Hoş Geldiniz

Lütfen tercihlerinizi onaylayın

Tercihleri Güncelle

Ürün Önerileri

Product Family suggestions

Merhaba, User Name

Seçtiğiniz Hesap:

There is an issue with your account. Please contact customer support.

Sold To Account Hesabı Değiştir

Ship To Account Hesabı Değiştir

- Kontrol Paneli

- Siparişleri Yönet

- Kanalları Yönet

- Adres Defteri

Bildirimler

Tümünü okundu olarak işaretle- Parolayı Değiştir

- Profilim

- Oturumu Kapat

Ürün(ler) sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Güçlü takımlama çözümleri indirimde. Şimdi satın alın.

Ürün(ler) sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Ürünler

- /

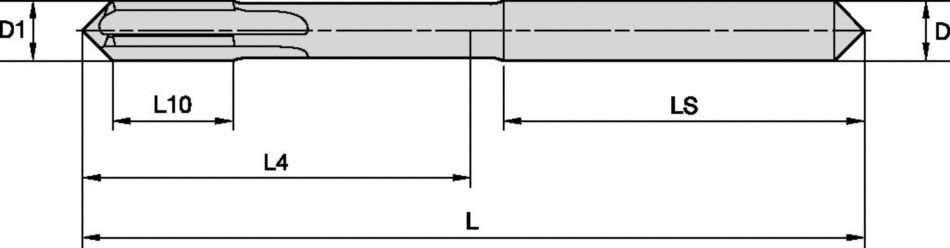

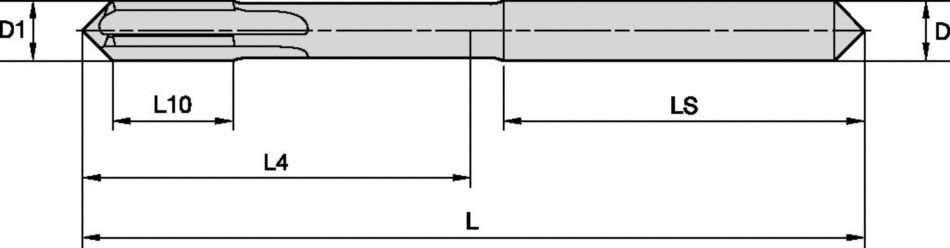

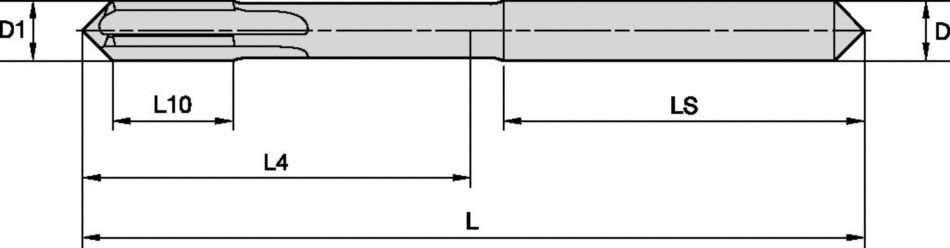

- Raybalar, kör delikler için • 1,4–4,15mm (0,055–0,163 inç) • K10F • K10F-DCFD • "HA" Şaft

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

Raybalar, kör delikler için • 1,4–4,15mm (0,055–0,163 inç) • K10F • K10F-DCFD • "HA" Şaft

HSR™ Karbür raybalama takımları

Özellikler ve avantajlar

- Listelenen standart raybalar, H7 tolerans deliği elde etmek için taşlanmıştır. Siparişe göre ek çaplar ve boylar.

Kullanım ve uygulama alanları

Reaming: Blind Hole

Reaming: Blind & Cross

Flood Coolant: Reaming