Product Similar To:

VariMill™ Chip Splitters • Radiused • 7 Flutes • 5 x D • Weldon® Shank • Metric

High Performance Solid Carbide End Mill for Dynamic Milling

Material Number7073712

ISO Catalog ID772TM12016RXWANSI Catalog ID772TM12016RXW

Trochoidal Milling

Flute Configuration: 7

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Square End

Helix Angle: 38°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7073712 |

| ISO Catalog ID | 772TM12016RXW |

| ANSI Catalog ID | 772TM12016RXW |

| Grade | WS15PE |

| Adapter Style Machine Side | Weldon |

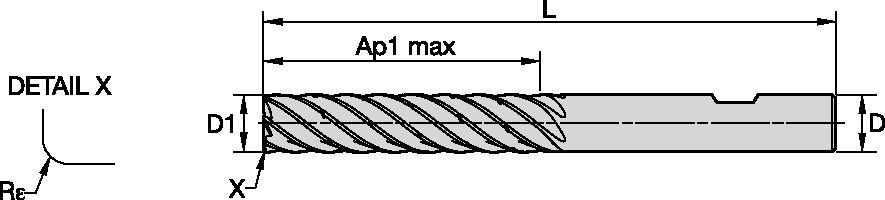

| [D1] Effective Cutting Diameter | 12 mm |

| [D1] Effective Cutting Diameter | 0.4724 in |

| [D] Adapter / Shank / Bore Diameter | 12 mm |

| [D] Adapter / Shank / Bore Diameter | 0.4724 in |

| [AP1MAX] 1st Maximum Cutting Depth | 62 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 2.4409 in |

| [L] Overall Length | 125 mm |

| [L] Overall Length | 4.9213 in |

| [Re] Corner Radius | 0.3 mm |

| [Re] Corner Radius | 0.012 in |

| [Z] Number of Flutes | 7 |

Uses and application

Trochoidal Milling

Flute Configuration: 7

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Square End

Helix Angle: 38°

Grades

WS15PE

PVD-coated carbide grade with optimized chemistry and process for increased wear resistance. State-of-the-art, post-coat treatment reduces friction and helps manage heat when cutting super alloys.

Features and benefits

- With chip splitters for perfect chip evacuation and high surface quality.

- 7-fluted solid carbide end mill for steel, stainless steel and high temperature alloys.

- 5xD length of cut for maximum metal removal rates.

- Unequal flute spacing reduces vibrations and improves tool life.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Recommended feed per tooth (fz=mm/th) for side milling at ae = 5% of D1 | |||||||||||

| WS15PE | D1 | ||||||||||

| Side Milling | Cutting Speed | ||||||||||

| Material | ap | ae | Min | Start | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | |

| P | 0 | Ap max | 0,05 x D1 | 300 | 350 | 400 | fz | 0,115 | 0,132 | 0,161 | 0,182 |

| 1 | Ap max | 0,05 x D1 | 300 | 350 | 400 | fz | 0,115 | 0,132 | 0,161 | 0,182 | |

| 2 | Ap max | 0,05 x D1 | 280 | 330 | 380 | fz | 0,115 | 0,132 | 0,161 | 0,182 | |

| 3 | Ap max | 0,05 x D1 | 240 | 280 | 320 | fz | 0,097 | 0,112 | 0,140 | 0,162 | |

| 4 | Ap max | 0,05 x D1 | 180 | 240 | 300 | fz | 0,086 | 0,100 | 0,123 | 0,141 | |

| 5 | Ap max | 0,05 x D1 | 120 | 160 | 200 | fz | 0,077 | 0,090 | 0,112 | 0,129 | |

| 6 | Ap max | 0,05 x D1 | 100 | 125 | 150 | fz | 0,065 | 0,074 | 0,091 | 0,104 | |

| M | 1 | Ap max | 0,05 x D1 | 180 | 205 | 230 | fz | 0,097 | 0,112 | 0,140 | 0,162 |

| 2 | Ap max | 0,05 x D1 | 120 | 140 | 160 | fz | 0,077 | 0,090 | 0,112 | 0,129 | |

