Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao, User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account

Modifica account

Ship To Account

Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

-

Notifications

Mark all as read - Modifica password

- Il mio profilo

- Disconnetti

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso.

Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i

aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione: {{SolutionName}}- Prodotti

- /

- Fresatura a fissaggio meccanico

- /

- Frese a spallamento a 0°/90°

- /

- Serie VSM11

- /

- VSM11 Series - Tool Bodies

- /

- VSM11™ • Frese a candela Weldon® • Sistema metrico

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

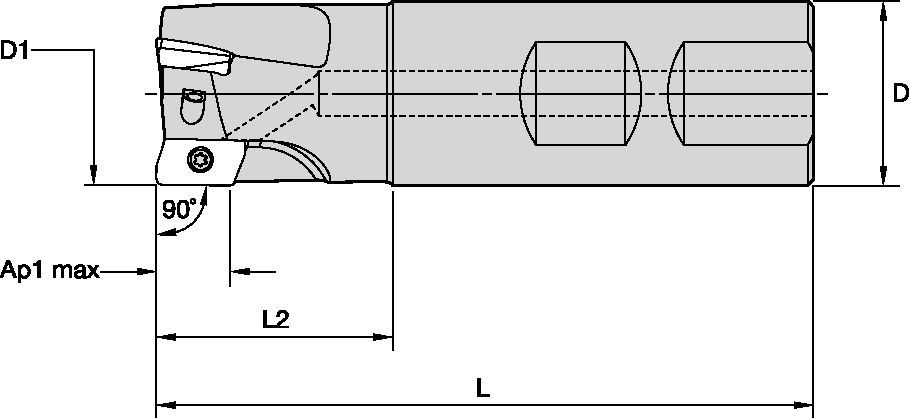

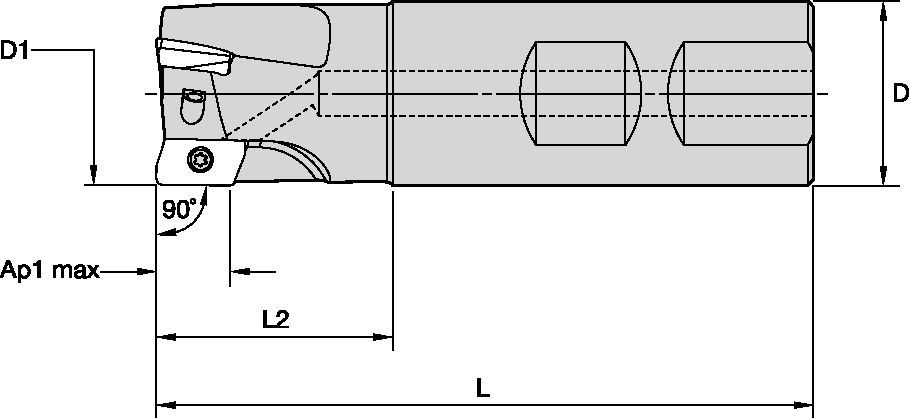

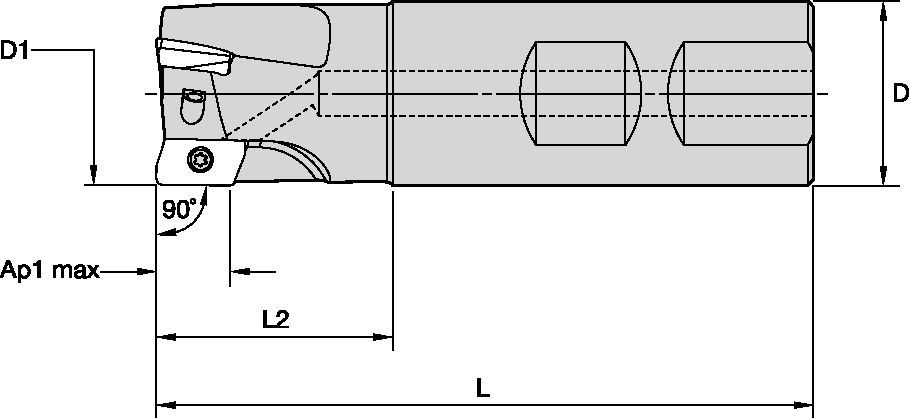

VSM11™ • Frese a candela Weldon® • Sistema metrico

Frese a candela Weldon® • Sistema metrico

Features and benefits

- Capacità di 90° effettivi.

- Maggiori capacità di fresatura in rampa.

- Maggiori capacità di finitura superficiale e del fianco.

