Prodotto simile a :

M95 SN12L5 IN SNHX

Inserti

Material Number2021926

ISO Catalog ID123506602ANSI Catalog ID123506602

- P Acciaio

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2021926 |

| ISO Catalog ID | 123506602 |

| ANSI Catalog ID | 123506602 |

| Qualità | TTM09 |

| Taglienti per inserto | 4 |

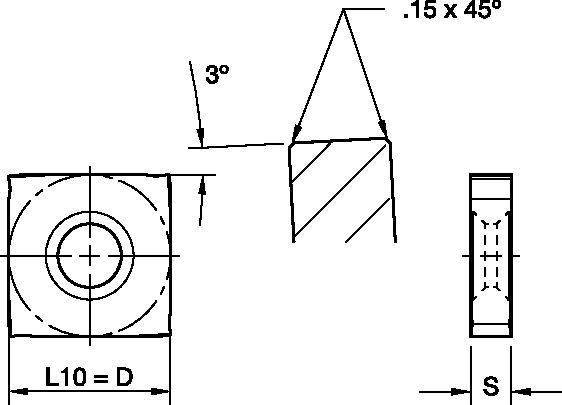

| [D] Dimensione IC inserto | 12.7 mm |

| [D] Dimensione IC inserto | 0.5 in |

| [L10] Lunghezza del tagliente dell’inserto | 12.7 mm |

| [L10] Lunghezza del tagliente dell’inserto | 0.5 in |

| [S] Spessore inserto | 5.4 mm |

| [S] Spessore inserto | 0.2126 in |

| Spessore medio del truciolo [HM] | 0.08 mm |

| Spessore medio del truciolo [HM] | 0.0031 in |

Materiale da lavorare

- Acciaio

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Feeds

Avanzamenti iniziali consigliati [mm]

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % di ingaggio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| SNHX | 0,12 | 0,28 | 0,71 | 0,08 | 0,20 | 0,51 | 0,06 | 0,15 | 0,38 | 0,06 | 0,13 | 0,33 | 0,05 | 0,12 | 0,30 | SNHX |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

Speeds

Velocità iniziali consigliate [m/min]

| Gruppo materiali | WK15CM | WP35CM | WP40PM | |||||||

| P | 0 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 |

| 1 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 | |

| 2 | – | – | – | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | – | – | – | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | – | – | – | 190 | 175 | 160 | 205 | 170 | 135 | |

| 5 | – | – | – | 260 | 230 | 210 | 170 | 155 | 135 | |

| 6 | – | – | – | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 420 | 385 | 340 | 295 | 265 | 240 | – | – | – |

| 2 | 335 | 295 | 275 | 235 | 210 | 190 | – | – | – | |

| 3 | 280 | 250 | 230 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | 66 | 50 | 33 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

Insert Selection

Guida alla selezione degli inserti

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| Geometria | Qualità | Geometria | Qualità | Geometria | Qualità | |

| P1–P2 | SNHX | WP40PM | SNHX | WP40PM | SNHX | WP40PM |

| P3–P4 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| P5–P6 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| M1–M2 | SNHX | WP40PM | SNHX | WP40PM | SNHX | WP40PM |

| M3 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| K1–K2 | SNHX | WK15CM | SNHX | WK15CM | SNHX | WK15CM |

| K3 | SNHX | WP35CM | SNHX | WP35CM | SNHX | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use