How to Choose the Best Solid Carbide End Mill Design for your Application

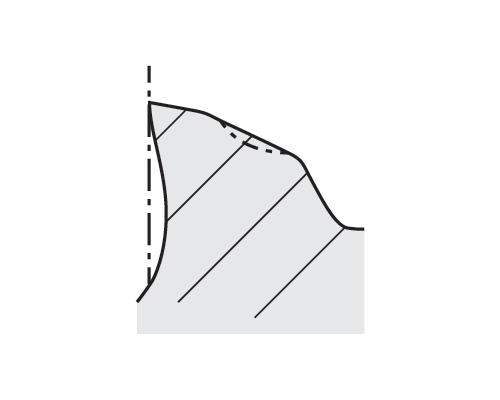

Did you know that there are two major endmill designs available on the market today? The first is the “Conventional” design, which is most common. It features primary “relief” with a secondary clearance that is flat or concave. The clearance angle is measured over the high points at the angle transitions. It is easy to regrind and can be used for both axial and radial clearances.

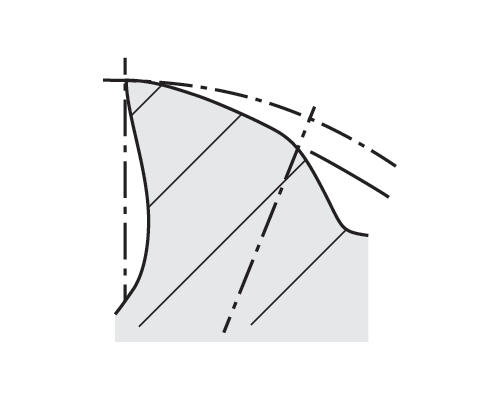

The other design is “Eccentric.” Eccentric relief endmill design on the other hand, combines the primary and secondary relief into one constant drop. The continuous drop provides the strongest cutting edge. However, the eccentric grind is primarily used for radial clearance. So, on many endmills with the ER grind, you will still see the Primary/Secondary on the face.

Now that we understand the technical differences between the two styles of endmill designs, the next question is which design is likely to work well for your next application. The chart below shows when each type of design is likely to work best with your application:

Primary Secondary 5V0C Thinner sharper cutting edges for best shearing action. Can take light depths of cuts and produce very fine finishes. Because it’s sharp it can be prone to chatter. More prone to chipping if recuts chips.

Primary Secondary 5V0C Thinner sharper cutting edges for best shearing action. Can take light depths of cuts and produce very fine finishes. Because it’s sharp it can be prone to chatter. More prone to chipping if recuts chips. Eccentric 5V0C Strong cutting edges. Likes higher feed rates. Needs to take a bite of material to work properly. Easily pushes the heat into the chip. Performs very well in harder materials.

Eccentric 5V0C Strong cutting edges. Likes higher feed rates. Needs to take a bite of material to work properly. Easily pushes the heat into the chip. Performs very well in harder materials.

The eccentric relief works very well in most materials, but there is still a valuable reason to use the primary/secondary grind. The primary/secondary grind is capable of machining softer materials, light depths of cut, thin walled parts, etc. For this reason, you’ll always see a combination of the two styles offered, to cover most situations.