Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Logout

Item(s) successfully added to cart

View Cart

View Cart

Buy More Inserts, Save More on Steel Shop Now

Contact a WIDIA Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Turning

- /

- O.D. and I.D. Turning

- /

- High Performance Inserts

- /

- Inserts For Machining Aluminum

- /

- DCGT-AL • Inserts for Aluminum

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

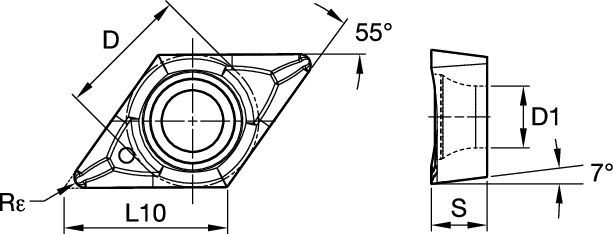

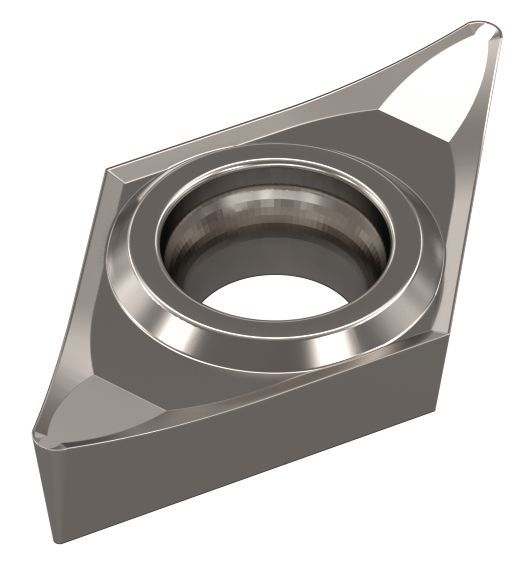

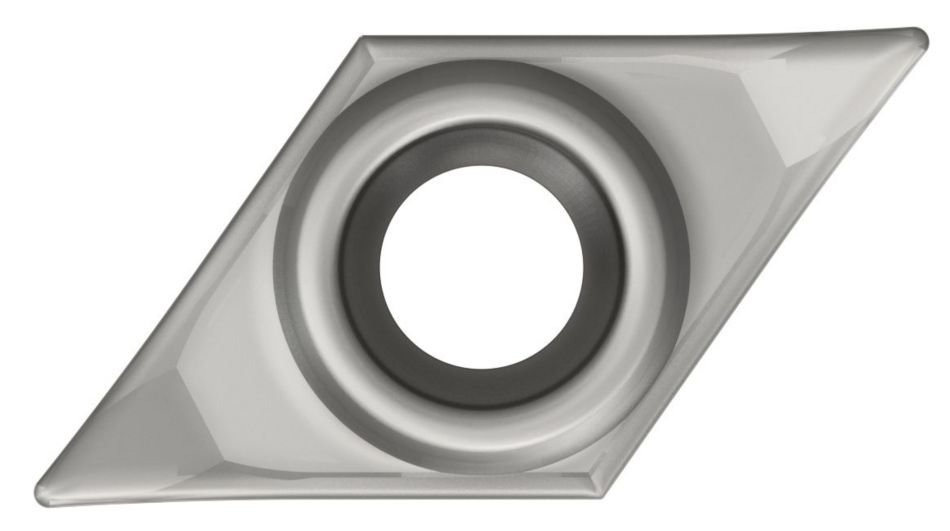

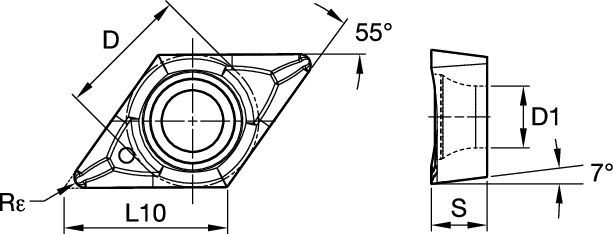

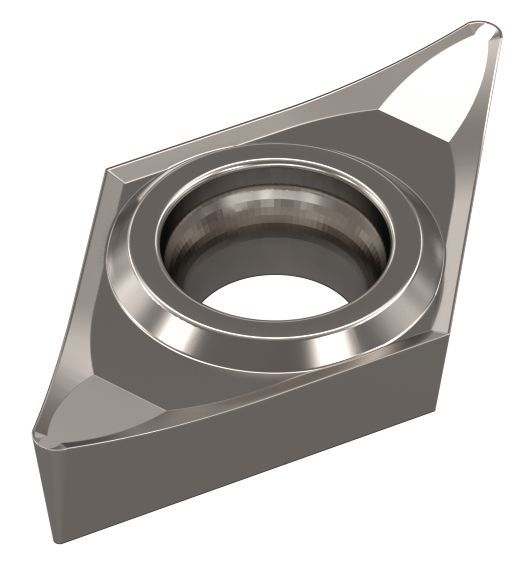

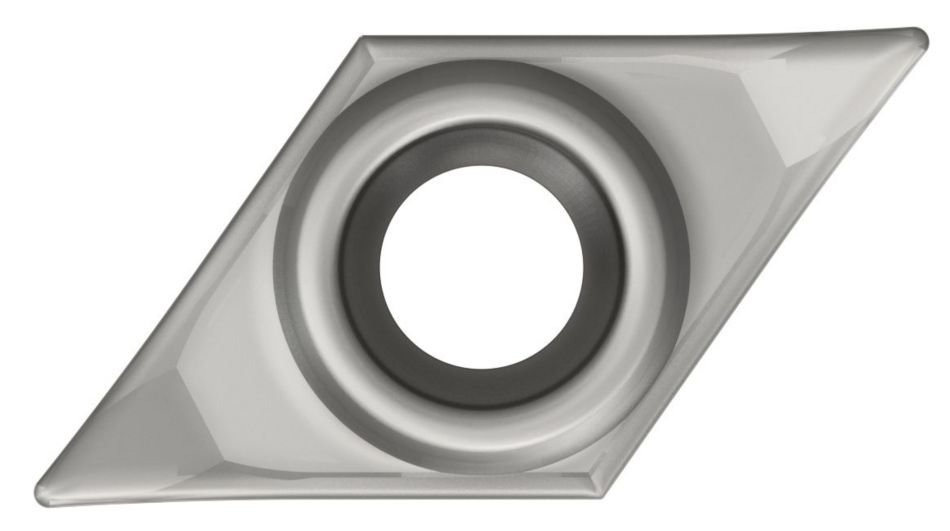

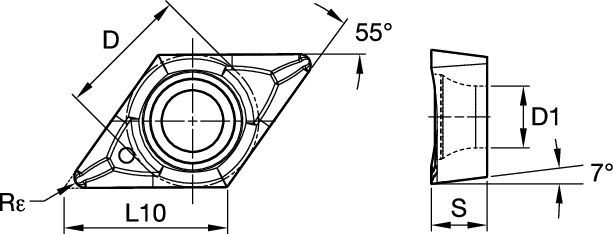

DCGT-AL • Inserts for Aluminum

WIDIA™ Inserts • DCGT-AL • Machining Aluminum

Features and benefits

- Universal geometry for aluminum and non-ferrous materials.

Uses and application

100788769

Turning

Profiling

Facing

Chamfering

Boring