Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

WIDIA steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Leistungsstarke Werkzeuglösungen jetzt im Angebot.

Bestellen Sie jetzt!

WIDIA steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

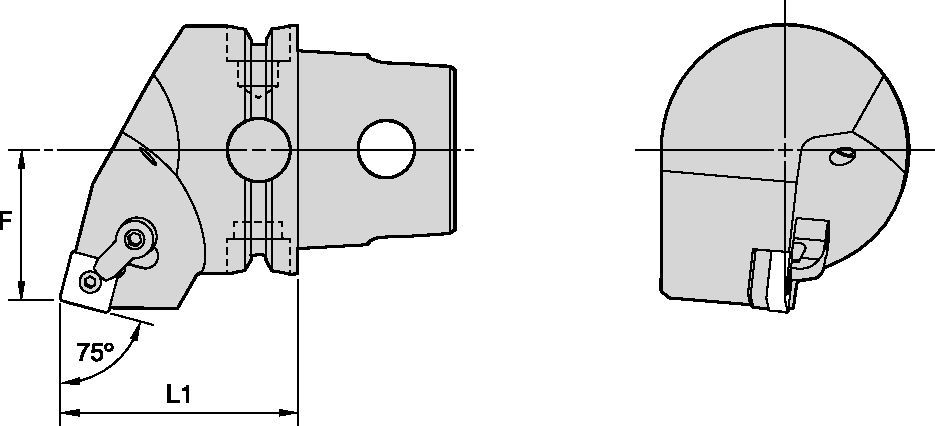

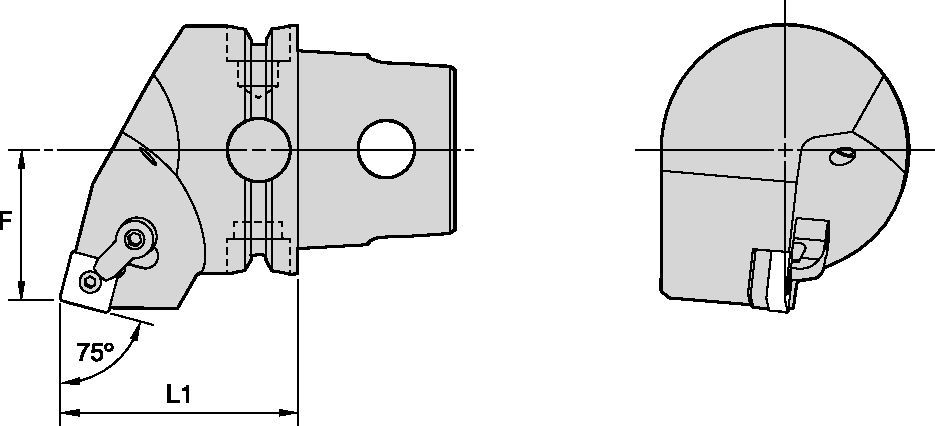

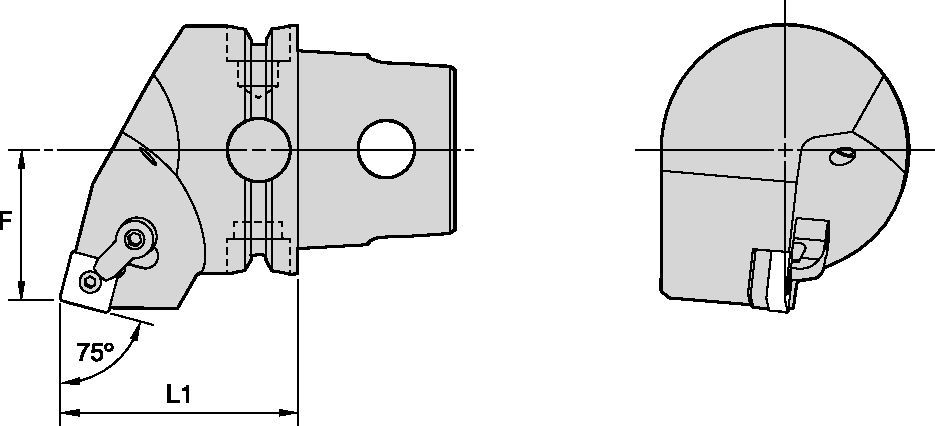

- MSRN 75°

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

MSRN 75°

M-Clamping

Uses and application

Shank - KM-TS ISO 26622

Schaft – KM-TS ISO 26622

Coolant — Through Coolant 100 bar (1500 psi) Maximum

Kühlmittel – Innere Kühlmittelzuführung 100 bar (1500 psi) Maximum