Welcome

Please confirm your preferences

Update Preferences

Предложения по продукции

Product Family suggestions

WIDIA At Your Service

Customer Support

Find contact details to customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Уведомления

Отметить все как прочитанные - Change Password

- My Profile

- Logout

Позиции

успешно добавлено в корзину

View Cart

View Cart

WIDIA At Your Service

Customer Support

Find contact details to customer support centers around the globe.

Позиции

успешно добавлено в корзину

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Продукция

- /

- M640 • Фрезы с хвостовиком Weldon

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

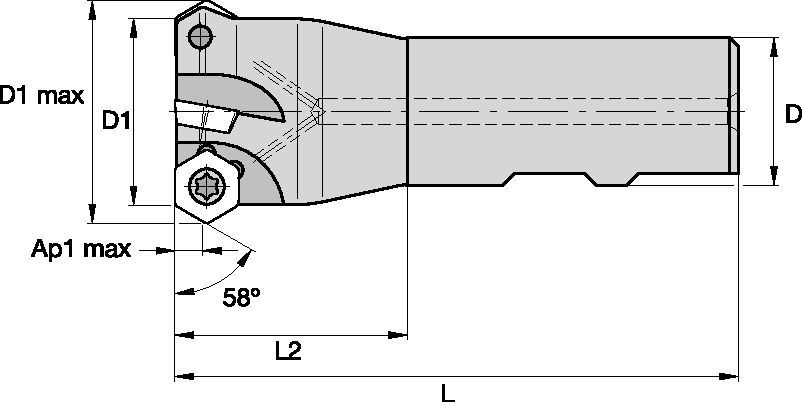

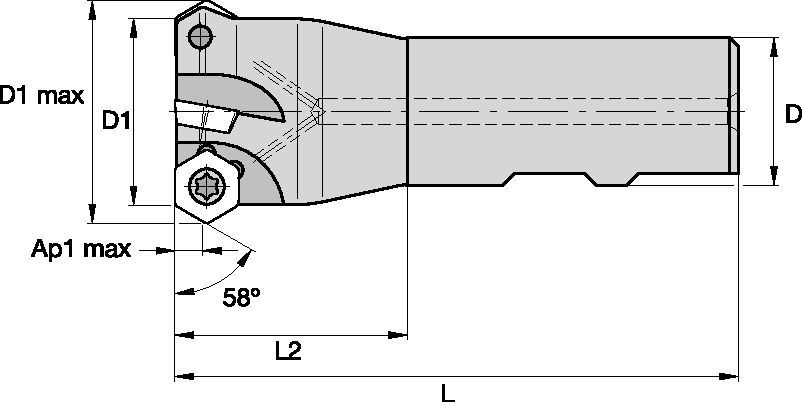

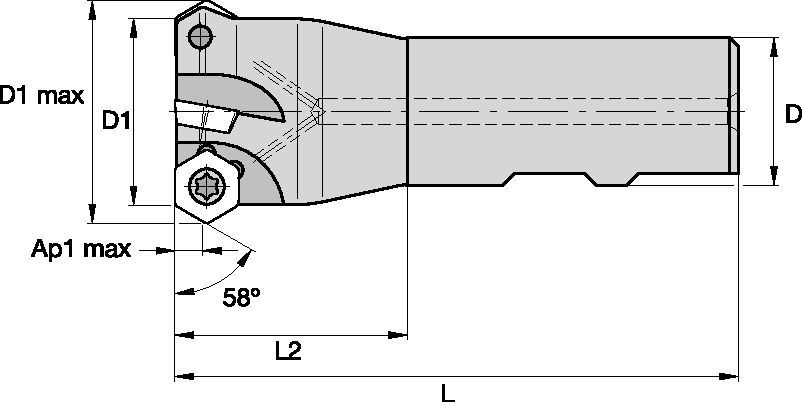

M640 • Фрезы с хвостовиком Weldon

Weldon® End Mills • Metric

Характеристики и преимущества

- 6 режущих кромок.

- Большой передний угол — для применения на маломощных станках или при нежёсткой конструкции детали.

- Стружколомы и марки сплавов для обработки различных материалов.

