Product Similar To :

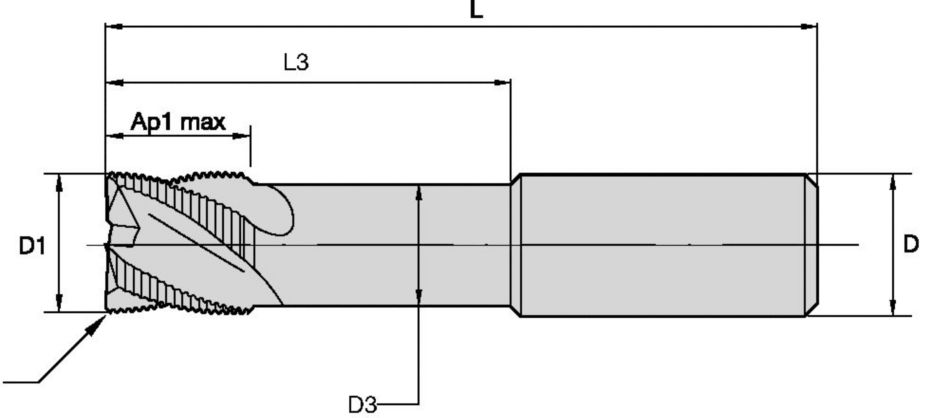

HSS Roughers • Series 6NL6 • Chamfer • Neck • Weldon® • Metric

Series 6NL6

Material Number1660629

ISO Catalog ID6NL616006LWANSI Catalog ID6NL616006LW

Ramping: Blank

Slotting: Square End

Corner Style: Corner Chamfer

Side Milling/Shoulder Milling: Square End

38491

Helix Angle: 30°

Tool Dimensions: Flute Configuration: X (variable)

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1660629 |

| ISO Catalog ID | 6NL616006LW |

| ANSI Catalog ID | 6NL616006LW |

| Coating | TiAlN |

| Adapter Style Machine Side | Weldon |

| [D1] Effective Cutting Diameter | 16 mm |

| [D1] Effective Cutting Diameter | 0.63 in |

| [D] Adapter / Shank / Bore Diameter | 16 mm |

| [D] Adapter / Shank / Bore Diameter | 0.6299 in |

| [AP1MAX] 1st Maximum Cutting Depth | 32 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.26 in |

| [L3] Usable Length | 87 mm |

| [L3] Usable Length | 3.425 in |

| [L] Overall Length | 138 mm |

| [L] Overall Length | 5.433 in |

| [BCH] Corner Chamfer Width | 0.35 mm |

| [BCH] Corner Chamfer Width | 0.014 in |

| [D3] Neck Diameter | 15 mm |

| [D3] Neck Diameter | 0.5906 in |

| [Z] Number of Flutes | 4 |

Uses and application

Ramping: Blank

Slotting: Square End

Corner Style: Corner Chamfer

Side Milling/Shoulder Milling: Square End

38491

Helix Angle: 30°

Tool Dimensions: Flute Configuration: X (variable)

Features and benefits

- Center cutting.

- Fine pitch.

- Standard items listed. Additional styles and coatings made-to-order.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Series 6NL6

|  |  | |||||||||||

| Side Milling (A) and Slotting (B) | TiAlN | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||

| A | B | Cutting Speed | D1 | ||||||||||

| Material | ap | ae | ap | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 1 | 1,5 x D | 0,5 x D | 1 x D | 70 | – | 80 | fz | 0,063 | 0,070 | 0,085 | 0,096 | 0,104 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 80 | fz | 0,063 | 0,070 | 0,085 | 0,096 | 0,104 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 50 | – | 70 | fz | 0,053 | 0,059 | 0,073 | 0,085 | 0,096 | |

| 5 | 1,5 x D | 0,5 x D | 1 x D | 25 | – | 35 | fz | 0,042 | 0,047 | 0,059 | 0,068 | 0,076 | |

| M | 1 | 1,5 x D | 0,5 x D | 1 x D | 25 | – | 35 | fz | 0,053 | 0,059 | 0,073 | 0,085 | 0,096 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 25 | – | 30 | fz | 0,042 | 0,047 | 0,059 | 0,068 | 0,076 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 15 | – | 20 | fz | 0,035 | 0,039 | 0,048 | 0,054 | 0,060 | |

| K | 1 | 1,5 x D | 0,5 x D | 1 x D | 70 | – | 80 | fz | 0,063 | 0,070 | 0,085 | 0,096 | 0,104 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 50 | – | 70 | fz | 0,053 | 0,059 | 0,073 | 0,085 | 0,096 | |

| S | 1 | 1,5 x D | 0,5 x D | 1 x D | 15 | – | 30 | fz | 0,053 | 0,059 | 0,073 | 0,085 | 0,096 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 5 | – | 15 | fz | 0,028 | 0,031 | 0,039 | 0,045 | 0,051 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 15 | – | 30 | fz | 0,042 | 0,047 | 0,059 | 0,068 | 0,076 | |

| 4 | 1,5 x D | 0,5 x D | 1 x D | 10 | – | 20 | fz | 0,039 | 0,043 | 0,054 | 0,062 | 0,070 | |

I have read and accepted the Terms & Conditions of use