Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

WIDIA a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente Cambiar cuenta

Dirección de envío (#) Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

Notifications

Mark all as read- Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s) añadido correctamente al carrito

Ver carrito

Ver carrito

Herramientas de alto rendimiento ya a la venta. Compre ahora.

WIDIA a su servicio

Artículo(s) añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución:{{SolutionName}}- Produtos

- /

- Fresado intercambiable

- /

- Fresas de copiar

- /

- Serie M170

- /

- M170 Series - Inserts

- /

- RD07

- /

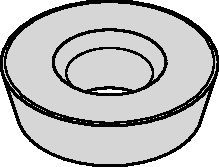

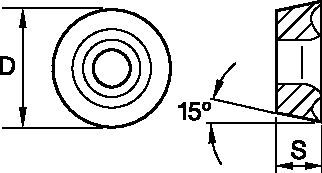

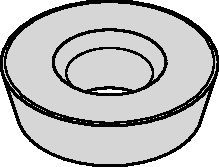

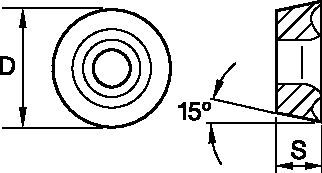

- M170 • RDPX-MH • RD0702..

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

M170 • RDPX-MH • RD0702..

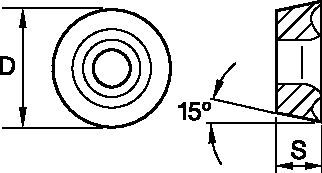

iC07 • Plaquitas

Features and benefits

- La geometría -MH es idónea para aceros de alta resistencia, fundición y mecanizado pesado.

Guía para la selección de plaquitas

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| P5–P6 | MH | TN2505 | MH | TN6525 | MH | TN6540 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| K3 | MH | TN2505 | MH | TN2505 | MH | TN6525 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | MH | TN2505 | MH | TN2505 | – | – |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MH | 0,23 | 0,46 | 0,74 | 0,17 | 0,33 | 0,54 | 0,13 | 0,25 | 0,40 | 0,11 | 0,22 | 0,35 | 0,10 | 0,20 | 0,32 | MH |

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MH | 0,28 | 0,56 | 0,91 | 0,20 | 0,41 | 0,65 | 0,15 | 0,31 | 0,49 | 0,13 | 0,27 | 0,43 | 0,12 | 0,24 | 0,39 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MH | 0,45 | 0,91 | 1,47 | 0,32 | 0,65 | 1,05 | 0,24 | 0,49 | 0,78 | 0,21 | 0,42 | 0,68 | 0,19 | 0,39 | 0,62 | MH |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| MH | 0,37 | 0,75 | 1,21 | 0,27 | 0,54 | 0,87 | 0,20 | 0,40 | 0,65 | 0,18 | 0,35 | 0,56 | 0,16 | 0,32 | 0,52 | MH |

Velocidades iniciales recomendadas [m/min]

| Material Group | TN2505 | TN6525 | TN6540 | |||||||

| P | 1 | 550 | 420 | 360 | 410 | 320 | 280 | 360 | 280 | 240 |

| 2 | 320 | 240 | 205 | 320 | 250 | 215 | 250 | 190 | 170 | |

| 3 | 320 | 240 | 205 | 280 | 215 | 185 | 215 | 170 | 140 | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | |

| K | 1 | 400 | 300 | 250 | 275 | 245 | 220 | 220 | 205 | 180 |

| 2 | 540 | 365 | 280 | 215 | 190 | 180 | 175 | 155 | 140 | |

| 3 | 310 | 190 | 155 | 180 | 160 | 145 | 155 | 145 | 125 | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | |

| H | 1 | 175 | 140 | 95 | – | – | – | – | – | – |

| 2 | 175 | 140 | 95 | – | – | – | – | – | – | |

| 3 | 140 | 115 | 80 | – | – | – | – | – | – | |