Использование и область применения

Face Milling

Milling - Through Coolant

Shank - Cylindrical Weldon 2 Flat

Рекомендации по выбору режущих пластин

| Material Group | Light

|

General

|

Heavy

|

|||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..LD | WP40PM | .E..GD | WP40PM | .E..GD | WP40PM |

| P3–P4 | .E..LD | WP25PM | .E..GD | WS40PM | .E..GD | WS40PM |

| P5–P6 | .E..LD | WP25PM | .E..GD | WP25PM | .E..GD | WP25PM |

| M1–M2 | .E..LD | WP25PM | .E..GD | WP25PM | .E..GD | WP25PM |

| M3 | .E..LD | WP40PM | .E..GD | WS30PM | .E..GD | WS30PM |

| K1–K2 | .E..GD | TN6510 | .E..GD | WK15CM | .E..GD | WK15CM |

| K3 | .E..LD | TN6520 | .E..GD | WP25PM | .E..GD | WP25PM |

| N1–N2 | .E..LD | WS40PM | .E..GD | WS40PM | .E..GD | WS40PM |

| N3 | .E..LD | WS40PM | .E..GD | WS40PM | .E..GD | WS40PM |

Рекомендуемые значения подач [мм/зуб]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40

|

||||||||||||

| .F..LDAL | 0,13 | 0,34 | 0,47 | 0,10 | 0,25 | 0,34 | 0,07 | 0,18 | 0,25 | 0,06 | 0,16 | 0,22 | 0,06 | 0,15 | 0,20 | .F..LDAL |

| .E..LD | 0,13 | 0,34 | 0,47 | 0,10 | 0,25 | 0,34 | 0,07 | 0,18 | 0,25 | 0,06 | 0,16 | 0,22 | 0,06 | 0,15 | 0,20 | .E..LD |

| .E..GD | 0,13 | 0,48 | 0,54 | 0,10 | 0,35 | 0,39 | 0,07 | 0,26 | 0,29 | 0,06 | 0,23 | 0,25 | 0,06 | 0,21 | 0,23 | .E..GD |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40

|

||||||||||||

| .F..LDAL | .005 | .013 | .018 | .004 | .010 | .013 | .003 | .007 | .010 | .003 | .006 | .009 | .002 | .006 | .008 | .F..LDAL |

| .E..LD | .005 | .013 | .018 | .004 | .010 | .013 | .003 | .007 | .010 | .003 | .006 | .009 | .002 | .006 | .008 | .E..LD |

| .E..GD | .005 | .019 | .021 | .004 | .014 | .015 | .003 | .010 | .011 | .003 | .009 | .010 | .002 | .008 | .009 | .E..GD |

| Light

|

General

|

Heavy

|

Рекомендуемые значения начальных скоростей резания [м/мин]

| Material Group | TN6510 | TN6520 | TN6525 | TN6540 | WK15CM | |||||||||||

| P | 1 | – | – | – | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | – | – | – |

| 2 | – | – | – | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | – | – | – | |

| 4 | – | – | – | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | – | – | – | |

| 5 | – | – | – | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | |

| 6 | – | – | – | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – |

| 2 | – | – | – | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | |

| K | 1 | 480 | 350 | 260 | 450 | 320 | 230 | 275 | 245 | 220 | 220 | 205 | 180 | 505 | 460 | 410 |

| 2 | 420 | 280 | 205 | 390 | 250 | 190 | 215 | 190 | 180 | 175 | 155 | 140 | 400 | 355 | 330 | |

| 3 | 335 | 260 | 200 | 300 | 230 | 160 | 180 | 160 | 145 | 155 | 145 | 125 | 335 | 300 | 275 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | WP25PM | WP40PM | WS30PM | WS40PM | THM-U | THM | |||||||||||||

| P | 1 | 395 | 340 | 325 | 355 | 310 | 295 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 330 | 290 | 240 | 300 | 260 | 215 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 305 | 260 | 210 | 275 | 235 | 190 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 270 | 220 | 180 | 245 | 205 | 160 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | 220 | 205 | 180 | 205 | 185 | 160 | – | – | – | 205 | 175 | 145 | – | – | – | – | – | – | |

| 6 | 200 | 150 | 120 | 180 | 140 | 110 | – | – | – | 180 | 130 | 95 | – | – | – | – | – | – | |

| M | 1 | 245 | 215 | 200 | 235 | 205 | 185 | 270 | 240 | 220 | 250 | 205 | 170 | – | – | – | – | – | – |

| 2 | 220 | 190 | 155 | 210 | 180 | 150 | 245 | 215 | 175 | 215 | 175 | 145 | – | – | – | – | – | – | |

| 3 | 170 | 145 | 115 | 155 | 140 | 110 | 185 | 160 | 125 | 175 | 130 | 100 | – | – | – | – | – | – | |

