TopThread™ - Toolholders

筛选器

筛选器

查看以下位置的筛选器

MetricInch

工件材料

工件材料

- P 钢 (98)

- P0低碳钢,长切屑 C < .25%;<125 HB;<530 N/mm^2 UTS(98)

- P1低碳钢、短切屑 C < .25%;<125 HB;<530 N/mm^2 UTS(98)

- P2中碳钢和高碳钢 C < .25%;<220 HB;<25 HRC;>530 N/mm^2 UTS(98)

- P3合金钢和工具钢 C > .25%;<330 HB;<35 HRC;600-850 N/mm^2 UTS(98)

- P4合金钢和工具钢 C > .25%;350-420 HB;35-43 HRC;850-1400 N/mm^2 UTS(98)

- P5铁素体、马氏体和 PH 不锈钢 <330 HB;<35 HRC;600-900 N/mm^2 UTS(98)

- P6高强度铁素体、马氏体和 PH 不锈钢 350-450 HB;35-43 HRC;900-2400 N/mm^2 UTS(98)

- M 不锈钢 (98)

- M1奥氏体不锈钢 130-200 HB;<600 N/mm^2 UTS(98)

- M2高强度奥氏体不锈钢和铸造不锈钢 150-230 HB;<25 HRC; >600 N/mm^2 UTS(98)

- M3双相不锈钢 135-275 HB;<30 HRC; 500-1200 N/mm^2 UTS(98)

- K 铸铁 (98)

- K1灰口铸铁 120-290 HB;<32 HRC; 125-500 N/mm^2 UTS(98)

- K2中低强度 CGI 和球墨铸铁 130-260 HB;<28 HRC; <600 N/mm^2 UTS(98)

- K3高强度球墨铸铁和奥氏体球墨铸铁 180-350 HB;<43 HRC; >600 N/mm^2 UTS(98)

- N 非铁金属材料 (98)

- N1铝型材 (98)

- N2低硅铝合金和镁合金 硅 < 12.2%(98)

- N3高硅铝合金 硅 > 12.2%(98)

- N4可机加工转位范围为 70 到 100 的铜基、黄铜基、锌基 (98)

- N5尼龙、塑料、橡胶、酚醛塑料、树脂、玻璃纤维 (98)

- N6碳、石墨复合材料、CFRP (98)

- N7MMC (98)

- S 高温合金 (98)

- S1铁基耐热合金 160-260 HB;25-48 HRC;500-1200 N/mm^2 UTS(98)

- S2钴基耐热合金 250-450 HB;25-48 HRC;1000-1450 N/mm^2 UTS(98)

- S3镍基耐热合金 160-450 HB;<48 HRC; 600-1700 N/mm^2 UTS(98)

- S4钛和钛合金 300-400 HB;33-43 HRC;900-1600 N/mm^2 UTS(98)

- H 淬火材料 (96)

- H1淬火材料 44-48 HRC(96)

- H2淬火材料 48-55 HRC(96)

- H3淬火材料 56-60 HRC(90)

- H4淬火材料 >60 HRC(90)

Select All Star

- DE (3)

- IN (1)

- US (22)

应用

应用

Chamfer Turning (6)

Cut-Off (6)

Deep Grooving (6)

Face Grooving (73)

Facing (12)

Grooving (99)

ID Grooving (22)

ID Thread Turning (26)

Multiple Direction Cutting (6)

OD Thread Turning (99)

Plunge Turning (6)

Profiling (8)

TRN Boring (6)

Threading (93)

Turning (12)

螺纹类型

螺纹类型

- 60 (96)

- ACME (59)

- API (16)

- API RD (40)

- BSW (27)

- BUTTRESS (45)

- M (6)

- NPT (12)

- STUB ACME (40)

- UN (90)

- UNJ (27)

切削条件

切削条件

- Heavily Interrupted Cut (96)

- Lightly Interrupted Cut (96)

- Smooth Cut (96)

连接类型

连接类型

- KM (28)

- Toolholder (48)

每个刀片的切削刃

每个刀片的切削刃

- 1.0 (96)

- 2.0 (98)

到

总长 [L]

总长 [L]

- 40.0 mm(8)

- 47.0 mm(4)

- 63.5 mm(1)

- 70.0 mm(6)

- 80.0 mm(3)

- 88.9 mm(1)

- 90.0 mm(4)

- 100.0 mm(5)

- 101.6 mm(2)

- 110.0 mm(4)

- 114.3 mm(9)

- 125.0 mm(7)

- 127.0 mm(9)

- 150.0 mm(14)

- 152.4 mm(21)

- 170.0 mm(2)

到

刀尖半径

刀尖半径

- 0.025 mm(6)

- 0.05 mm(6)

- 0.075 mm(75)

- 0.1 mm(79)

- 0.125 mm(12)

- 0.15 mm(23)

- 0.175 mm(80)

- 0.2 mm(96)

- 0.225 mm(27)

- 0.25 mm(39)

- 0.275 mm(6)

- 0.3 mm(27)

- 0.325 mm(57)

- 0.35 mm(52)

- 0.4 mm(40)

- 0.45 mm(14)

- 0.475 mm(6)

- 0.5 mm(51)

- 0.575 mm(57)

- 0.75 mm(39)

- 0.775 mm(79)

- 0.9 mm(16)

- 1.0 mm(79)

- 1.2 mm(79)

- 1.25 mm(64)

- 1.5 mm(79)

- 1.575 mm(40)

- 1.6 mm(73)

- 1.75 mm(79)

- 1.975 mm(40)

- 2.0 mm(49)

- 2.25 mm(40)

- 2.4 mm(50)

- 2.5 mm(17)

- 3.175 mm(17)

到

application

最小切削深度

最小进给

切削刀具材质

切削刀具材质

- K313 (32)

- K420 (32)

- K68 (32)

- KB1630 (16)

- KBH20 (6)

- KC5010 (32)

- KC5025 (32)

- KC5410 (22)

- KC720 (32)

- KC730 (32)

- KC850 (32)

- KC9110 (2)

- KCK20 (24)

- KCK20B (32)

- KCP10B (32)

- KCP25B (32)

- KCP25C (32)

- KCU10 (32)

- KCU10B (32)

- KCU25 (32)

- KCU25B (32)

- KD1425 (12)

- KT315 (22)

- THM (79)

- TN6010 (96)

- TN6025 (98)

- WU10HT (21)

- WU10PT (33)

- WU25PT (19)

刀具手式

刀具手式

- L (30)

- R (46)

修光刃刀片

修光刃刀片

- N (98)

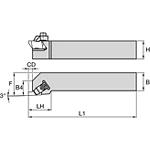

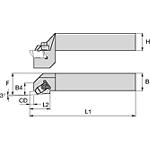

F 尺寸

F 尺寸

- 11.0 mm(6)

- 12.0 mm(1)

- 12.7 mm(3)

- 13.0 mm(2)

- 14.275 mm(1)

- 15.875 mm(3)

- 16.0 mm(2)

- 17.0 mm(8)

- 19.05 mm(1)

- 20.0 mm(1)

- 22.0 mm(4)

- 25.0 mm(3)

- 25.4 mm(6)

- 27.0 mm(8)

- 28.0 mm(1)

- 31.75 mm(13)

- 32.0 mm(7)

- 38.1 mm(4)

- 40.0 mm(2)

到

最小镗孔直径

最小镗孔直径

- 18.5 mm(2)

- 20.0 mm(4)

- 25.0 mm(2)

- 32.0 mm(4)

- 34.0 mm(4)

- 40.0 mm(4)

- 54.0 mm(2)

到

最小轴向凹槽直径

最小轴向凹槽直径

- 0.0 mm(52)

- 18.5 mm(2)

- 20.0 mm(4)

- 25.0 mm(2)

- 32.0 mm(4)

- 34.0 mm(4)

- 40.0 mm(4)

- 41.3 mm(25)

- 47.6 mm(25)

- 54.0 mm(6)

- 55.88 mm(1)

- 56.625 mm(2)

- 57.2 mm(12)

- 60.325 mm(1)

- 63.5 mm(4)

- 76.2 mm(1)

- 88.9 mm(28)

- 139.7 mm(25)

- 174.6 mm(25)

- 209.6 mm(12)

- 222.3 mm(12)

到

最大轴向凹槽直径

最大轴向凹槽直径

- 9999.0 mm(96)

到

切削方向

切削方向

- E (54)

- S (22)

前角样式

前角样式

- NEGATIVE-ZERO (1)

- NEUTRAL (ZERO) (75)

最大镗孔深度

最大镗孔深度

- 25.4 mm(7)

- 40.0 mm(6)

- 42.03 mm(2)

- 50.8 mm(13)

- 55.09 mm(4)

- 56.11 mm(2)

- 70.02 mm(2)

- 75.04 mm(4)

- 76.02 mm(2)

- 80.0 mm(2)

- 96.02 mm(2)

到

镗杆材料

镗杆材料

- C (2)

- S (20)

frontEnd

切削宽度

切削宽度

- 0.5 mm(39)

- 0.787 mm(39)

- 0.8 mm(39)

- 0.889 mm(8)

- 0.991 mm(16)

- 1.0 mm(79)

- 1.041 mm(31)

- 1.19 mm(43)

- 1.194 mm(71)

- 1.2 mm(79)

- 1.39 mm(16)

- 1.397 mm(8)

- 1.4 mm(39)

- 1.473 mm(39)

- 1.5 mm(79)

- 1.57 mm(56)

- 1.575 mm(79)

- 1.69 mm(8)

- 1.7 mm(39)

- 1.702 mm(16)

- 1.75 mm(79)

- 1.829 mm(40)

- 1.94 mm(8)

- 1.95 mm(39)

- 1.956 mm(8)

- 1.981 mm(40)

- 2.0 mm(79)

- 2.007 mm(16)

- 2.2 mm(79)

- 2.235 mm(20)

- 2.236 mm(21)

- 2.24 mm(16)

- 2.25 mm(58)

- 2.387 mm(21)

- 2.388 mm(79)

- 2.39 mm(19)

- 2.464 mm(12)

- 2.5 mm(79)

- 2.667 mm(12)

- 2.74 mm(8)

- 2.743 mm(8)

- 2.75 mm(79)

- 2.794 mm(12)

- 2.997 mm(20)

- 3.0 mm(90)

- 3.099 mm(12)

- 3.17 mm(40)

- 3.175 mm(96)

- 3.18 mm(16)

- 3.2 mm(50)

- 3.245 mm(39)

- 3.25 mm(25)

- 3.251 mm(6)

- 3.27 mm(8)

- 3.32 mm(6)

- 3.5 mm(90)

- 3.607 mm(12)

- 3.81 mm(8)

- 3.82 mm(23)

- 3.835 mm(8)

- 3.84 mm(39)

- 3.96 mm(25)

- 3.962 mm(40)

- 3.974 mm(6)

- 3.988 mm(12)

- 4.0 mm(57)

- 4.242 mm(4)

- 4.25 mm(27)

- 4.5 mm(57)

- 4.521 mm(12)

- 4.699 mm(12)

- 4.775 mm(44)

- 4.78 mm(2)

- 4.785 mm(2)

- 4.788 mm(8)

- 4.8 mm(40)

- 4.801 mm(57)

- 4.88 mm(21)

- 4.95 mm(12)

- 4.953 mm(21)

- 4.978 mm(40)

- 5.0 mm(17)

- 5.004 mm(2)

- 5.41 mm(4)

- 5.5 mm(11)

- 6.0 mm(10)

- 6.35 mm(17)

- 6.36 mm(8)

- 6.502 mm(4)

到

刀片尺寸

刀片尺寸

- 1 (1)

- 2 (41)

- 3 (42)

- 4 (14)

- 6 (1)

最大切削深度

最大切削深度

- 3.505 mm(12)

- 3.51 mm(23)

- 5.33 mm(16)

- 5.334 mm(20)

- 5.715 mm(1)

- 6.1 mm(1)

- 7.468 mm(8)

- 7.47 mm(7)

- 8.484 mm(2)

到

insertGeometry

切削刀具材料

切削刀具材料

- B H (16)

- B L (6)

- D P (12)

- H T (22)

- H W (98)

backEnd

连接类型

连接类型

- SQUARE SHANK (48)

- TAPER SHANK (28)

系统规格

系统规格

- KM40TS (28)

后端直径

后端直径

- 40.0 mm(32)

到

刀柄高度

刀柄高度

- 9.525 mm(1)

- 12.0 mm(2)

- 12.7 mm(4)

- 15.875 mm(3)

- 16.0 mm(2)

- 19.05 mm(6)

- 20.0 mm(4)

- 25.0 mm(7)

- 25.4 mm(12)

- 31.75 mm(5)

- 32.0 mm(2)

到

刀柄宽度

刀柄宽度

- 9.525 mm(1)

- 12.0 mm(2)

- 12.7 mm(4)

- 15.875 mm(3)

- 16.0 mm(2)

- 19.05 mm(6)

- 20.0 mm(4)

- 25.0 mm(7)

- 25.4 mm(13)

- 31.75 mm(4)

- 32.0 mm(2)

到

No filters matching ""