Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao,

User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account

Modifica account

Ship To Account

Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

-

Notifications

Mark all as read - Modifica password

- Il mio profilo

- Disconnetti

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso.

Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione: {{SolutionName}}- Prodotti

- /

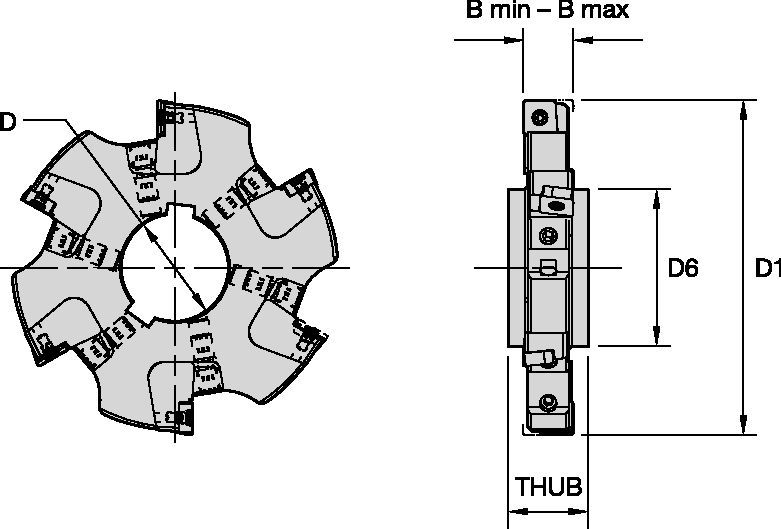

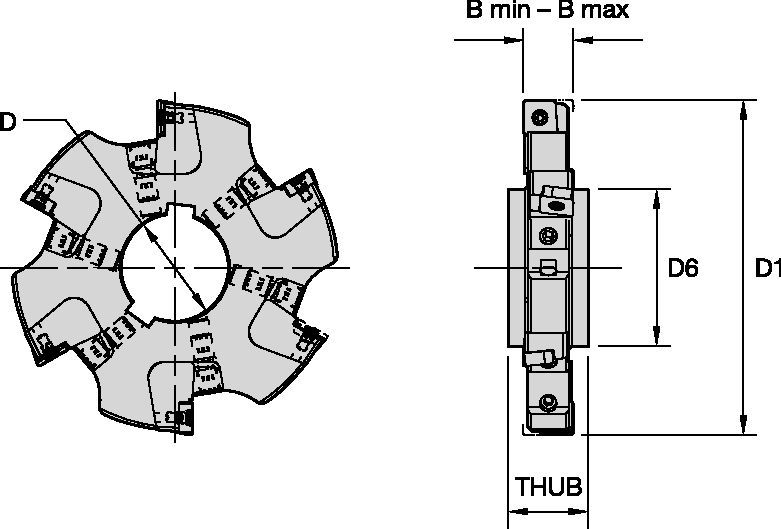

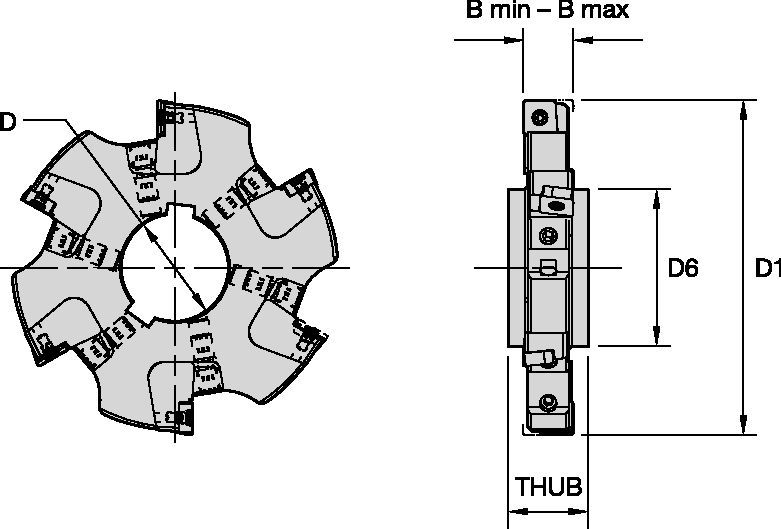

- M900 • Frese a Disco • 12mm

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

M900 • Frese a Disco • 12mm

Montaggio ad albero • 12mm

Uses and application

Scanalatura: Lato

Scanalatura: Lato con dimensioni AE/AP

Contornatura/fresatura a spallamento: Testa quadrata con dimensioni AE/AP

Contornatura/fresatura a spallamento: Testa piana

M900 Cutting Data • MDH.. • P Coating

| TN7525 | TN7535 | TN450 | TTM | TTR | |||||||||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||||||||||||||

| M900 | MDHX09T308 | – | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material

|

vc (m/min) | ||||||||||||||||

| P | 1 | 330 | 250 | 210 | 280 | 215 | 185 | 250 | 215 | 200 | 170 | 150 | 140 | 135 | 120 | 110 | |

| 2 | 250 | 195 | 170 | 190 | 150 | 130 | 180 | 150 | 140 | 120 | 100 | 90 | 95 | 80 | 70 | ||

| 3 | 210 | 160 | 145 | 160 | 120 | 110 | 150 | 130 | 120 | 100 | 80 | 70 | 80 | 65 | 55 | ||

