Produkt podobny do:

TOP DRILL do wiercenia głębokich otworów • 25 x D • TDD107 • 2 rowki

TDD107 • 25 x D • Metryczne

Nr materiału3899572

Nr katalogowy ISOTDD107Z08500Nr katalogowy ANSITDD107Z08500

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

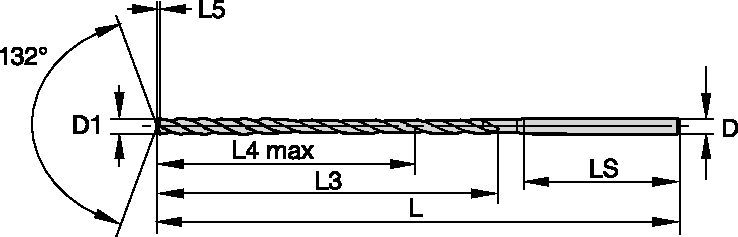

Tool Dimensions: 2flute/4margin/coolant

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 3899572 |

| Nr katalogowy ISO | TDD107Z08500 |

| Nr katalogowy ANSI | TDD107Z08500 |

| Grade | WU20PD |

| [D1] Drill Diameter M | 8.5 mm |

| [D1] Drill Diameter M | 0.3346 in |

| [D] Adapter / Shank / Bore Diameter | 9 mm |

| [D] Adapter / Shank / Bore Diameter | 0.3543 in |

| [L3] Flute Length | 238 mm |

| [L3] Flute Length | 9.3701 in |

| [L4] Maximum Drilling Depth | 219 mm |

| [L4] Maximum Drilling Depth | 8.622 in |

| [L5] Drill Point Length | 1.788 mm |

| [L5] Drill Point Length | 0.0704 in |

| [LS] Shank Length | 42 mm |

| [LS] Shank Length | 1.6535 in |

| [L] Overall Length | 290 mm |

| [L] Overall Length | 11.4173 in |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Zastosowania

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

Tool Dimensions: 2flute/4margin/coolant

Gatunki

WU20PD

Composition: With a multilayered PVD TiN-TiAlN coating, a high-quality, sub-micron, carbide substrate and a state-of-the-art surface condition, this grade gives the highest level of wear resistance at high cutting speeds.

Application: First choice for alloyed and high-alloyed steels and cast irons. A state-of-the-art surface condition enables superior chip evacuation even when MQL is applied.

Właściwości i zalety

- Standard items listed. Additional diameters and lengths made to order.

- For information about Custom Solutions, such as multi-step drills, see page [REFERENCE].

- For information about Reconditioning Services, see page [REFERENCE].

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Parametry skrawania

| Metryczne | |||

| tolerancja | |||

| zakres rozmiarów nominalnych | D1 tolerancja | D1 tolerancja | D tolerancja h6 |

| 0,000/–0,012 | 0,000/–0,008 | ||

| 0,000/–0,015 | 0,000/–0,009 | ||

| 0,000/–0,018 | 0,000/–0,011 | ||

Parametry skrawania • Seria TDD • WU20PD™ • Wewnętrzne doprowadzanie chłodziwa • Metryczne

| Calowe | |||

| tolerancja | |||

| D1 | D1 tolerancja m7 | D | D tolerancja h6 |

| .0000/-.0005 | .0000/-.0003 | ||

| .0000/-.0006 | .0000/-.0004 | ||

| .0000/-.0007 | .0000/-.0004 | ||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data