| 3 | Ap max | 0,05 x D1 | 120 | 130 | 140 | fz | 0,065 | 0,074 | 0,091 | 0,104 | |

| K | 1 | Ap max | 0,05 x D1 | 240 | 270 | 300 | fz | 0,115 | 0,132 | 0,161 | 0,182 |

| 2 | Ap max | 0,05 x D1 | 220 | 250 | 280 | fz | 0,097 | 0,112 | 0,140 | 0,162 | |

| 3 | Ap max | 0,05 x D1 | 220 | 240 | 260 | fz | 0,077 | 0,090 | 0,112 | 0,129 | |

| S | 1 | Ap max | 0,05 x D1 | 100 | 140 | 180 | fz | 0,097 | 0,112 | 0,140 | 0,162 |

| 2 | Ap max | 0,05 x D1 | 50 | 65 | 80 | fz | 0,077 | 0,090 | 0,112 | 0,129 | |

| 3 | Ap max | 0,05 x D1 | 50 | 65 | 80 | fz | 0,051 | 0,060 | 0,074 | 0,086 | |

| 4 | Ap max | 0,05 x D1 | 100 | 110 | 120 | fz | 0,071 | 0,083 | 0,103 | 0,119 | |

| H | 1 | Ap max | 0,05 x D1 | 160 | 220 | 280 | fz | 0,086 | 0,100 | 0,123 | 0,141 |

| 2 | Ap max | 0,05 x D1 | 140 | 190 | 240 | fz | 0,065 | 0,074 | 0,091 | 0,104 | |

| Recommended feed per tooth (fz=mm/th) for side milling at ae = 10% of D1 | |||||||||||

| WS15PE | D1 | ||||||||||

| Side Milling | Cutting Speed | ||||||||||

| Material | ap | ae | Min | Start | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | |

| P | 0 | Ap max | 0,1 x D1 | 270 | 315 | 360 | fz | 0,094 | 0,108 | 0,131 | 0,148 |

| 1 | Ap max | 0,1 x D1 | 270 | 315 | 360 | fz | 0,094 | 0,108 | 0,131 | 0,148 | |

| 2 | Ap max | 0,1 x D1 | 252 | 297 | 342 | fz | 0,094 | 0,108 | 0,131 | 0,148 | |

| 3 | Ap max | 0,1 x D1 | 216 | 252 | 288 | fz | 0,079 | 0,091 | 0,113 | 0,131 | |

| 4 | Ap max | 0,1 x D1 | 162 | 216 | 270 | fz | 0,070 | 0,081 | 0,100 | 0,114 | |

| 5 | Ap max | 0,1 x D1 | 108 | 144 | 180 | fz | 0,063 | 0,073 | 0,091 | 0,105 | |

| 6 | Ap max | 0,1 x D1 | 90 | 113 | 135 | fz | 0,053 | 0,061 | 0,074 | 0,084 | |

| M | 1 | Ap max | 0,1 x D1 | 162 | 185 | 207 | fz | 0,079 | 0,091 | 0,113 | 0,131 |

| 2 | Ap max | 0,1 x D1 | 108 | 126 | 144 | fz | 0,063 | 0,073 | 0,091 | 0,105 | |

| 3 | Ap max | 0,1 x D1 | 108 | 117 | 126 | fz | 0,053 | 0,061 | 0,074 | 0,084 | |

| K | 1 | Ap max | 0,1 x D1 | 216 | 243 | 270 | fz | 0,094 | 0,108 | 0,131 | 0,148 |

| 2 | Ap max | 0,1 x D1 | 198 | 225 | 252 | fz | 0,079 | 0,091 | 0,113 | 0,131 | |

| 3 | Ap max | 0,1 x D1 | 198 | 216 | 234 | fz | 0,063 | 0,073 | 0,091 | 0,105 | |

| S | 1 | Ap max | 0,1 x D1 | 90 | 126 | 162 | fz | 0,079 | 0,091 | 0,113 | 0,131 |