| 4 | 215 | 170 | 145 | 165 | 130 | 110 | 160 | 140 | 130 | 110 | 85 | 80 | 90 | 70 | 65 | ||

| 5 | 185 | 130 | 115 | 140 | 100 | 85 | 130 | 110 | 100 | 85 | 70 | 60 | 70 | 55 | 50 | ||

| 6 | 240 | 185 | 150 | 185 | 140 | 115 | 180 | 150 | 140 | 120 | 100 | 90 | 95 | 80 | 70 | ||

| 7 | 185 | 145 | 120 | 140 | 110 | 90 | 140 | 120 | 110 | 90 | 80 | 70 | 70 | 65 | 55 | ||

| 8 | 160 | 120 | 105 | 120 | 90 | 80 | 120 | 100 | 90 | 80 | 60 | 55 | 65 | 50 | 45 | ||

| 9 | 145 | 105 | 90 | 110 | 80 | 70 | 100 | 70 | 60 | 70 | 50 | 40 | 55 | 40 | 30 | ||

| 10 | 185 | 145 | 130 | 140 | 110 | 100 | 160 | 135 | 120 | 110 | 85 | 80 | 90 | 70 | 65 | ||

| 11 | 120 | 95 | 80 | 90 | 70 | 60 | 100 | 70 | 55 | 70 | 50 | 40 | 55 | 40 | 30 | ||

| 12 | 235 | 175 | 150 | 180 | 135 | 115 | 170 | 150 | 140 | 115 | 90 | 85 | 90 | 70 | 70 | ||

| 13.1 | 205 | 145 | 120 | 155 | 110 | 90 | 140 | 120 | 110 | 100 | 80 | 70 | 80 | 65 | 55 | ||

| 13.2 | 100 | 70 | 60 | 80 | 55 | 45 | 70 | 60 | 55 | 50 | 40 | 35 | 40 | 30 | 30 | ||

M900 Cutting Data • MDH.. • M Coating

| TN7525 | TN7535 | TN450 | TTM | TTR | |||||||||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||||||||||||||

| M900 | MDHX09T308 | – | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material

|

vc (m/min) | ||||||||||||||||

| M | 14.1 | 240 | 200 | 160 | 220 | 180 | 160 | 150 | 90 | 80 | 120 | 80 | 70 | 100 | 70 | 50 | |

| 14.2 | 190 | 160 | 135 | 180 | 150 | 135 | 130 | 80 | 70 | 90 | 60 | 55 | 80 | 50 | 40 | ||

| 14.3 | 140 | 120 | 100 | 130 | 110 | 100 | 100 | 65 | 55 | 65 | 50 | 40 | 60 | 40 | 30 | ||

| 14.4 | 120 | 100 | 80 | 110 | 90 | 80 | 75 | 45 | 40 | 60 | 40 | 35 | 50 | 35 | 25 | ||

M900 Cutting Data • MDH.. • K Coating

| TN5515 | THM | |||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | |||||

| M900 | MDHX09T308 | – | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| M900 | MDHW120408 | – | 0,10 | 0,12 | 0,14 | 0,10 | 0,12 | 0,14 |

| Material

|

vc (m/min) | |||||||

| K | 15 | 295 | 215 | 185 | 135 | 100 | 85 | |

| 16 | 225 | 170 | 145 | 100 | 80 | 70 | ||

| 17 | 250 | 185 | 150 | 120 | 90 | 75 | ||

| 18 | 185 | 110 | 80 | 85 | 60 | 40 | ||

| 19 | 255 | 150 | 120 | 120 | 75 | 50 | ||

| 20 | 195 | 125 | 90 | 95 | 60 | 40 | ||

M900 Cutting Data • MDH.. • N Coating

| THM | |||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | ||

| M900 | MDHX09T308 | – | 0,08 | 0,10 | 0,12 |

| M900 | MDHW120408 | – | 0,10 | 0,12 | 0,14 |

| Material

|

vc (m/min) | ||||

| N | 21 | 1000 | 750 | 600 | |

| 22 | 500 | 360 | 300 | ||

| 23 | 1000 | 750 | 600 | ||

| 24 | 800 | 600 | 500 | ||

| 25 | 500 | 350 | 250 | ||

| 27 | 400 | 250 | 180 | ||

| 28 | 300 | 180 | 120 | ||

M900 Cutting Data • MDH.. • S Coating

| TN5515 | THM | |||||||

| cutter | Insert Type | VDI 3323 | hm* (mm) | |||||

| M900 | MDHX09T308 | – | 0,05 | 0,08 | 0,10 | 0,06 | 0,08 | 0,10 |

| M900 | MDHW120408 | – | 0,07 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 |

| Material

|

vc (m/min) | |||||||

| S | 31 | 48 | 36 | 30 | 36 | 28 | 24 | |

| 32 | 40 | 30 | 25 | 30 | 23 | 20 | ||

| 33 | 32 | 24 | 20 | 24 | 19 | 16 | ||

| 34 | 26 | 19 | 14 | 20 | 15 | 12 | ||

| 35 | 26 | 19 | 14 | 20 | 15 | 12 | ||

| 36 | – | – | – | 80 | 50 | 40 | ||

| 37 | – | – | – | 70 | 46 | 35 | ||