- Efficace adduzione interna di refrigerante, diretto con la massima precisione sul tagliente.

Uses and application

Spianatura

Fresatura a riccio

Fresatura in rampa: Grezzo

Scanalatura: Testa piana

Contornatura/fresatura a spallamento: Testa piana

Codolo — Cilindrico Weldon

Fresatura — Senza refrigerante

Fresatura di tasche

Guida alla selezione degli inserti

| Material

|

Light

|

General

|

Universal | Heavy

|

||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | XDCT-ML | WP40PM | XDPT-MM | WP40PM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| P3–P4 | XDCT-ML | WP40PM | XDPT-MM | WP40PM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| P5–P6 | XDPT-MM | WP25PM | XDPT-MM | WP35CM | XD..-MU | WU20PM | XDPT-MH | WP40PM |

| M1–M2 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| M3 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| K1–K2 | XDCT-ML | WK15CM | XDPT-MM | WK15CM | XD..-MU | WU20PM | XDPT-MH | WK15CM |

| K3 | XDCT-ML | WP35CM | XDPT-MM | WP35CM | XD..-MU | WU20PM | XDPT-MH | WP35CM |

| N1–N2 | XDCT-ALP | WN10HM | XDCT-ALP | WN25PM | – | – | XDCT-ALP | WN25PM |

| N3 | XDCW-PCD | WDN10U | XDCW-PCD | WDN10U | – | – | XDCW-PCD | WDN10U |

| S1–S2 | XDCT-ML | WP25PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| S3 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| S4 | XDCT-ML | WS40PM | XDPT-MM | WS40PM | XD..-MU | WU20PM | XDPT-MH | WS40PM |

| H1 | XDCT-ML | WP25PM | XDPT-MM | WP25PM | XD..-MU | WU20PM | XDPT-MU | WU20PM |

Avanzamenti iniziali consigliati [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..PCD | 0,12 | 0,18 | 0,29 | 0,08 | 0,13 | 0,21 | 0,06 | 0,10 | 0,16 | 0,06 | 0,09 | 0,14 | 0,05 | 0,08 | 0,12 | .F..PCD |

| .F..ALP | 0,12 | 0,22 | 0,31 | 0,08 | 0,16 | 0,23 | 0,06 | 0,12 | 0,17 | 0,06 | 0,10 | 0,15 | 0,05 | 0,10 | 0,14 | .F..ALP |

| .E..ML | 0,17 | 0,27 | 0,36 | 0,13 | 0,20 | 0,26 | 0,10 | 0,15 | 0,19 | 0,08 | 0,13 | 0,17 | 0,08 | 0,12 | 0,16 | .E..ML |

| .S..MM/.S..MU | 0,23 | 0,32 | 0,47 | 0,17 | 0,23 | 0,34 | 0,13 | 0,17 | 0,25 | 0,11 | 0,15 | 0,22 | 0,10 | 0,14 | 0,20 | .S..MM/.S..MU |

| .S..MH | 0,23 | 0,37 | 0,56 | 0,17 | 0,27 | 0,40 | 0,13 | 0,20 | 0,30 | 0,11 | 0,17 | 0,26 | 0,10 | 0,16 | 0,24 | .S..MH |

| Light

|

General

|

Heavy

|

Avanzamenti iniziali consigliati [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| .F..PCD | .005 | .007 | .011 | .003 | .005 | .008 | .003 | .004 | .006 | .002 | .003 | .005 | .002 | .003 | .005 | .F..PCD |

| .F..ALP | .005 | .009 | .013 | .003 | .006 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | .F..ALP |

| .E..ML | .007 | .011 | .014 | .005 | .008 | .010 | .004 | .006 | .008 | .003 | .005 | .007 | .003 | .005 | .006 | .E..ML |

| .S..MM/.S..MU | .009 | .013 | .019 | .007 | .009 | .013 | .005 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .008 | .S..MM/.S..MU |

| .S..MH | .009 | .014 | .022 | .007 | .010 | .016 | .005 | .008 | .012 | .004 | .007 | .010 | .004 | .006 | .009 | .S..MH |

| Light

|

General

|

Heavy

|

Velocità iniziali consigliate [m/min]*

| Material Group | WDN10U | WK15CM | WK15PM | WN10HM | WN25PM | WP25PM | |||||||||||||

| P | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 330 | 285 | 270 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 275 | 240 | 200 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 255 | 215 | 175 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 225 | 185 | 150 | |

