U.S customers, a 5% tariff surcharge will be added to your order for metal cutting products.

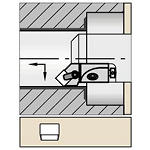

C-Style Clamping • For Ceramic Inserts

Filters

Filters

View filters in

MetricInch

Applications

Applications

CRT Profiling (2)

ID Facing (2)

Multiple Direction Cutting (2)

Over All Length [L]

Over All Length [L]

- 1.9717 in(1)

- 2.178 in(1)

to

Over All Length [L]

Over All Length [L]

- 50.08 mm(1)

- 55.32 mm(1)

to

Application

Minimum Axial Groove Diameter

Minimum Axial Groove Diameter

- 40.0 mm(1)

- 50.0 mm(1)

to

Minimum Axial Groove Diameter

Minimum Axial Groove Diameter

- 1.5748 in(1)

- 1.9685 in(1)

to

Front-End

Cartridge Size

Cartridge Size

- 10 - mm of Cutting Height (1)

- 12 - mm of Cutting Height (1)

No filters matching ""