Erreichen Sie die nächste Stufe beim Hochvorschubfräsen

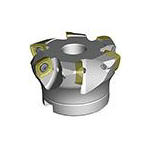

Die neue VXF™-Baureihe kombiniert die besten Eigenschaften runder und quadratischer Wendeschneidplatten, um die Zeitspanungsvolumina zu steigern und die nächste Stufe des Fräsens mit hohem Vorschub zu erreichen, was sie zur ersten Wahl für die Bearbeitung mit langer Auskragung macht.

Der Winkel von 16,5° und die spezielle Wendeschneidplattengeometrie reduzieren Abdrängung und Vibrationen, während die axialen und radialen Breitschlichtfasen zu einer verbesserten Oberflächenqualität and Wandung und Bearbeitungsgrund führen.

Von den zwei verfügbaren Wendeschneidplattengeometrien eignet sich die MM Geometrie am besten zum Auskammern und Vorfräsen von Konturen bei Stählen, rostfreien Edelstählen und Hochtemperaturlegierungen. Die MH Geometrie bietet einen stärkeren Schutz der Schneidkante für schwere Schrupparbeiten für hochvergütete Stahlwerkstoffe.

VXF-Hochvorschubfräser können auf anspruchsvollen Werkstückformen mit bis zu 9 verschiedenen Bearbeitungsoperationen auf unterschiedlichsten Werkstoffen eingesetzt werden und sind damit eine universelle Lösung für verschiedene Anforderungen.