- N 非铁材质

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 5358408 |

| 公制样本编号 | SDR100031E1W4 |

| 英制样本编号 | SDR100031E1W4 |

| 材质 | WDN00U |

| 每个刀片的切削刃 | 1 |

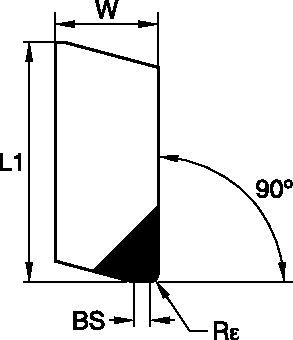

| [LI] 刀片长度 | 22.23 mm |

| [LI] 刀片长度 | 0.875 in |

| [BS] 刀尖刃口长度 | 1.52 mm |

| [BS] 刀尖刃口长度 | 0.06 in |

| [W] 刀片宽度 | 9.53 mm |

| [W] 刀片宽度 | 0.375 in |

| [Rε] 刀尖半径 | 0.8 mm |

| [Rε] 刀尖半径 | 0.031 in |

| 平均切屑厚度 [HM] | 0.02 mm |

| 平均切屑厚度 [HM] | 0.0008 in |

工件材料

- 非铁材质

Grades

WDN00U

钎焊到硬质合金基体上的超细晶粒金刚石刀尖 (PCD)。设计用于主要为有色金属材料的通用车削加工。应用于需要卓越表面光洁度的一系列连续至断续切削。用于低中硅含量的铝合金、非金属、铜、黄铜和锌基合金。超细晶粒金刚石颗粒尺寸可实现卓越的表面光洁度,同时确保任何 PCD 切削刀具都具有最佳机械抗冲击能力。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

建议的初始进给量 [毫米]

| ae/D1 = | 0,2 | 0,3 | 0,4 |

| fz 系数 | 1,5 | 1,3 | 1,0 |

| fz 系数 | 1,3 | 1,2 | 1,1 |

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SDR… | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | 0,05 | 0,10 | 0,20 | SDR… |

| EDR… | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | 0,05 | 0,10 | 0,20 | EDR… |

| 轻切削 | 中等切削 | 重切削 |

| ae/D1 = | 0,2 | 0,3 | 0,4 |

| fz 系数 | 1,5 | 1,3 | 1,0 |

| vc 系数 | 1,3 | 1,2 | 1,1 |

Recommended Starting Feeds [IPT]

| ae/D1 = | 0.2 | 0.3 | 0.4 |

| fz-Factor | 1.5 | 1.3 | 1.0 |

| vc-Factor | 1.3 | 1.2 | 1.1 |

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SDR… | .003 | .007 | .011 | .003 | .005 | .008 | .002 | .004 | .007 | .002 | .004 | .006 | .002 | .004 | .006 | SDR… |

| EDR… | .003 | .007 | .011 | .003 | .005 | .008 | .002 | .004 | .007 | .002 | .004 | .006 | .002 | .004 | .006 | EDR… |

| ae/D1 = | 0.2 | 0.3 | 0.4 |

| fz-Factor | 1.5 | 1.3 | 1.0 |

| vc-Factor | 1.3 | 1.2 | 1.1 |

Speeds

建议的初始速度 [米/分钟]

| ae/D1 = | 0,2 | 0,3 | 0,4 |

| fz 系数 | 1,5 | 1,3 | 1,0 |

| fz 系数 | 1,3 | 1,2 | 1,1 |

| ae/D1 = | 0,2 | 0,3 | 0,4 |

| fz 系数 | 1,5 | 1,3 | 1,0 |

| fz 系数 | 1,3 | 1,2 | 1,1 |

| 材料 分组 | WDN00U | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

Recommended Starting Speeds [SFM]

| ae/D1 = | 0.2 | 0.3 | 0.4 |

| fz-Factor | 1.5 | 1.3 | 1.0 |

| vc-Factor | 1.3 | 1.2 | 1.1 |

| 材料 分组 | WDN00U | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| ae/D1 = | 0.2 | 0.3 | 0.4 |

| fz-Factor | 1.5 | 1.3 | 1.0 |

| vc-Factor | 1.3 | 1.2 | 1.1 |

High Performance Combination Tools

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | SDR…/EDR… | WDN00U | SDR…/EDR… | WDN00U | SDR…/EDR… | WDN00U |

| N3 | SDR…/EDR… | WDN00U | SDR…/EDR… | WDN00U | SDR…/EDR… | WDN00U |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use