| 2 | Ap max | 0,1 x D1 | 45 | 59 | 72 | fz | 0,063 | 0,073 | 0,091 | 0,105 | |

| 3 | Ap max | 0,1 x D1 | 45 | 59 | 72 | fz | 0,042 | 0,048 | 0,060 | 0,070 | |

| 4 | Ap max | 0,1 x D1 | 90 | 99 | 108 | fz | 0,058 | 0,067 | 0,083 | 0,097 | |

| H | 1 | Ap max | 0,1 x D1 | 144 | 198 | 252 | fz | 0,070 | 0,081 | 0,100 | 0,114 |

| 2 | Ap max | 0,1 x D1 | 126 | 171 | 216 | fz | 0,053 | 0,061 | 0,074 | 0,084 | |

| Recommended feed per tooth (fz=mm/th) for side milling at ae = 2% of D1 | |||||||||||

| WS15PE | D1 | ||||||||||

| Side Milling | Cutting Speed | ||||||||||

| Material | ap | ae | Min | Start | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | |

| P | 0 | Ap max | 0,02 x D1 | 308 | 359 | 410 | fz | 0,173 | 0,199 | 0,242 | 0,274 |

| 1 | Ap max | 0,02 x D1 | 308 | 359 | 410 | fz | 0,173 | 0,199 | 0,242 | 0,274 | |

| 2 | Ap max | 0,02 x D1 | 287 | 338 | 390 | fz | 0,173 | 0,199 | 0,242 | 0,274 | |

| 3 | Ap max | 0,02 x D1 | 246 | 287 | 328 | fz | 0,145 | 0,168 | 0,209 | 0,242 | |

| 4 | Ap max | 0,02 x D1 | 185 | 246 | 308 | fz | 0,130 | 0,150 | 0,184 | 0,211 | |

| 5 | Ap max | 0,02 x D1 | 123 | 164 | 205 | fz | 0,116 | 0,135 | 0,167 | 0,194 | |

| 6 | Ap max | 0,02 x D1 | 103 | 128 | 154 | fz | 0,097 | 0,112 | 0,137 | 0,156 | |

| M | 1 | Ap max | 0,02 x D1 | 185 | 210 | 236 | fz | 0,145 | 0,168 | 0,209 | 0,242 |

| 2 | Ap max | 0,02 x D1 | 123 | 144 | 164 | fz | 0,116 | 0,135 | 0,167 | 0,194 | |

| 3 | Ap max | 0,02 x D1 | 123 | 133 | 144 | fz | 0,097 | 0,112 | 0,137 | 0,156 | |

| K | 1 | Ap max | 0,02 x D1 | 246 | 277 | 308 | fz | 0,173 | 0,199 | 0,242 | 0,274 |

| 2 | Ap max | 0,02 x D1 | 226 | 256 | 287 | fz | 0,145 | 0,168 | 0,209 | 0,242 | |

| 3 | Ap max | 0,02 x D1 | 226 | 246 | 267 | fz | 0,116 | 0,135 | 0,167 | 0,194 | |

| S | 1 | Ap max | 0,02 x D1 | 103 | 144 | 185 | fz | 0,145 | 0,168 | 0,209 | 0,242 |

| 2 | Ap max | 0,02 x D1 | 51 | 67 | 82 | fz | 0,116 | 0,135 | 0,167 | 0,194 | |

| 3 | Ap max | 0,02 x D1 | 51 | 67 | 82 | fz | 0,077 | 0,089 | 0,111 | 0,130 | |

| 4 | Ap max | 0,02 x D1 | 103 | 113 | 123 | fz | 0,107 | 0,124 | 0,154 | 0,178 | |

| H | 1 | Ap max | 0,02 x D1 | 164 | 226 | 287 | fz | 0,130 | 0,150 | 0,184 | 0,211 |

| 2 | Ap max | 0,02 x D1 | 144 | 195 | 246 | fz | 0,097 | 0,112 | 0,137 | 0,156 | |

I have read and accepted the Terms & Conditions of use