Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao, User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account

Modifica account

Ship To Account

Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

-

Notifications

Mark all as read - Modifica password

- Il mio profilo

- Disconnetti

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso.

Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione: {{SolutionName}}- Prodotti

- /

- Sgrossatori • Serie 4U70 • Smusso • Sistema metrico

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

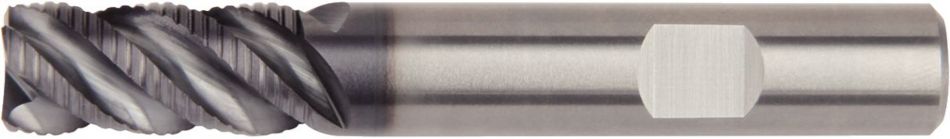

Sgrossatori • Serie 4U70 • Smusso • Sistema metrico

Serie 4U70 • Sistema metrico

Features and benefits

- Taglio centrale.

- Diversi numeri di denti in base al diametro.

- Spaziatura dei vani irregolare.

- Prodotti standard elencati. Modelli e rivestimenti aggiuntivi su ordinazione.

Uses and application

Fresatura in rampa: Grezzo

Scanalatura: Testa piana

Contornatura/fresatura a spallamento: Testa piana

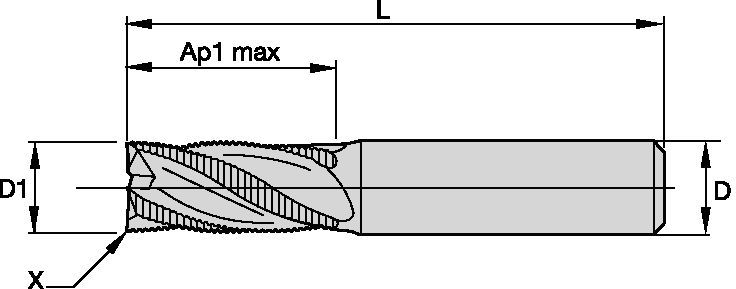

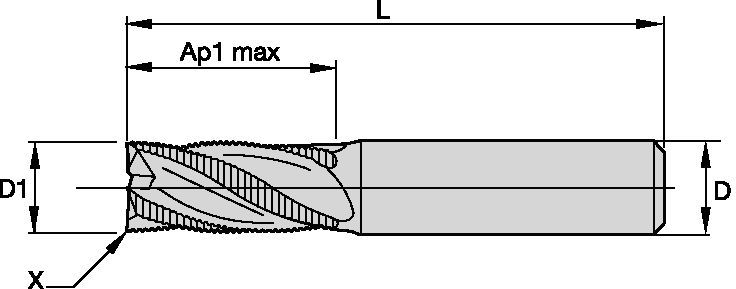

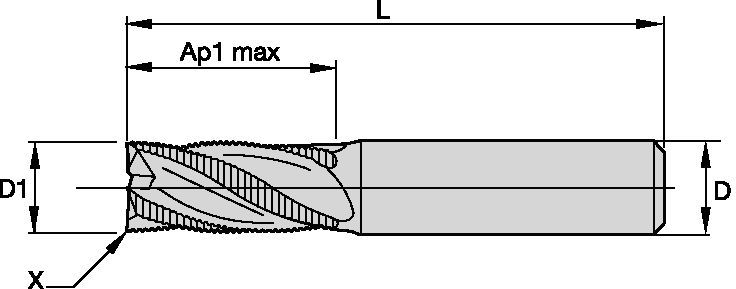

Dimensioni utensile: Configurazione del vano: X (variabile)

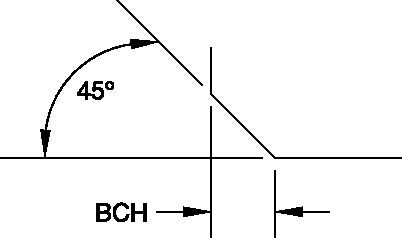

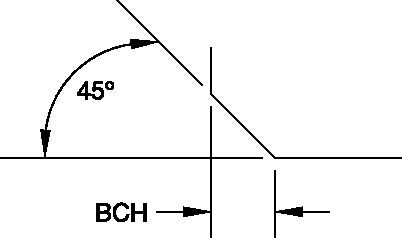

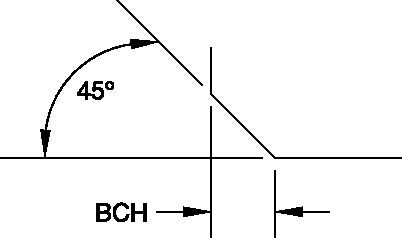

Corner Style: Corner Chamfer

Codolo — Cilindrico liscio

Codolo — Cilindrico Weldon

Angolo elica: 45°

Dati tecnici • Serie 4U70 • Sistema metrico

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||

| Side Milling (A) and Slotting (B) | WP15PE | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||

| A | B | Cutting Speed

|

D1

|

||||||||||||

| Material

|

ap | ae | ap | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 3 | 1 x D | 0,5 x D | 0,75 x D | 120 | – | 160 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 4 | 1 x D | 0,3 x D | 0,75 x D | 90 | – | 150 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 | |

| 5 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 100 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 6 | 1 x D | 0,3 x D | 0,3 x D | 50 | – | 75 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| M | 1 | 1 x D | 0,5 x D | 0,75 x D | 90 | – | 115 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 80 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 3 | 1 x D | 0,5 x D | 0,75 x D | 60 | – | 70 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| K | 1 | 1 x D | 0,5 x D | 1 x D | 120 | – | 150 | fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 2 | 1 x D | 0,5 x D | 1 x D | 110 | – | 140 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 3 | 1 x D | 0,5 x D | 1 x D | 110 | – | 130 | fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| S | 1 | 1 x D | 0,3 x D | 0,75 x D | 50 | – | 90 | fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 3 | 1 x D | 0,4 x D | 0,75 x D | 25 | – | 40 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 4 | 1 x D | 0,4 x D | 0,75 x D | 50 | – | 60 | fz | 0,026 | 0,037 | 0,045 | 0,052 | 0,064 | 0,074 | 0,084 | |

| H | 1 | 1 x D | 0,3 x D | 0,3 x D | 80 | – | 140 | fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 |

| 2 | 1 x D | 0,2 x D | 0,2 x D | 70 | – | 120 | fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| 3 | 1 x D | 0,2 x D | 0,2 x D | 60 | – | 90 | fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |