Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Herramientas de alto rendimiento ya a la venta.

Compre ahora.

WIDIA a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Produtos

- /

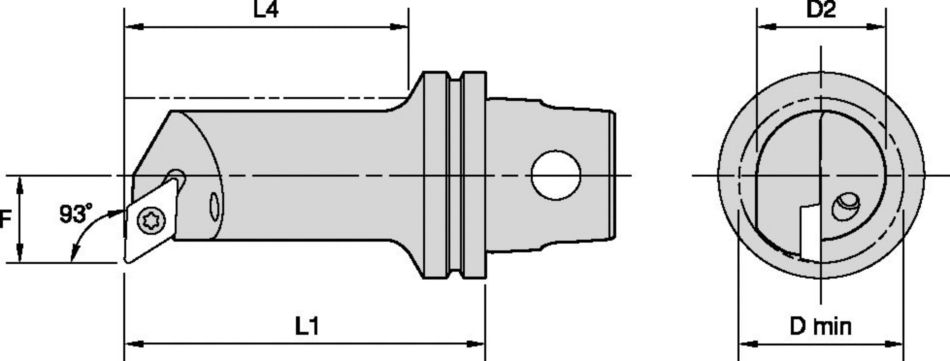

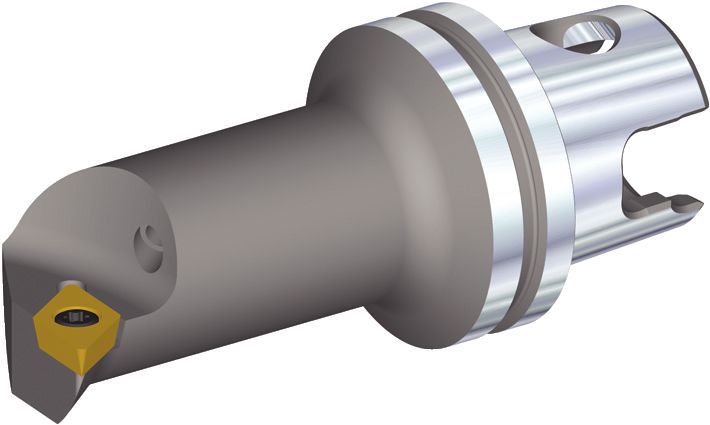

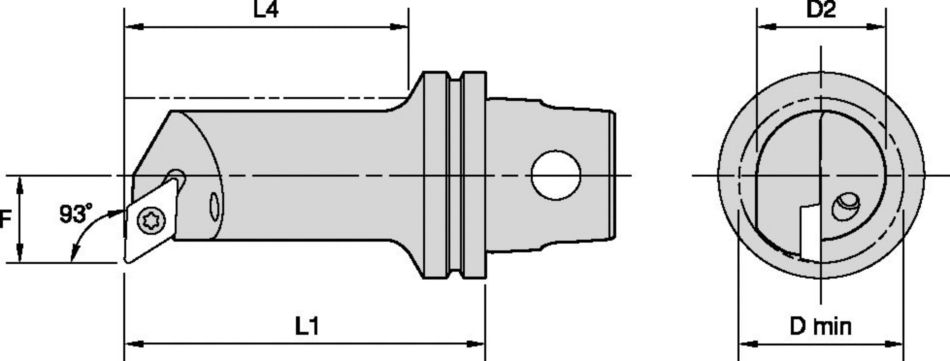

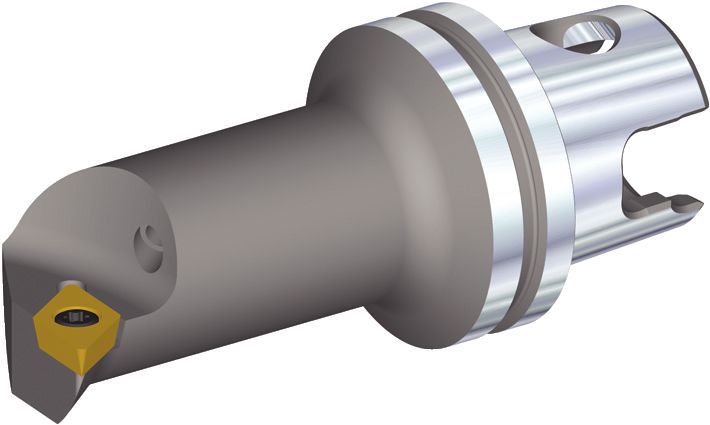

- SDUP 93° - Unidades de corte interno de acero KM32TS (plaquitas Sujeción S)

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

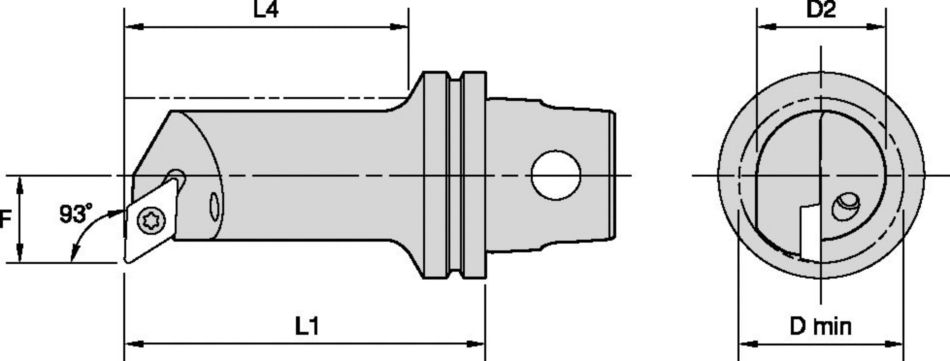

SDUP 93° - Unidades de corte interno de acero KM32TS (plaquitas Sujeción S)

Sujeción S

Uses and application

Shank - KM-TS ISO 26622

Mango — KM-TS ISO 26622

Coolant — Through Coolant 100 bar (1500 psi) Maximum

Refrigeración — Con refrigeración interna 100 bar (1500 psi) máximo