Produkt ähnlich wie:

45C7 45C8 • Multi-Flute Finisher • Inch

45C8 • Multi-Flute Finisher • 45° Helix • Inch

Material Nummer6127553

ISO Katalog Nummer45C710ADL10ANSI Katalog Nummer45C710ADL10

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Schneideckenausführung: Eckenradius

Spiralwinkel: 45°

Werkzeugabmessungen: Schneidreihen: 6

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

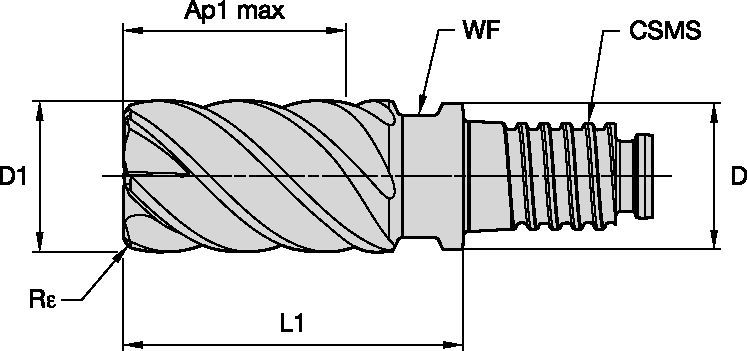

| Material Nummer | 6127553 |

| ISO Katalog Nummer | 45C710ADL10 |

| ANSI Katalog Nummer | 45C710ADL10 |

| Sorte | WP15PE |

| Aufnahmeart Maschinenseite | DUO-LOCK |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 9.525 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.375 in |

| [L1] Messlänge | 21.4 mm |

| [L1] Messlänge | 0.8425 in |

| [CSMS] Systemgröße – Maschinenseite | DL10 |

| [WF] Flächenbreite | 8 mm |

| [WF] Flächenbreite | 0.315 in |

| [Re] Eckenradius | 0.375 mm |

| [Re] Eckenradius | 0.015 in |

| [Z] Anzahl der Spannuten | 6 |

| [D1] Effektiver Schneidendurchmesser | 9.525 mm |

| [D1] Effektiver Schneidendurchmesser | 0.375 in |

| [AP1MAX] 1. maximale Schnitttiefe | 14.288 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.5625 in |

Uses and application

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Schneideckenausführung: Eckenradius

Spiralwinkel: 45°

Werkzeugabmessungen: Schneidreihen: 6

Grades

WP15PE

Hartmetallschneidstoff mit einer dicken, prozessoptimierten PVD-Beschichtung mit einer höheren Verschleißfestigkeit Überragender Schutz vor Kolk-, Kerb- und Freiflächenverschleiß bei der Bearbeitung von nicht rostendem Stahl. Ausgezeichnete Leistung bei Härten von bis zu 52 HRC.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

45C7 • Multi-Flute Finisher • Inch

|  | ||||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Auskraglänge der | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | |||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Werkstoffgruppe | ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 1 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 2 | 1.5 x D | 0.05 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 3 | 1.5 x D | 0.05 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 4 | 1.5 x D | 0.05 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 | |

| 5 | 1.5 x D | 0.05 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 6 | 1.5 x D | 0.05 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| M | 1 | 1.5 x D | 0.05 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 3 | 1.5 x D | 0.05 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| K | 1 | 1.5 x D | 0.05 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 2 | 1.5 x D | 0.05 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 3 | 1.5 x D | 0.05 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| S | 1 | 1.5 x D | 0.05 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 3 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 4 | 1.5 x D | 0.05 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0017 | .0021 | .0025 | .0028 | .0033 | .0036 | |

| H | 1 | 1.5 x D | 0.04 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 |

| 2 | 1.5 x D | 0.04 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

45C8 • Multi-Flute Finisher • Inch

|  | ||||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Auskraglänge der | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | |||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Werkstoffgruppe | ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 1 | 1.5 x D | 0.05 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 2 | 1.5 x D | 0.05 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 | |

| 3 | 1.5 x D | 0.05 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 4 | 1.5 x D | 0.05 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 | |

| 5 | 1.5 x D | 0.05 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 6 | 1.5 x D | 0.05 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| M | 1 | 1.5 x D | 0.05 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| 3 | 1.5 x D | 0.05 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

| K | 1 | 1.5 x D | 0.05 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0027 | .0034 | .0039 | .0044 | .0049 | .0049 |

| 2 | 1.5 x D | 0.05 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 | |

| 3 | 1.5 x D | 0.05 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 | |

| S | 1 | 1.5 x D | 0.05 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0023 | .0029 | .0034 | .0039 | .0045 | .0048 |

| 2 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 3 | 1.5 x D | 0.05 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0012 | .0015 | .0018 | .0021 | .0024 | .0026 | |

| 4 | 1.5 x D | 0.05 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0017 | .0021 | .0025 | .0028 | .0033 | .0036 | |

| H | 1 | 1.5 x D | 0.04 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0020 | .0026 | .0030 | .0034 | .0039 | .0040 |

| 2 | 1.5 x D | 0.04 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0015 | .0019 | .0022 | .0025 | .0028 | .0029 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data