | 610 | 510 | — | — | — | 670 | 590 | 540 |

| 2 | 610 | 520 | 460 | — | — | — | 610 | 520 | 430 | |

| 3 | 480 | 430 | 380 | — | — | — | 460 | 390 | 310 | |

| K | 1 | 970 | 870 | 790 | 1380 | 1260 | 1120 | 820 | 720 | 610 |

| 2 | 770 | 690 | 620 | 1100 | 970 | 900 | 660 | 590 | 490 | |

| 3 | 640 | 570 | 520 | 920 | 820 | 750 | 590 | 490 | 390 | |

| N | 1 | — | — | — | — | — | — | 1800 | 1540 | 1310 |

| 2 | — | — | — | — | — | — | 1800 | 1540 | 1310 | |

| 3 | — | — | — | — | — | — | 1310 | 1150 | 980 | |

| S | 1 | — | — | — | — | — | — | 130 | 110 | 80 |

| 2 | — | — | — | — | — | — | 130 | 110 | 80 | |

| 3 | — | — | — | — | — | — | 160 | 130 | 80 | |

| 4 | — | — | — | — | — | — | 230 | 160 | 110 | |

| H | 1 | — | — | — | — | — | — | 360 | 260 | 230 |