Product Similar To :

TDS401A • A-Shank • WP20PD™ • 3 x D

TDS401A • 3 x D

Material Number4163289

ISO Catalog IDTDS401A18654ANSI Catalog IDTDS401A18654

Drilling

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

38513

38550

38563

Drilling Depth: 3x

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4163289 |

| ISO Catalog ID | TDS401A18654 |

| ANSI Catalog ID | TDS401A18654 |

| Grade | WP20PD |

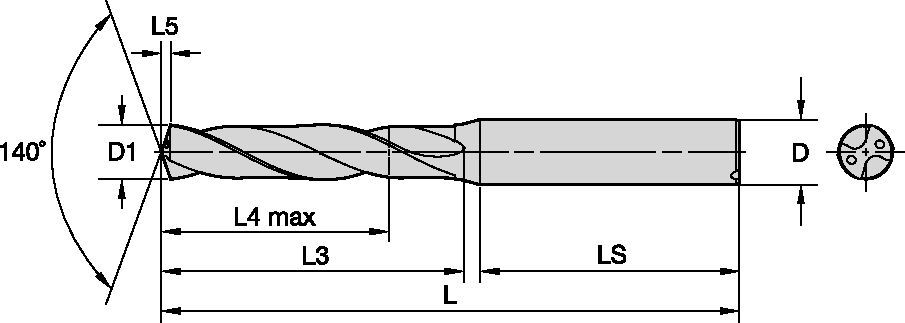

| [D1] Drill Diameter M | 18.654 mm |

| [D1] Drill Diameter M | 0.7344 in |

| [L] Overall Length | 131 mm |

| [L] Overall Length | 5.1575 in |

| [L3] Flute Length | 79 mm |

| [L3] Flute Length | 3.1102 in |

| [L4] Maximum Drilling Depth | 55 mm |

| [L4] Maximum Drilling Depth | 2.1654 in |

| [L5] Drill Point Length | 3.24 mm |

| [L5] Drill Point Length | 0.1276 in |

| [LS] Shank Length | 50 mm |

| [LS] Shank Length | 1.9685 in |

| [D] Adapter / Shank / Bore Diameter | 20 mm |

| [D] Adapter / Shank / Bore Diameter | 0.7874 in |

Uses and application

Drilling

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

38513

38550

38563

Drilling Depth: 3x

Grades

WP20PD

Composition: With a multilayered PVD TiN-TiAlN coating, a high-quality submicron carbide substrate and a state-of-the-art surface condition, this grade gives the highest level of wear resistance at high cutting speeds.

Application: A high productivity grade for high speeds and feeds. First choice for high productivity with excellent reliability in alloyed and high-alloyed steels and cast irons.

Features and benefits

- Top Drill S™ for Steel Machining

- Internal Coolant Channels

- Two margins lands for improved guidance even in though and critical conditions like cross holes and exit on inclined surfaces

- WP20PD grade specific for ISO P materials

- Cylindrical shank h6 tolerance also suitable for shrink fit holders

- Cutting diameter tolerance m7 - suitable as pilot for deep hole drills

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Metric | ||

| tolerance | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Metric | ||

| tolerance | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Inch | ||

| tolerance | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0000/.0005 | .0000/-.0003 | |

| .0000/.0006 | .0000/-.0004 | |

| .0000/.0007 | .0000/-.0004 | |

| .0000/.0009 | .0000/-.0005 | |

| Inch | ||

| tolerance | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0000/.0005 | .0000/-.0003 | |

| .0000/.0006 | .0000/-.0004 | |

| .0000/.0007 | .0000/-.0004 | |

| .0000/.0009 | .0000/-.0005 | |

I have read and accepted the Terms & Conditions of use