| 5 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 185 | 170 | 150 | |

| 6 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 165 | 125 | 100 | |

| M | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 205 | 180 | 165 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 185 | 160 | 130 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 140 | 120 | 95 | |

| K | 1 | — | — | — | 420 | 385 | 340 | 270 | 245 | 215 | — | — | — | — | — | — | 230 | 205 | 185 |

| 2 | — | — | — | 335 | 295 | 275 | 210 | 190 | 175 | — | — | — | — | — | — | 180 | 160 | 150 | |

| 3 | — | — | — | 280 | 250 | 230 | 175 | 160 | 145 | — | — | — | — | — | — | 150 | 135 | 120 | |

| N | 1 | 4010 | 3505 | 2990 | — | — | — | — | — | — | 795 | 695 | 600 | 1075 | 945 | 875 | — | — | — |

| 2 | 1600 | 1495 | 1400 | — | — | — | — | — | — | 795 | 695 | 600 | 945 | 875 | 760 | — | — | — | |

| 3 | 1600 | 1495 | 1400 | — | — | — | — | — | — | 560 | 485 | 420 | 945 | 875 | 760 | — | — | — | |

| S | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 40 | 35 | 25 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 40 | 35 | 25 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 50 | 40 | 25 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 70 | 50 | 35 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 120 | 90 | 70 |

| Material Group | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WU35PM | |||||||||||||

| P | 1 | 455 | 395 | 370 | 295 | 260 | 245 | — | — | — | — | — | — | 330 | 290 | 270 | 260 | 230 | 215 |

| 2 | 280 | 255 | 230 | 250 | 215 | 180 | — | — | — | — | — | — | 275 | 250 | 200 | 220 | 190 | 160 | |

| 3 | 255 | 230 | 205 | 230 | 195 | 160 | — | — | — | — | — | — | 255 | 220 | 175 | 200 | 170 | 140 | |

| 4 | 190 | 175 | 160 | 205 | 170 | 135 | — | — | — | — | — | — | 225 | 190 | 150 | 180 | 150 | 120 | |

| 5 | 260 | 230 | 210 | 170 | 155 | 135 | — | — | — | 170 | 145 | 120 | 185 | 175 | 150 | 150 | 135 | 120 | |

| 6 | 160 | 135 | 110 | 150 | 115 | 90 | — | — | — | 150 | 110 | 80 | 165 | 130 | 100 | 130 | 100 | 80 | |

| M | 1 | 205 | 185 | 155 | 195 | 170 | 155 | 225 | 200 | 185 | 210 | 170 | 140 | 205 | 180 | 165 | 170 | 150 | 135 |

| 2 | 185 | 160 | 140 | 175 | 150 | 125 | 205 | 180 | 145 | 180 | 145 | 120 | 185 | 160 | 130 | 155 | 130 | 110 | |

| 3 | 145 | 130 | 115 | 130 | 115 | 90 | 155 | 135 | 105 | 145 | 110 | 85 | 140 | 120 | 95 | 115 | 100 | 80 | |

| K | 1 | 295 | 265 | 240 | — | — | — | — | — | — | — | — | — | 250 | 220 | 185 | — | — | — |

| 2 | 235 | 210 | 190 | — | — | — | — | — | — | — | — | — | 200 | 180 | 150 | — | — | — | |

| 3 | 195 | 175 | 160 | — | — | — | — | — | — | — | — | — | 180 | 150 | 120 | — | — | — | |

| N | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 550 | 470 | 400 | — | — | — |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | 550 | 470 | 400 | — | — | — | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | 400 | 350 | 300 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 45 | 40 | 30 | 40 | 35 | 25 | 40 | 35 | 25 | 35 | 30 | 25 |

| 2 | — | — | — | — | — | — | 45 | 40 | 30 | 40 | 35 | 25 | 40 | 35 | 25 | 35 | 30 | 25 | |

| 3 | — | — | — | — | — | — | 55 | 45 | 30 | 50 | 40 | 25 | 50 | 40 | 25 | 45 | 35 | 25 | |

| 4 | — | — | — | — | — | — | 70 | 60 | 40 | 60 | 50 | 30 | 70 | 50 | 35 | 60 | 45 | 30 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 110 | 80 | 70 | — | — | — |

