Produkt podobny do:

RNMG-RH • Obróbka zgrubna

RNMG-RH

Nr materiału4171530

Nr katalogowy ISORNMG090300RHNr katalogowy ANSIRNMG32RH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 4171530 |

| Nr katalogowy ISO | RNMG090300RH |

| Nr katalogowy ANSI | RNMG32RH |

| Grade | WP25CT |

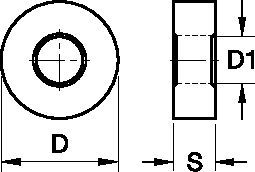

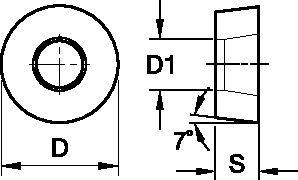

| [D] Insert IC Size | 9.525 mm |

| [D] Insert IC Size | 0.375 in |

| [S] Insert Thickness | 3.18 mm |

| [S] Insert Thickness | 0.125 in |

| [D1] Insert Hole Size | 3.81 mm |

| [D1] Insert Hole Size | 0.15 in |

Materiały przedmiotu obrabianego

- Steel

- Cast Iron

Gatunki

WP25CT

A tough cobalt-enriched carbide grade with a newly designed multilayer K-MTCVD TiCN-Al2O3-TiCNTiN coating with superior interlayer adhesion. This is the industry’s best general-purpose turning grade for most steels and ferritic and martensitic stainless steels. The substrate design, with cobalt-enrichment, ensures adequate deformation resistance along with excellent bulk toughness and insert edge strength. The coating layers offer good wear resistance over a wide range of machining conditions. The smoothness of the coating leads to reduced frictional heat, minimizes microchipping, and improves workpiece surface finishes.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data