| K | 1 | 275 | 245 | 220 | – | – | – | – | – | – | – | – | – | 230 | 205 | 180 | 145 | 110 | 90 |

| 2 | 215 | 190 | 180 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 120 | 85 | |

| 3 | 180 | 160 | 145 | – | – | – | – | – | – | – | – | – | – | – | – | 155 | 115 | 70 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 2400 | 1440 | 1200 | 1080 | 720 | 600 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 1640 | 980 | 800 | 820 | 560 | 460 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 960 | 600 | 480 | 540 | 335 | 240 | |

| S | 1 | 50 | 40 | 30 | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | – | – | – | – | – | – |

| 2 | 50 | 40 | 30 | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | – | – | – | – | – | – | |

| 3 | 60 | 50 | 30 | 60 | 50 | 35 | 65 | 55 | 35 | 60 | 50 | 30 | – | – | – | – | – | – | |

| 4 | 85 | 60 | 40 | 80 | 60 | 40 | 100 | 70 | 50 | 70 | 60 | 35 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | WK15CM | WP25PM | WP40PM | WS30PM | WS40PM | |||||||||||

| P | 1 | – | – | – | 1295 | 1120 | 1060 | 1165 | 1025 | 965 | – | – | – | 915 | 800 | 750 |

| 2 | – | – | – | 1080 | 940 | 785 | 985 | 845 | 710 | – | – | – | 770 | 670 | 555 | |

| 3 | – | – | – | 1000 | 845 | 690 | 905 | 770 | 630 | – | – | – | 705 | 605 | 490 | |

| 4 | – | – | – | 890 | 725 | 590 | 805 | 670 | 535 | – | – | – | 635 | 520 | 425 | |

| 5 | – | – | – | 725 | 670 | 590 | 670 | 610 | 535 | – | – | – | 520 | 455 | 425 | |

| 6 | – | – | – | 650 | 490 | 395 | 590 | 450 | 355 | – | – | – | 455 | 360 | 275 | |

| M | 1 | – | – | – | 805 | 710 | 650 | 770 | 670 | 610 | 890 | 785 | 725 | 850 | 620 | 375 |

| 2 | – | – | – | 725 | 630 | 510 | 690 | 590 | 490 | 805 | 710 | 570 | 750 | 555 | 340 | |

| 3 | – | – | – | 550 | 475 | 370 | 510 | 450 | 355 | 610 | 535 | 415 | 620 | 455 | 260 | |

| K | 1 | 1655 | 1520 | 1340 | 905 | 805 | 725 | – | – | – | – | – | – | – | – | – |

| 2 | 1320 | 1165 | 1080 | 710 | 630 | 590 | – | – | – | – | – | – | – | – | – | |

| 3 | 1105 | 985 | 905 | 590 | 535 | 475 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 3525 | 3100 | 3100 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 3100 | 2870 | 2770 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 2870 | 2490 | 2490 | |

| S | 1 | – | – | – | 155 | 140 | 95 | 155 | 140 | 120 | 180 | 155 | 120 | 200 | 145 | 85 |

| 2 | – | – | – | 155 | 140 | 95 | 155 | 140 | 120 | 180 | 155 | 120 | 180 | 130 | 85 | |

| 3 | – | – | – | 200 | 155 | 95 | 200 | 155 | 120 | 215 | 180 | 120 | 205 | 150 | 95 | |

| 4 | – | – | – | 275 | 200 | 140 | 260 | 200 | 140 | 335 | 235 | 155 | 295 | 215 | 135 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Material Group | THM | THM-U | TN6510 | TN6520 | TN6525 | TN6540 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | |

| K | 1 | 475 | 355 | 295 | 750 | 670 | 590 | 1570 | 1140 | 845 | 1475 | 1045 | 750 | 905 | 805 | 725 | 725 | 670 | 590 |

| 2 | 490 | 395 | 275 | – | – | – | 1380 | 925 | 670 | 1280 | 830 | 630 | 710 | 630 | 590 | 570 | 510 | 450 | |

| 3 | 510 | 370 | 235 | – | – | – | 1105 | 845 | 650 | 985 | 750 | 535 | 590 | 535 | 475 | 510 | 475 | 415 | |

| N | 1 | 3540 | 2365 | 1970 | 7870 | 4720 | 3935 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 2695 | 1830 | 1520 | 5370 | 3210 | 2615 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 1770 | 1105 | 785 | 3150 | 1970 | 1570 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 155 | 120 | 95 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 80 | 60 | 40 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 140 | 95 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 200 | 95 | 80 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |