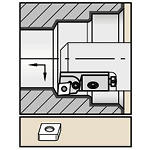

P 型夹持 •用于反向刀片

筛选器

筛选器

查看以下位置的筛选器

MetricInch

工件材料

工件材料

- P 钢 (1)

- P0低碳钢,长切屑 C < .25%;<125 HB;<530 N/mm^2 UTS(1)

- P1低碳钢、短切屑 C < .25%;<125 HB;<530 N/mm^2 UTS(1)

- P2中碳钢和高碳钢 C < .25%;<220 HB;<25 HRC;>530 N/mm^2 UTS(1)

- P3合金钢和工具钢 C > .25%;<330 HB;<35 HRC;600-850 N/mm^2 UTS(1)

- P4合金钢和工具钢 C > .25%;350-420 HB;35-43 HRC;850-1400 N/mm^2 UTS(1)

- P5铁素体、马氏体和 PH 不锈钢 <330 HB;<35 HRC;600-900 N/mm^2 UTS(1)

- P6高强度铁素体、马氏体和 PH 不锈钢 350-450 HB;35-43 HRC;900-2400 N/mm^2 UTS(1)

- M 不锈钢 (1)

- M1奥氏体不锈钢 130-200 HB;<600 N/mm^2 UTS(1)

- M2高强度奥氏体不锈钢和铸造不锈钢 150-230 HB;<25 HRC; >600 N/mm^2 UTS(1)

- M3双相不锈钢 135-275 HB;<30 HRC; 500-1200 N/mm^2 UTS(1)

- K 铸铁 (1)

- K1灰口铸铁 120-290 HB;<32 HRC; 125-500 N/mm^2 UTS(1)

- K2中低强度 CGI 和球墨铸铁 130-260 HB;<28 HRC; <600 N/mm^2 UTS(1)

- K3高强度球墨铸铁和奥氏体球墨铸铁 180-350 HB;<43 HRC; >600 N/mm^2 UTS(1)

- N 非铁金属材料 (1)

- N1铝型材 (1)

- N2低硅铝合金和镁合金 硅 < 12.2%(1)

- N3高硅铝合金 硅 > 12.2%(1)

- N4可机加工转位范围为 70 到 100 的铜基、黄铜基、锌基 (1)

- N5尼龙、塑料、橡胶、酚醛塑料、树脂、玻璃纤维 (1)

- N6碳、石墨复合材料、CFRP (1)

- N7MMC (1)

- S 高温合金 (1)

- S1铁基耐热合金 160-260 HB;25-48 HRC;500-1200 N/mm^2 UTS(1)

- S2钴基耐热合金 250-450 HB;25-48 HRC;1000-1450 N/mm^2 UTS(1)

- S3镍基耐热合金 160-450 HB;<48 HRC; 600-1700 N/mm^2 UTS(1)

- S4钛和钛合金 300-400 HB;33-43 HRC;900-1600 N/mm^2 UTS(1)

- H 淬火材料 (1)

- H1淬火材料 44-48 HRC(1)

- H2淬火材料 48-55 HRC(1)

- H3淬火材料 56-60 HRC(1)

- H4淬火材料 >60 HRC(1)

应用

应用

CRT Profiling (1)

ID Facing (1)

Multiple Direction Cutting (1)

切削条件

切削条件

- Heavily Interrupted Cut (1)

- Lightly Interrupted Cut (1)

- Smooth Cut (1)

刀尖半径

刀尖半径

- 0.1 mm(1)

- 0.2 mm(1)

- 0.4 mm(1)

- 0.8 mm(1)

- 1.2 mm(1)

- 1.6 mm(1)

到

application

切削刀具材质

切削刀具材质

- CW2015 (1)

- CW5025 (1)

- PB100 (1)

- THM (1)

- THM-X (1)

- THMF-X (1)

- TN10P (1)

- TN10U (1)

- TN15M (1)

- TN15U (1)

- TN2000 (1)

- TN20K (1)

- TN20P (1)

- TN30M (1)

- TN30P (1)

- TN4000 (1)

- TN6010 (1)

- TTS (1)

- WBH10P (1)

- WBH10U (1)

- WBH20P (1)

- WBH30P (1)

- WDN00U (1)

- WDN25U (1)

- WK05CT (1)

- WK15CT (1)

- WK20CT (1)

- WM15CT (1)

- WM25CT (1)

- WM35CT (1)

- WP05CT (1)

- WP15CT (1)

- WP25CT (1)

- WP35CT (1)

- WS10PT (1)

- WS25PT (1)

- WU10HT (1)

- WU10PT (1)

- WU25PT (1)

insertGeometry

切削刀具材料

切削刀具材料

- B H (1)

- B L (1)

- C A (1)

- C N (1)

- D P (1)

- H W (1)

No filters matching ""