Product Similar To:

TT HPV-CV Form B/AD

Shrink Fit Toolholders General Purpose (GP)

Material Number3615200

ISO Catalog IDCV50HPVTT100800ANSI Catalog IDCV50HPVTT100800

Axial Adjustment - End

Shank - 1"–8 unc Drawbar

Accuracy - 3μm or Less

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Shank - SK CAT(CV) ANSI B5.50

Balance - G 6.3@15,000 min -1

Shank - SK CAT(CV) ANSI B5.50 1"–8 unc Drawbar

Balance - G 6.3@15,000 min-1

Shank - SK CAT(CV) ANSI B5.50 5/8"–11 unc Drawbar

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3615200 |

| ISO Catalog ID | CV50HPVTT100800 |

| ANSI Catalog ID | CV50HPVTT100800 |

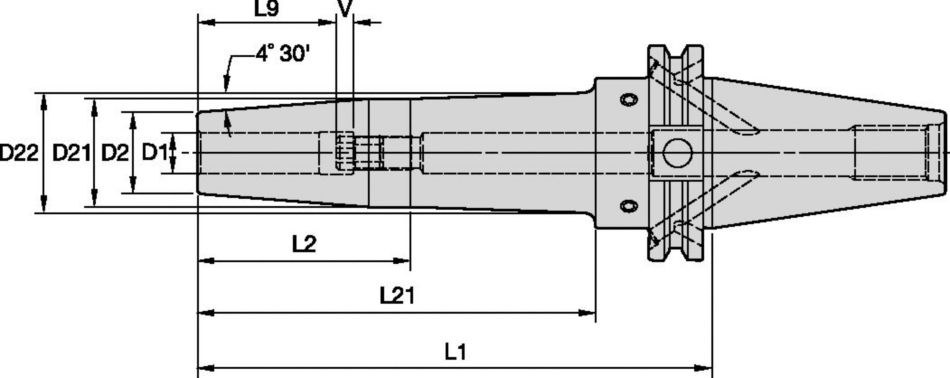

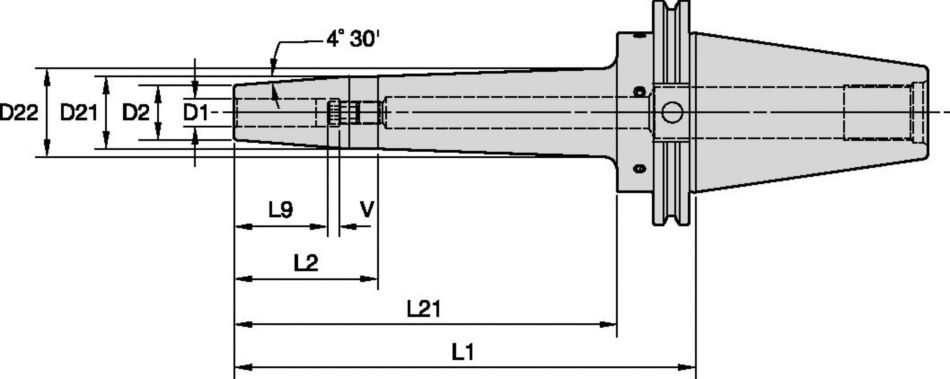

| [D1] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D1] Adapter / Shank / Bore Diameter | 1 in |

| [D2] Body Diameter 1 Workpiece Side | 44 mm |

| [D2] Body Diameter 1 Workpiece Side | 1.732 in |

| [D21] Body Diameter 2 Workpiece Side | 52.9 mm |

| [D21] Body Diameter 2 Workpiece Side | 2.083 in |

| Max Diameter Taper Angle [D22] | 59.76 mm |

| Max Diameter Taper Angle [D22] | 2.353 in |

| [L1] Gage Length | 203.2 mm |

| [L1] Gage Length | 8 in |

| [L2] Usable Length | 70.104 mm |

| [L2] Usable Length | 2.76 in |

| [L21] Usable Length | 168.275 mm |

| [L21] Usable Length | 6.625 in |

| [L9] Clamping Length | 47 mm |

| [L9] Clamping Hole Length | 1.85 in |

| [V] Adjustment Range | 10 mm |

| [V] Adjustment Range | 0.3937 in |

| Stop Screw ID Drive Size | 8 mm |

| Weight Kilograms | 5.45 |

Uses and application

Axial Adjustment - End

Shank - 1"–8 unc Drawbar

Accuracy - 3μm or Less

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Shank - SK CAT(CV) ANSI B5.50

Balance - G 6.3@15,000 min -1

Shank - SK CAT(CV) ANSI B5.50 1"–8 unc Drawbar

Balance - G 6.3@15,000 min-1

Shank - SK CAT(CV) ANSI B5.50 5/8"–11 unc Drawbar

Features and benefits

- Balanceable — fine tune with optional M6 set screws.

- Suitable for carbide and HSS cutting tools (requirements below).

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use