欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称: {{SolutionName}}Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

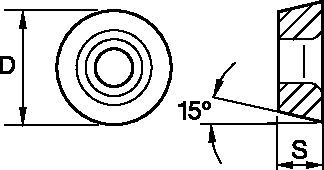

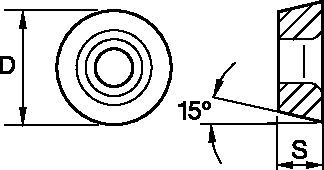

M170 • RDPX-MH • RD1003..

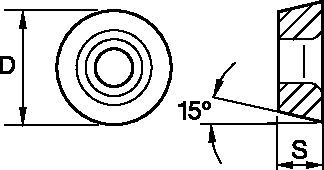

iC10 • 刀片

Features and benefits

- -MH 槽型是重型加工应用的首选。

- 适合高强度钢、铸铁材料和难加工材料的加工。

刀片选择指南

| Light

|

General

|

Heavy

|

||||

| Material

|

Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | MM | TN6525 | MM | TN6525 | MM | TN6540 |

| P3–P4 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| P5–P6 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| M1–M2 | – | – | MM | TN6525 | MM | TN6540 |

| M3 | – | – | MM | TN6525 | MM | TN6540 |

| K1–K2 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| K3 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | MM | TN6540 | – | – |

| S3 | – | – | MM | TN6540 | – | – |

| S4 | – | – | MM | TN6540 | – | – |

| H1 | MH | TN2505 | MH | TN2505 | – | – |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| MM | 0,28 | 0,41 | 0,74 | 0,20 | 0,29 | 0,53 | 0,15 | 0,22 | 0,4 | 0,13 | 0,19 | 0,35 | 0,12 | 0,18 | 0,32 | MM |

| MH | 0,33 | 0,58 | 0,98 | 0,24 | 0,42 | 0,71 | 0,18 | 0,32 | 0,53 | 0,16 | 0,28 | 0,46 | 0,14 | 0,25 | 0,42 | MH |

| Light

|

General

|

Heavy

|

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| MM | 0,35 | 0,51 | 0,93 | 0,25 | 0,37 | 0,67 | 0,19 | 0,28 | 0,50 | 0,17 | 0,24 | 0,44 | 0,15 | 0,22 | 0,40 | MM |

| MH | 0,42 | 0,73 | 1,23 | 0,30 | 0,53 | 0,88 | 0,23 | 0,39 | 0,66 | 0,20 | 0,34 | 0,57 | 0,18 | 0,32 | 0,53 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| MM | 0,47 | 0,68 | 1,25 | 0,34 | 0,49 | 0,89 | 0,25 | 0,37 | 0,67 | 0,22 | 0,32 | 0,58 | 0,20 | 0,29 | 0,53 | MM |

| MH | 0,56 | 0,98 | 1,66 | 0,40 | 0,71 | 1,18 | 0,30 | 0,53 | 0,88 | 0,26 | 0,46 | 0,76 | 0,24 | 0,42 | 0,70 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| MM | 0,64 | 0,94 | 1,73 | 0,46 | 0,68 | 1,24 | 0,35 | 0,51 | 0,92 | 0,30 | 0,44 | 0,80 | 0,28 | 0,40 | 0,73 | MM |

| MH | 0,77 | 1,36 | 2,31 | 0,55 | 0,97 | 1,63 | 0,41 | 0,73 | 1,21 | 0,36 | 0,63 | 1,05 | 0,33 | 0,58 | 0,96 | MH |

建议的初始速度 [米/分钟]

| Material Group | TN2505 | TN6525 | TN6540 | |||||||

| P | 1 | 550 | 420 | 360 | 410 | 320 | 280 | 360 | 280 | 240 |

| 2 | 320 | 240 | 205 | 320 | 250 | 215 | 250 | 190 | 170 | |

| 3 | 320 | 240 | 205 | 280 | 215 | 185 | 215 | 170 | 140 | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | |

| K | 1 | 400 | 300 | 250 | 275 | 245 | 220 | 220 | 205 | 180 |

| 2 | 540 | 365 | 280 | 215 | 190 | 180 | 175 | 155 | 140 | |

| 3 | 310 | 190 | 155 | 180 | 160 | 145 | 155 | 145 | 125 | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | |

| H | 1 | 175 | 140 | 95 | – | – | – | – | – | – |

| 2 | 175 | 140 | 95 | – | – | – | – | – | – | |

| 3 | 140 | 115 | 80 | – | – | – | – | – | – | |