Product Similar To :

Shrink Fit HSK63A • MQL 1 Channel • Metric

Shrink Fit Toolholder thermo tool and MQL channel

Material Number7144740

ISO Catalog IDHSK63ATTA2MQL1C10085MANSI Catalog IDHSK63ATTA2MQL1C10085M

100129300

Axial Adjustment - End

Accuracy - 3μm or Less

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Shank - HSK DIN 69893

Shank - HSK DIN 69893 Form A

Balance (G 2.5/25,000)

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 7144740 |

| ISO Catalog ID | HSK63ATTA2MQL1C10085M |

| ANSI Catalog ID | HSK63ATTA2MQL1C10085M |

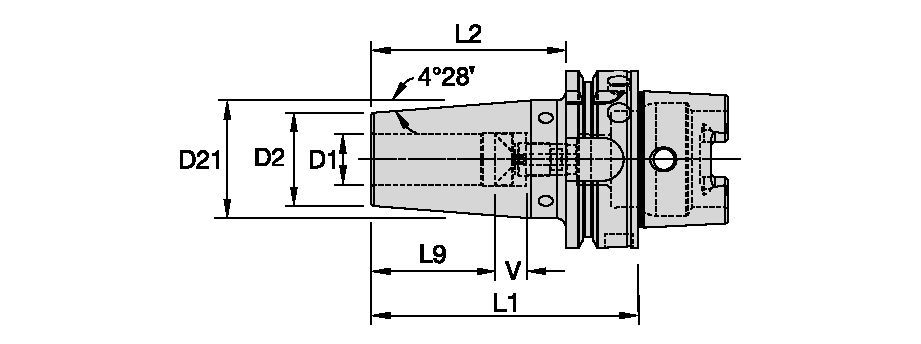

| [D1] Adapter / Shank / Bore Diameter | 10 mm |

| [D1] Adapter / Shank / Bore Diameter | 0.3937 in |

| [D2] Body Diameter 1 Workpiece Side | 24 mm |

| [D2] Body Diameter 1 Workpiece Side | 0.9449 in |

| [D21] Body Diameter 2 Workpiece Side | 31.9 mm |

| [D21] Body Diameter 2 Workpiece Side | 1.2559 in |

| [L1] Gage Length | 85 mm |

| [L1] Gage Length | 3.3465 in |

| [L2] Usable Length | 59.05 mm |

| [L2] Usable Length | 2.3248 in |

| [L9] Clamping Length | 31 mm |

| [L9] Clamping Hole Length | 1.2205 in |

| [V] Adjustment Range | 10 mm |

| [V] Adjustment Range | 0.3937 in |

| Weight Kilograms | 0.92 |

Uses and application

100129300

Axial Adjustment - End

Accuracy - 3μm or Less

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Shank - HSK DIN 69893

Shank - HSK DIN 69893 Form A

Balance (G 2.5/25,000)

Features and benefits

- MQL1 single channel systems for general machining.

- Shrink Fit chucks provide high gripping force and is safe 5 axis machining.

- HSK63A connections with secure interface for most MQL backends .

- Short and extended gauge lengths for ridged machining of a wide range of components.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use