Velocità iniziali consigliate [SFM]

| Material Group | WDN10U | WK15CM | WK15PM | WN10HM | WN25PM | WP25PM | |||||||||||||

| P | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 1085 | 935 | 885 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 900 | 785 | 655 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 835 | 705 | 575 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 740 | 605 | 490 | |

| 5 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 605 | 560 | 490 | |

| 6 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 540 | 410 | 330 | |

| M | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 675 | 590 | 540 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 605 | 525 | 425 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 460 | 395 | 310 | |

| K | 1 | — | — | — | 1380 | 1265 | 1115 | 885 | 805 | 705 | — | — | — | — | — | — | 755 | 675 | 605 |

| 2 | — | — | — | 1100 | 970 | 900 | 690 | 625 | 575 | — | — | — | — | — | — | 590 | 525 | 490 | |

| 3 | — | — | — | 920 | 820 | 755 | 575 | 525 | 475 | — | — | — | — | — | — | 490 | 445 | 395 | |

| N | 1 | 13155 | 11500 | 9810 | — | — | — | — | — | — | 2605 | 2275 | 1965 | 3525 | 3100 | 2870 | — | — | — |

| 2 | 5250 | 4905 | 4595 | — | — | — | — | — | — | 2605 | 2275 | 1965 | 3100 | 2870 | 2495 | — | — | — | |

| 3 | 5250 | 4905 | 4595 | — | — | — | — | — | — | 1835 | 1590 | 1375 | 3100 | 2870 | 2495 | — | — | — | |

| S | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 130 | 115 | 80 |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 130 | 115 | 80 | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 165 | 130 | 80 | |

| 4 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 230 | 165 | 115 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 395 | 295 | 230 |

| Material Group | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WU35PM | |||||||||||||

| P | 1 | 1495 | 1295 | 1215 | 970 | 855 | 805 | — | — | — | — | — | — | 1080 | 950 | 885 | 855 | 755 | 705 |

| 2 | 920 | 835 | 755 | 820 | 705 | 590 | — | — | — | — | — | — | 900 | 820 | 655 | 720 | 625 | 525 | |

| 3 | 835 | 755 | 675 | 755 | 640 | 525 | — | — | — | — | — | — | 835 | 720 | 570 | 655 | 560 | 460 | |

| 4 | 625 | 575 | 525 | 675 | 560 | 445 | — | — | — | — | — | — | 735 | 620 | 490 | 590 | 490 | 395 | |

| 5 | 855 | 755 | 690 | 560 | 510 | 445 | — | — | — | 560 | 475 | 395 | 605 | 570 | 490 | 490 | 445 | 395 | |

| 6 | 525 | 445 | 360 | 490 | 375 | 295 | — | — | — | 490 | 360 | 260 | 540 | 425 | 325 | 425 | 330 | 260 | |

| M | 1 | 675 | 605 | 510 | 640 | 560 | 510 | 740 | 655 | 605 | 690 | 560 | 460 | 670 | 590 | 540 | 560 | 490 | 445 |

| 2 | 605 | 525 | 460 | 575 | 490 | 410 | 675 | 590 | 475 | 590 | 475 | 395 | 605 | 520 | 425 | 510 | 425 | 360 | |

| 3 | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 445 | 345 | 475 | 360 | 280 | 455 | 390 | 310 | 375 | 330 | 260 | |

| K | 1 | 970 | 870 | 785 | — | — | — | — | — | — | — | — | — | 820 | 720 | 605 | — | — | — |

| 2 | 770 | 690 | 625 | — | — | — | — | — | — | — | — | — | 655 | 590 | 490 | — | — | — | |

| 3 | 640 | 575 | 525 | — | — | — | — | — | — | — | — | — | 590 | 490 | 390 | — | — | — | |

| N | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 1800 | 1540 | 1310 | — | — | — |

| 2 | — | — | — | — | — | — | — | — | — | — | — | — | 1800 | 1540 | 1310 | — | — | — | |

| 3 | — | — | — | — | — | — | — | — | — | — | — | — | 1310 | 1145 | 980 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 150 | 130 | 100 | 130 | 115 | 80 | 130 | 110 | 80 | 115 | 100 | 80 |

| 2 | — | — | — | — | — | — | 150 | 130 | 100 | 130 | 115 | 80 | 130 | 110 | 80 | 115 | 100 | 80 | |

| 3 | — | — | — | — | — | — | 180 | 150 | 100 | 165 | 130 | 80 | 160 | 130 | 80 | 150 | 115 | 80 | |

| 4 | — | — | — | — | — | — | 230 | 195 | 130 | 195 | 165 | 100 | 225 | 160 | 110 | 195 | 150 | 100 | |

| H | 1 | — | — | — | — | — | — | — | — | — | — | — | — | 360 | 260 | 225 | — | — | — |