Produkt ähnlich wie:

45C7 45C8 • Multi-Flute Finisher • Inch

45C8 • Multi-Flute Finisher • 45° Helix • Inch

Material Nummer6127036

ISO Katalog Nummer45C825FDL25ANSI Katalog Nummer45C825FDL25

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Schneideckenausführung: Eckenradius

Spiralwinkel: 45°

Werkzeugabmessungen: Schneidreihen: 6

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

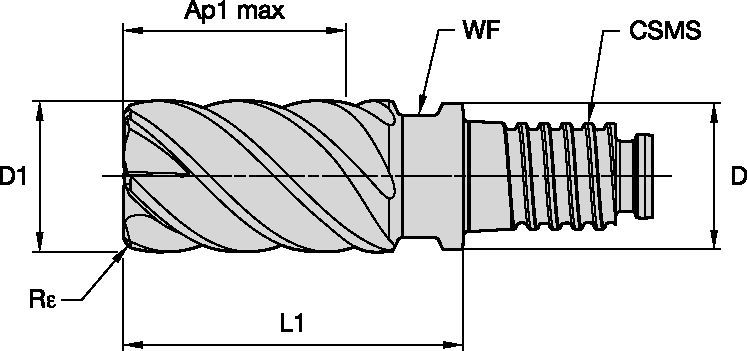

| Material Nummer | 6127036 |

| ISO Katalog Nummer | 45C825FDL25 |

| ANSI Katalog Nummer | 45C825FDL25 |

| Sorte | WS15PE |

| Aufnahmeart Maschinenseite | DUO-LOCK |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 24.4 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.9606 in |

| [L1] Messlänge | 57.2 mm |

| [L1] Messlänge | 2.252 in |

| [CSMS] Systemgröße – Maschinenseite | DL25 |

| [WF] Flächenbreite | 21 mm |

| [WF] Flächenbreite | 0.8268 in |

| [Re] Eckenradius | 6.35 mm |

| [Re] Eckenradius | 0.25 in |

| [Z] Anzahl der Spannuten | 10 |

| [D1] Effektiver Schneidendurchmesser | 25.4 mm |

| [D1] Effektiver Schneidendurchmesser | 1 in |

| [AP1MAX] 1. maximale Schnitttiefe | 38.1 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 1.5 in |

Uses and application

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Schneideckenausführung: Eckenradius

Spiralwinkel: 45°

Werkzeugabmessungen: Schneidreihen: 6

Grades

WS15PE

PVD-beschichtete Hartmetallsorte mit optimierter Zusammensetzung und ein optimierter Prozess bieten höhere Verschleißfestigkeit. Dem neuesten Stand der Technik entsprechende Beschichtungs-Nachbehandlung sorgt für reduzierte Reibung und ein verbessertes Wärmemanagement bei der spanhebenden Bearbeitung von Superlegierungen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

45C7 • Multi-Flute Finisher • Inch

|  | ||||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Auskraglänge der | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | |||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Werkstoffgruppe | ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 1 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 2 | 1.5 x D | 0.05 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 3 | 1.5 x D | 0.05 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 4 | 1.5 x D | 0.05 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 | |

| 5 | 1.5 x D | 0.05 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 6 | 1.5 x D | 0.05 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| M | 1 | 1.5 x D | 0.05 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 3 | 1.5 x D | 0.05 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| K | 1 | 1.5 x D | 0.05 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 2 | 1.5 x D | 0.05 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 3 | 1.5 x D | 0.05 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| S | 1 | 1.5 x D | 0.05 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 3 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 4 | 1.5 x D | 0.05 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0017 | .0021 | .0025 | .0028 | .0033 | .0036 | |

| H | 1 | 1.5 x D | 0.04 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 |

| 2 | 1.5 x D | 0.04 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

45C8 • Multi-Flute Finisher • Inch

|  | ||||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Auskraglänge der | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | |||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Werkstoffgruppe | ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 1 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 2 | 1.5 x D | 0.05 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 3 | 1.5 x D | 0.05 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 4 | 1.5 x D | 0.05 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 | |

| 5 | 1.5 x D | 0.05 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 6 | 1.5 x D | 0.05 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| M | 1 | 1.5 x D | 0.05 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 3 | 1.5 x D | 0.05 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| K | 1 | 1.5 x D | 0.05 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 2 | 1.5 x D | 0.05 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 3 | 1.5 x D | 0.05 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| S | 1 | 1.5 x D | 0.05 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 3 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 4 | 1.5 x D | 0.05 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0017 | .0021 | .0025 | .0028 | .0033 | .0036 | |

| H | 1 | 1.5 x D | 0.04 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 |

| 2 | 1.5 x D | 0.04 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data